Low-thermal-resistance low-cost automobile solid-state relay

A solid-state relay, low-cost technology, used in relay ventilation/cooling/heating, relay base/shell/cover, etc., can solve the problems of high cost of heat dissipation materials, small current capacity, poor heat dissipation capacity of solid state relays, etc. Heat dissipation effect, rapid heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

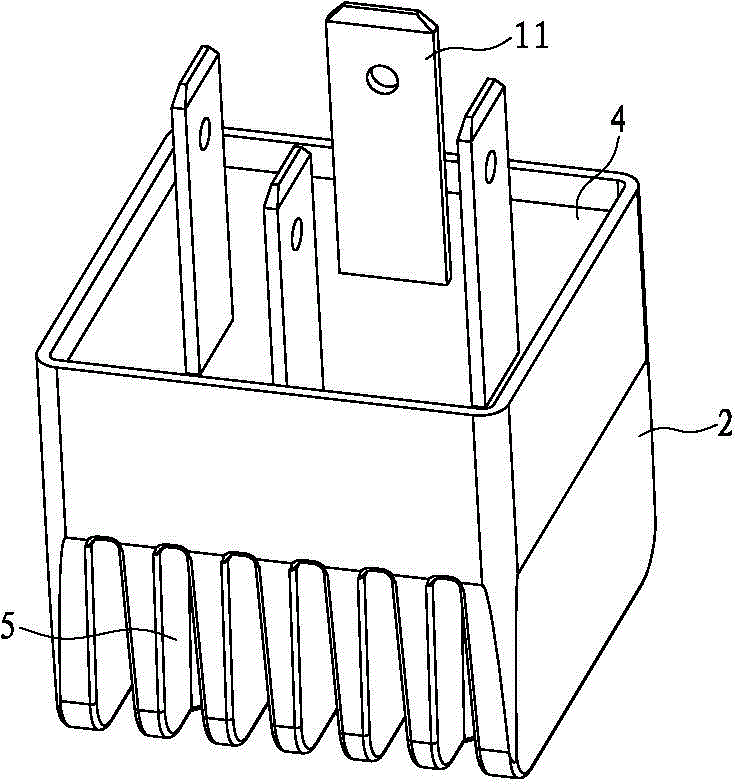

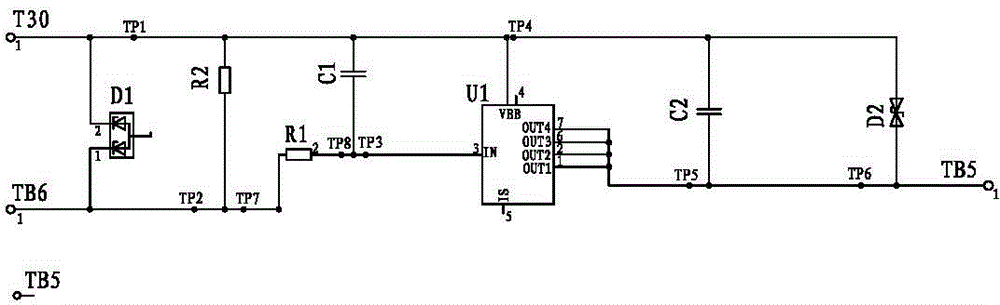

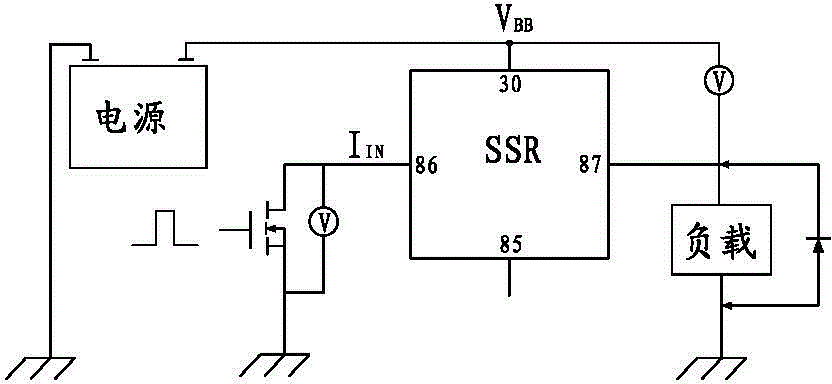

[0046] refer to Figures 1 to 13b As shown, a low thermal resistance and low cost vehicle solid state relay disclosed by the present invention includes a circuit board 1 with electrical connection terminals 11 and a heat dissipation case 2 with a cavity 21 .

[0047] The circuit board 1 is sealed and installed in the cavity 21 of the heat dissipation shell 2. In this embodiment, as Figure 9 and Figure 10 As shown, a step 22 is formed on the side walls around the cavity 21 of the heat dissipation housing 2, and a gap is formed between the step 22 and the bottom of the cavity 21, as Figure 11 As shown, the thermally conductive insulating glue 3 fills the gap, and seals and fixes the circuit board 1 at the bottom of the cavity 21 . The installation structure of the circuit board 1 makes the installation of the circuit board 1 relatively sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com