Brake block steel sheet and friction layer used in cooperation with brake block steel sheet

A technology of brake pads and friction layers, which is applied in the field of automobile parts manufacturing and automobile manufacturing, can solve the problems of expensive brake pad replacement and maintenance, and achieve the effect of reducing replacement and maintenance costs and reducing replacement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

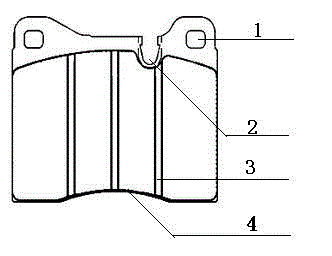

[0024] Such as figure 1 As shown, the brake pad steel sheet includes a brake pad fixing part and a friction layer fixing part. The brake pad fixing part is located at the front section of the steel plate and includes a mounting hole 1 and a mounting groove 2 adapted to the car body. The fixed part of the friction layer is located in the middle section and the rear section of the steel plate. Three rectangular grooves 3 are opened on the steel plate of the fixed part of the friction layer, and the tail end of the rectangular groove is provided with a closed buckle 4 .

Embodiment 2

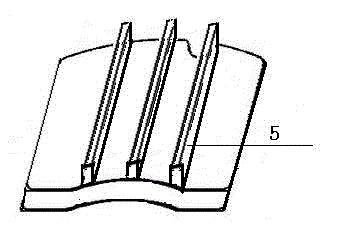

[0026] Such as figure 2 As shown, the friction layer is provided with a raised ridge 5, and the raised ridge is adapted to the rectangular groove body 3 of the brake pad steel sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com