Flat window cooling tape and heat exchange system for installing flat window cooling tape

A technology of heat dissipation belt and flat window, which is applied in the field of heat exchange system, can solve the problems such as the inability to lengthen the window length of the heat dissipation belt, the unreasonable distribution of heat conduction points at the wave top, and the influence of the heat dissipation capacity of each component, so as to achieve a reasonable distribution of heat conduction points and a structure. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

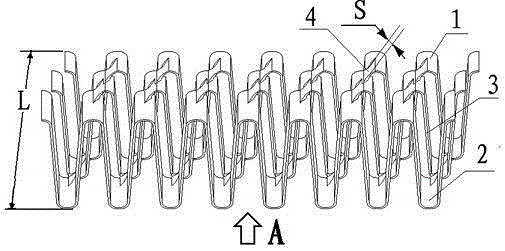

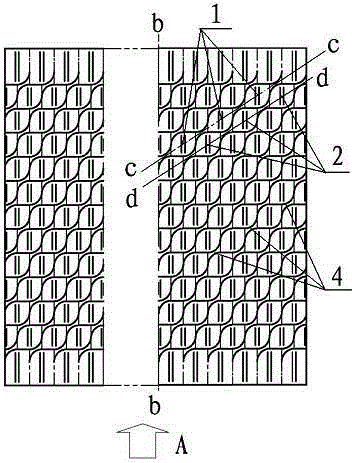

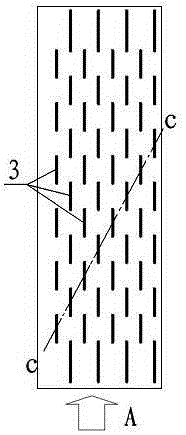

[0017] Examples of the present invention figure 1 , figure 2 , image 3 As shown, the heat dissipation belt is wavy with a uniform wave pitch, and a waveform of the heat dissipation belt includes a wave top 1, a wave bottom 2, a window 3, and a connecting belt 4; the center lines bb of each window are parallel to each other and parallel to the airflow A direction; the window length L is equal to the distance between wave top 1 and wave bottom 2; each window 3 is parallel to the window centerline bb, and the angle between it and the airflow A direction is 0°; adjacent windows on a waveform 3 is connected by connecting belt 4, and the width S of the connecting belt is 2mm; the window of the heat dissipation belt 3 is only connected by the connecting belt 4 between the wave top and the adjacent wave top on one waveform of the heat dissipation belt, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com