Fan system

A fan system and sensing unit technology, applied in cooling/ventilation/heating transformation, pump control, non-variable pumps, etc., can solve the problem of communication chassis and servo cabinets unable to dissipate heat, uneven temperature, and excessive cavity weight And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

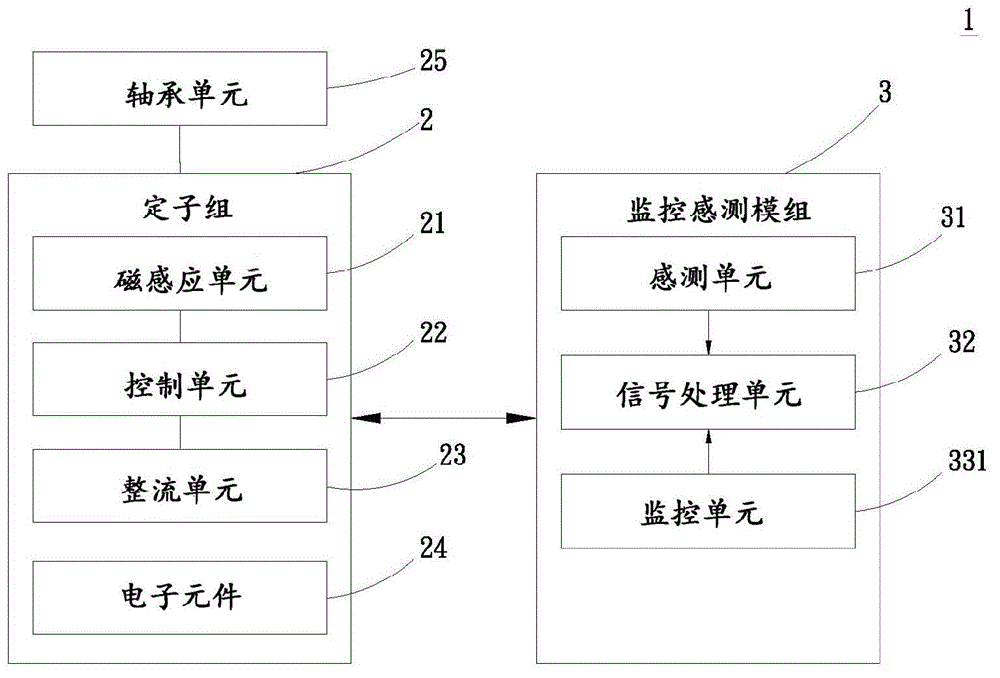

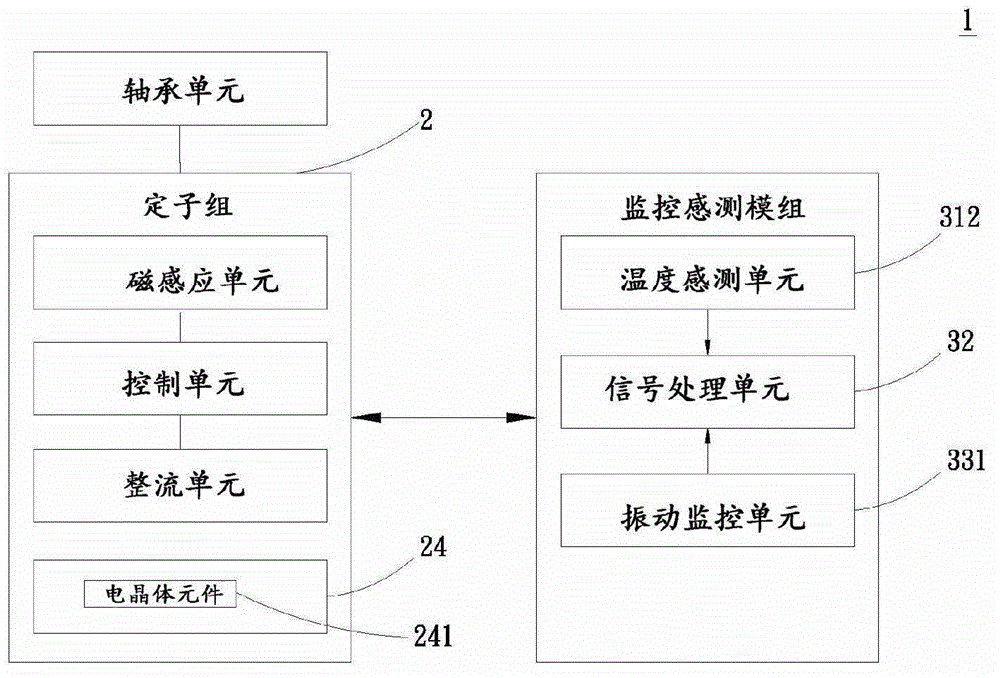

[0046] The present invention provides a fan system, please refer to figure 1 Shown is a schematic block diagram showing the first preferred embodiment of the present invention Figure 1 , wherein the fan system 1 includes a stator group 2 and a monitoring and sensing module 3 .

[0047] Wherein the stator group 2 includes a magnetic induction unit 21, a control unit 22, a rectification unit 23 and a plurality of electronic components 24 and is provided with a bearing unit 25. In this embodiment, its magnetic induction unit 21 is a Hall element, and the magnetic induction The unit 21 is electrically connected to the control unit 22, the control unit 22 is a microcontroller, and the control unit 22 is electrically connected to the rectification unit 23, and the rectification unit 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com