Induction cooker panel

An electromagnetic cooker and panel technology, applied in the field of electromagnetic cookers, can solve the problems of peeling, discoloration of the ink layer, foaming, etc., and achieve the effects of small expansion coefficient, improved service life, and thin ink layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

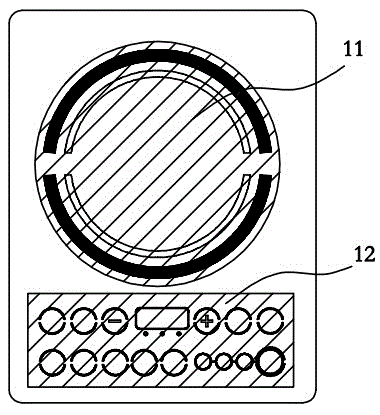

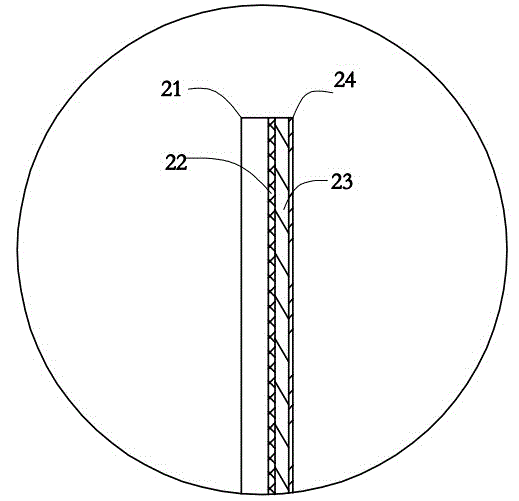

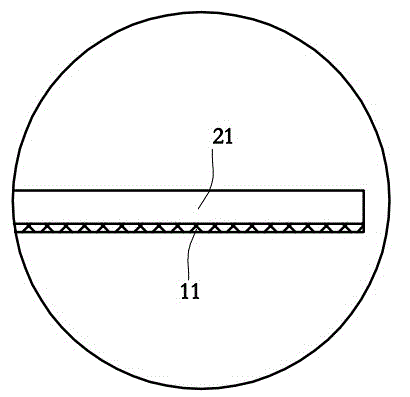

[0021] Such as figure 1 , 2 As shown in and 3, a panel 21 of an induction cooker, the first ink layer 11 is arranged in the corresponding area of the pot, and the ink layer is a high temperature resistant ink layer, which can withstand high temperatures above 700 degrees, and its thickness is 0.01 mm to 0.1 mm; The second ink layer 12 is provided in the display and control area and glue area other than the corresponding area. The ink layer has a temperature resistance range of 100°C to 450°C and a thickness of about 0.15 mm to 0.21 mm.

[0022] Among them, such as figure 1 As shown, the corresponding area of the pot is circular, and the first ink layer is also circular. According to the inventive idea of the present invention, it is easy to think of replacing the circle with other elliptical structures or polygonal structures. It is worth noting that the area of the corresponding area of the pot should be greater than or equal to the area of the contact surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com