Multi-layer automatic water pouring machine

A water pouring machine and automatic technology, applied in heat treatment equipment, manufacturing tools, quenching devices, etc., can solve the problems of unfavorable operators, high labor intensity, and harsh working conditions, etc., achieve convenient and reliable operation, solve continuous operation, reduce input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

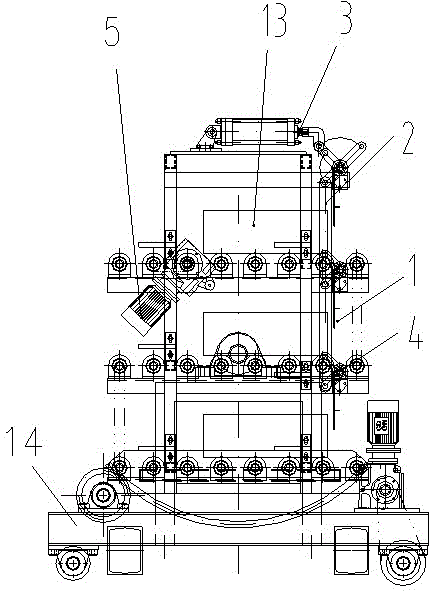

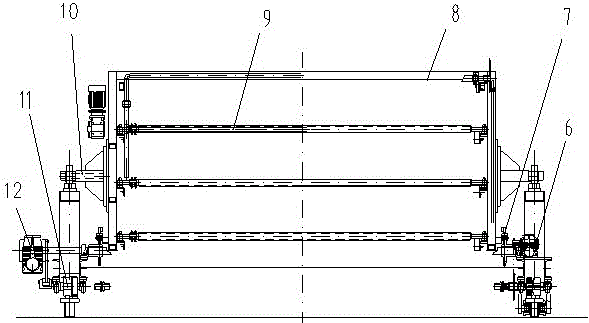

[0022] combine figure 1 Illustrate that the structure of the multi-layer automatic pouring machine of the present invention is described in detail:

[0023] Such as figure 1 , figure 2 As shown, the multi-layer pouring mechanism of the present invention includes a fixed frame 14 and an overturning frame driven by a support shaft 10 and an overturning drive mechanism, wherein the overturning frame adopts a trolley bracket 8 . There are at least two layers of pouring platforms for workpieces in the turning frame. In this embodiment, the pouring platforms have three layers, but it can also be two or more layers. The water pouring platform is made of rollers 9, which are driven by the roller drive motor 5 to rotate, and the (disk-shaped material) workpiece 13 is transported from other equipment to the middle position of the rollers 9, and the turning cylinder 3 passes through the connecting rod. 2 Turn the baffle plate 1 fixedly connected with the synchronous shaft 3 downwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com