Mobile HSE inspection method based on explosion-proof hand-held terminal

A handheld terminal and inspection method technology, applied in the field of mobile HSE inspection, can solve problems such as poor supervision and non-standard HSE inspection, and achieve the effect of enhancing applicability, full scalability, and optimizing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

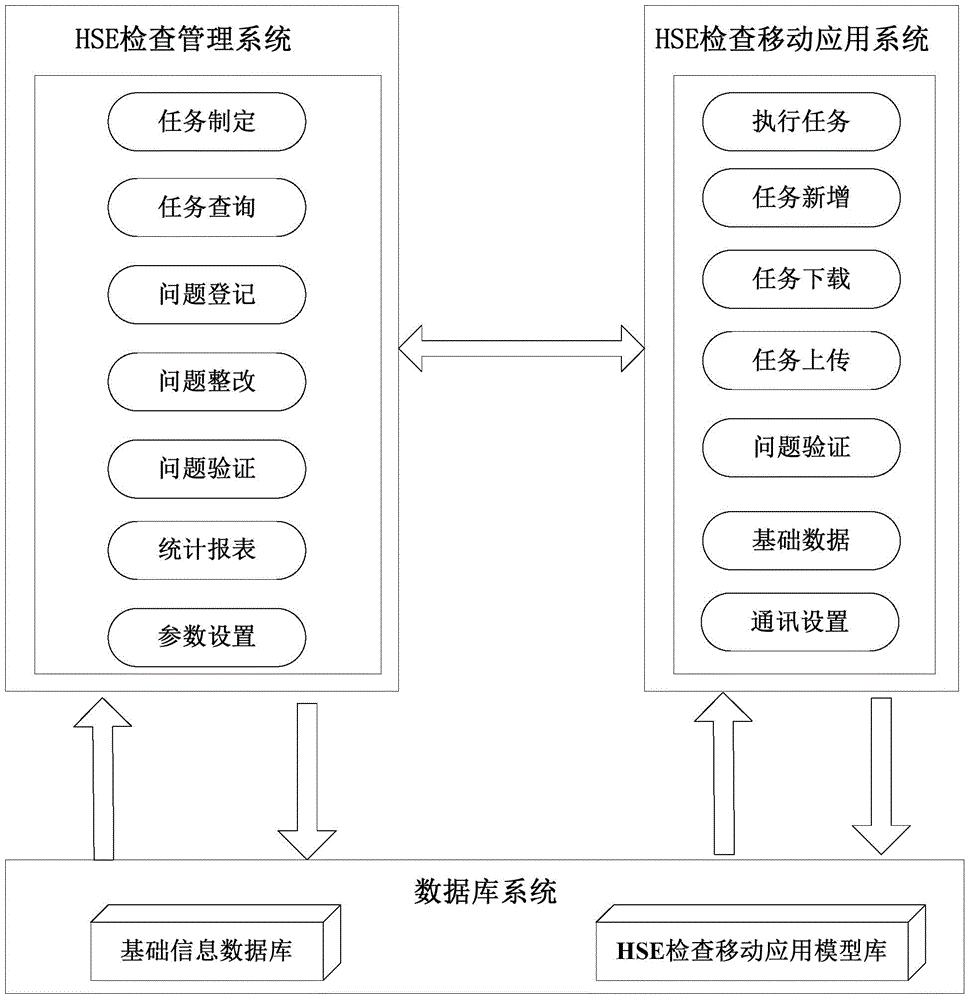

[0037] The mobile HSE inspection method based on the explosion-proof handheld terminal adopts such as figure 1 In the frame diagram shown, the user connects to the HSE inspection platform through the network to realize the HSE inspection based on the explosion-proof handheld terminal; the HSE inspection platform mainly includes the network, database system, HSE inspection management system and mobile HSE inspection application system, in which the network is connected with The database system, the HSE inspection management system and the mobile HSE inspection application system are connected. The database system includes the basic information database and the HSE inspection mobile application model library, and the HSE inspection management system is responsible for the daily HSE inspection task formulation, problem registration, problem rectification, problem Verification, statistical reports and parameter settings, the HSE inspection mobile application system is a mobile mana...

specific Embodiment approach

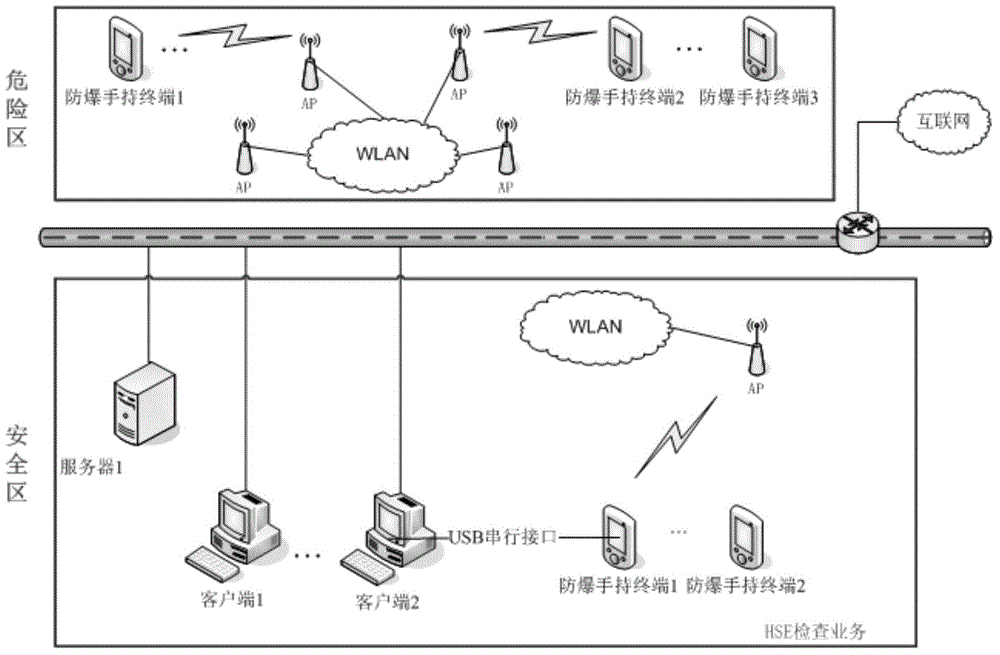

[0041] Server 1 refers to the server of the mobile HSE inspection system based on explosion-proof handheld terminals; clients 1-2 represent personnel of different roles participating in the enterprise's HSE inspection, and mobile terminals 1-5 represent personnel of different roles participating in the enterprise's HSE inspection mobile application . For example: client 1 represents the HSE supervisor of the grassroots unit, client 2 represents the safety officer of the grassroots unit; mobile terminal 1 represents the on-site HSE inspector, mobile terminal 2 represents the safety officer of the grassroots unit, and mobile terminal 3 represents the HSE supervisor of the grassroots unit of the enterprise. The mobile terminal 4 represents the security officer of the basic unit. The client logs in to server 1 by entering the user name. According to different login roles, the system provides different HSE inspection management service menus and permissions.

[0042] The above sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com