Control bus system for neutral beam injector system

A neutral beam injector and control bus technology, which is applied in the field of auxiliary heating neutral beam injector system control, can solve the problems of too many signal wirings, poor anti-electromagnetic interference capability, and inability to achieve hot swapping, etc., and achieves a compact structure. , Improve the effect of anti-electromagnetic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

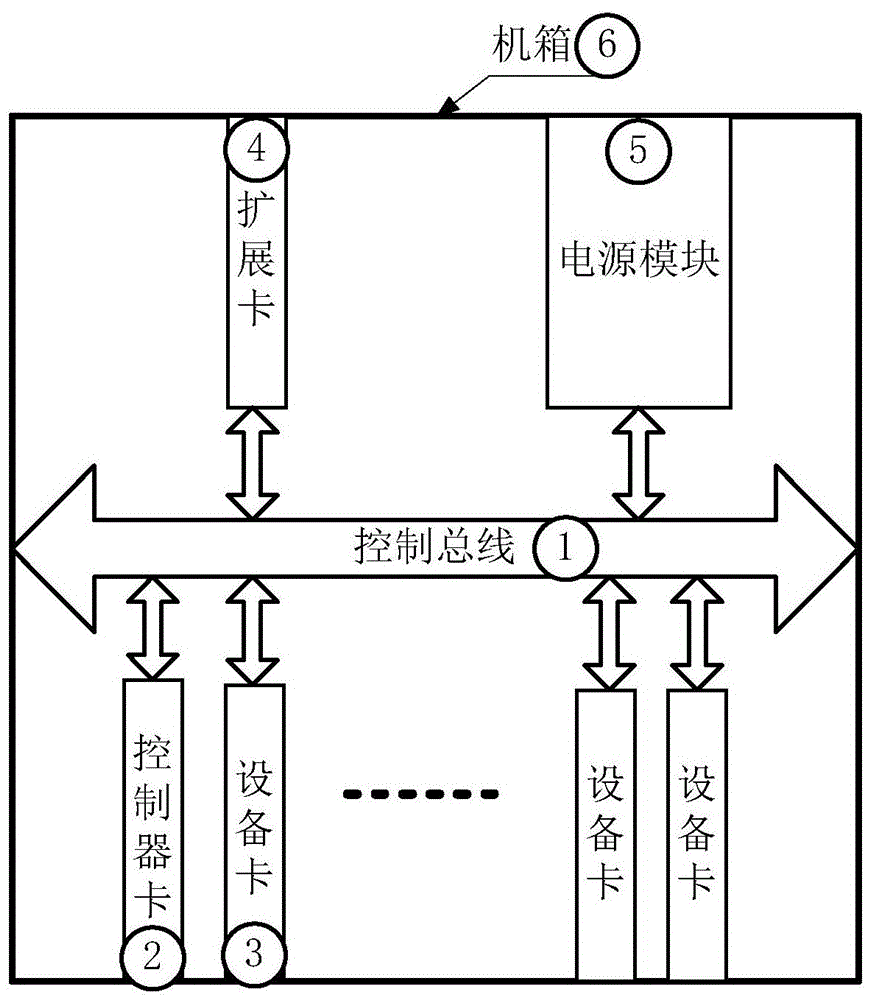

[0018] see figure 1 , a neutral beam injector system control bus system, including a chassis 6 and a bus backplane 1, a bus backplane 1 is installed in the middle of the chassis 6, a control bus is fixed on the bus backplane 1, and the bus Both sides of the backplane 1 are provided with control bus interfaces, and also include a controller card 2, a device card 3, an expansion card 4 and a power supply module, and the controller card, equipment card, expansion card and power supply module are inserted in the control bus interface through the control bus interface. Both sides of the bus backplane;

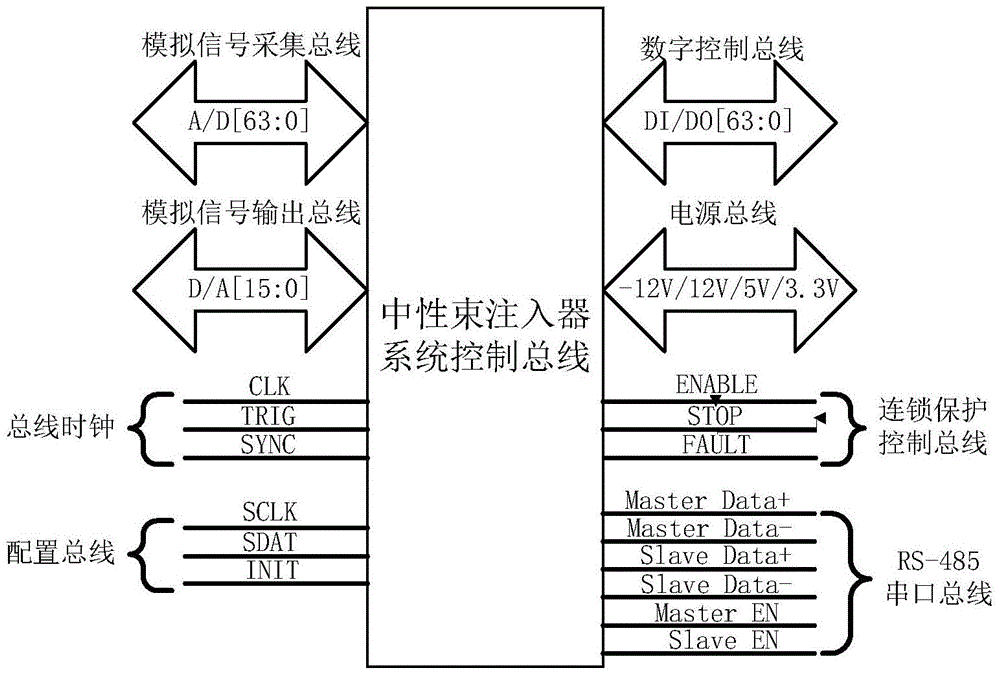

[0019] The control bus is a key part of the control bus of the neutral beam injector system, such as figure 2 shown. The system control bus is composed of digital control bus, chain protection control bus, analog signal output bus, analog signal acquisition bus, communication bus, bus clock and power bus. The main control chassis can be connected to the expansion chassis through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com