Horizontal fluidized bed waste heat recovery device for blast furnace granulated slag

A waste heat recovery device and granulated slag technology, applied in fluidized bed heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problem of low glass body content of cooling slag, low waste heat recovery efficiency, and inability to operate continuously To achieve the effect of ensuring the fluidization effect, avoiding waste, and improving the efficiency of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be implemented in many different forms and is not limited to the embodiments described in this specification. On the contrary, these embodiments are provided to make the understanding of the present disclosure more thorough and comprehensive.

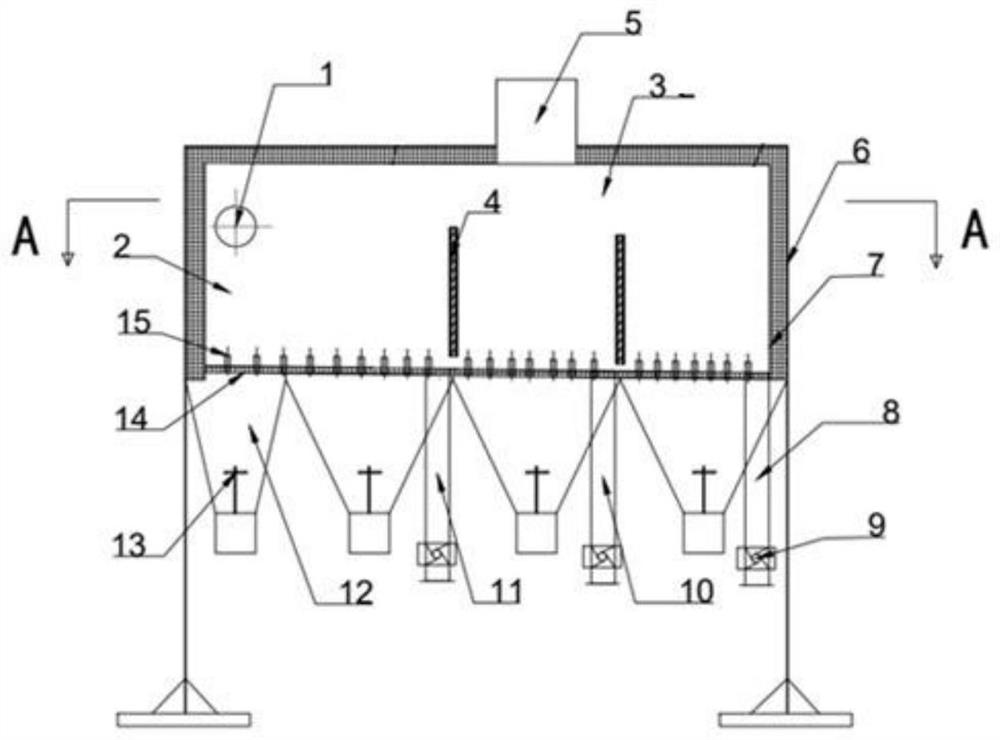

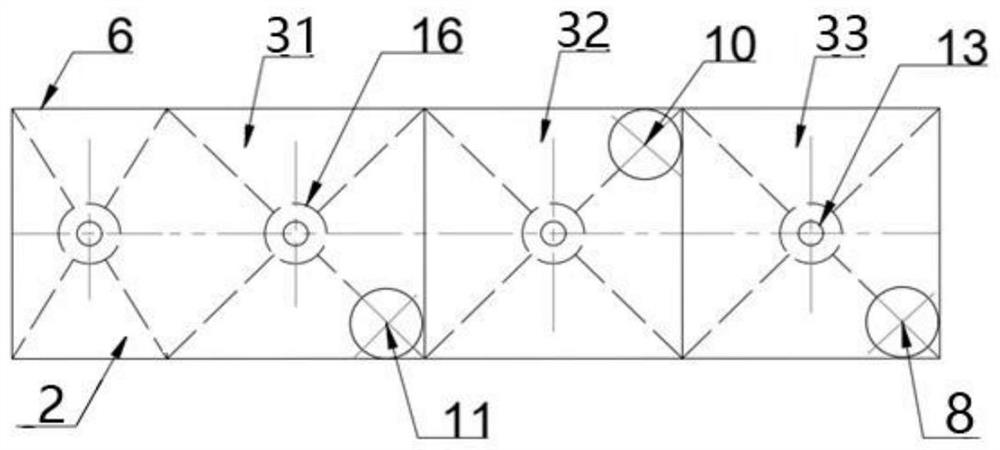

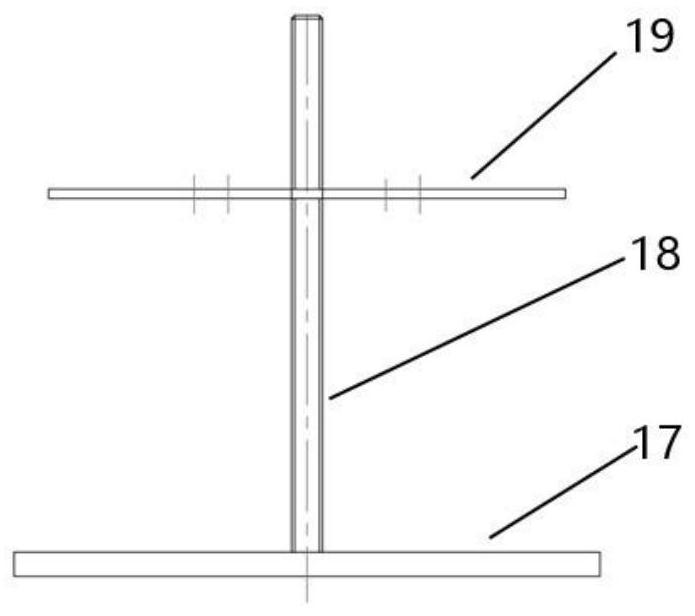

[0023] The blast furnace granulated slag horizontal fluidized bed waste heat recovery device provided in this embodiment has the following structure: figure 1 As shown, it mainly includes a fluidized heat exchange bed made of a bracket 6 and a heat-resistant and wear-resistant material 7, an air distribution device composed of a hood-type air distribution plate 14 and a hood 15, and an air chamber 12, a fan and a pre-dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com