Robot system for inspection of overhead power line

A technology for inspecting robots and power lines, which is applied in closed-circuit television systems, overhead lines/cable equipment, etc., can solve problems such as high costs and increase technical difficulties, and achieve the effect of accurately detecting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The overhead power line inspection robot system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

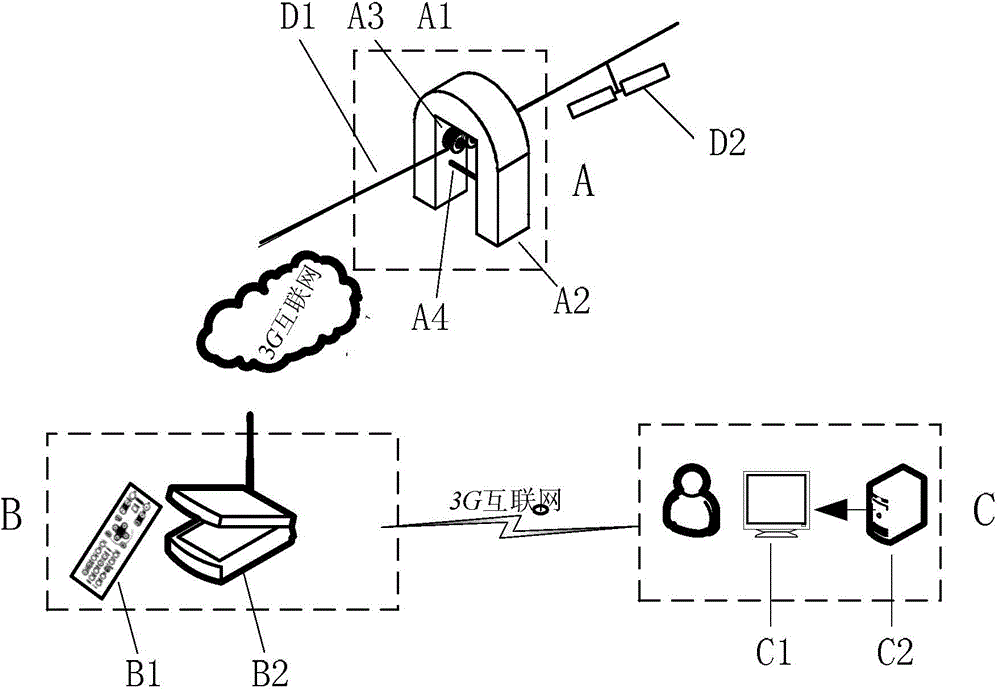

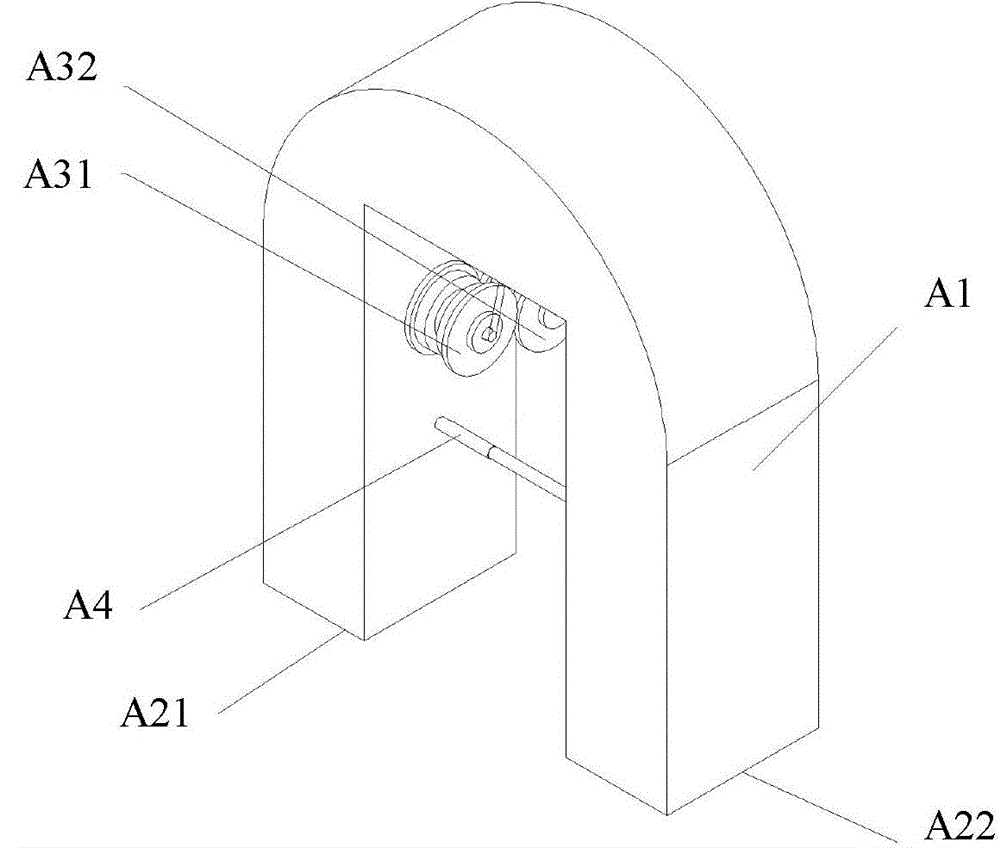

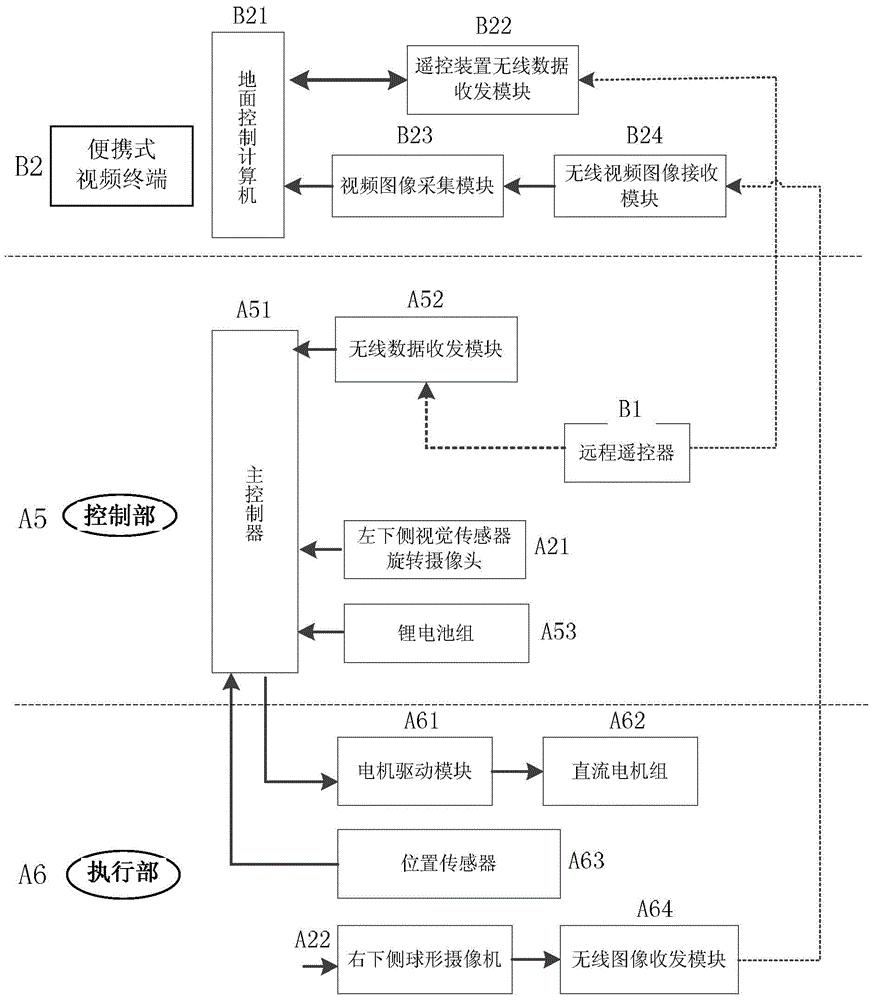

[0028] Such as figure 1 — image 3 As shown, the overhead power line inspection robot system provided by the present invention includes: an online execution system A, a vehicle-mounted portable base station B, and a ground data management center C; wherein the online execution system A includes: an n-type suspension box A1, a camera A2, Roller A3, protective telescopic shaft A4 and control drive device; wherein: n-type suspension box A1 is an n-shaped casing, the top of the opening in the middle is provided with a roller A3, and the bottom of the roller A3 is provided with a protective telescopic shaft A4; n-type The interior of the suspension box A1 is equipped with a control drive device; the camera A2 includes visual sensors installed on the lower ends of the left and right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com