Pressure sensor forming method

A pressure sensor and electrode layer technology, which is applied in the fluid pressure measurement, instrument, and measurement force using capacitance change, can solve problems such as poor performance of the pressure sensor, and achieve the effect of eliminating adverse effects, reducing resistivity, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

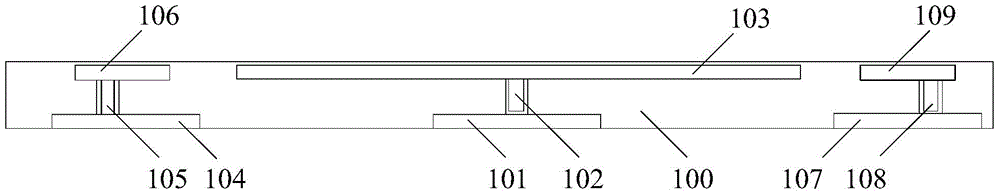

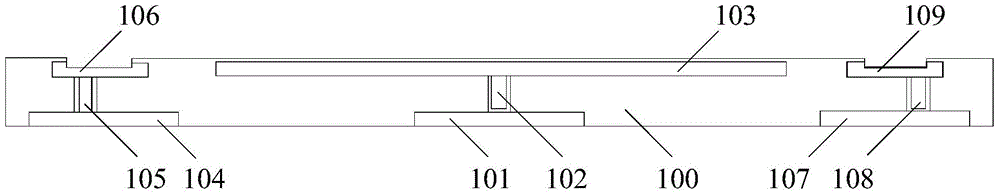

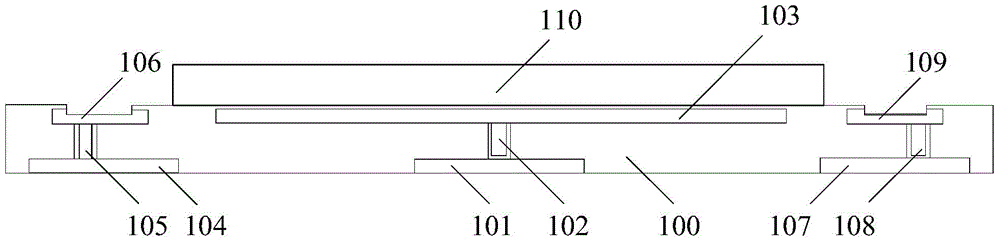

[0028] As mentioned in the background, existing methods form pressure sensors with poor performance. After further analysis of the reasons, it turns out that the existing method usually adopts the furnace tube process to form the top electrode layer of the pressure sensor. However, the top electrode layer formed by the furnace tube process has relatively large internal stress and high resistivity. The top electrode layer is used as the upper plate of the chamber for sensing pressure changes (the chamber is located between the bottom electrode and the top electrode), and its internal stress is required to be as low as possible so that accurate pressure changes can be obtained. At the same time, its resistance is required As low as possible, so that better conductivity characteristics can be obtained. However, if the internal stress of the top electrode layer is large, it is easy to crack itself, making the pressure sensor invalid. Even if the top electrode layer is not cracked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com