Heating floor and manufacturing method thereof

A ground and construction method technology, applied in the fields of construction, ground insulation, and winter heating, can solve the problems of low heating efficiency, poor thermal insulation effect, and large floor area, so as to achieve safe use, not affect wall decoration, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

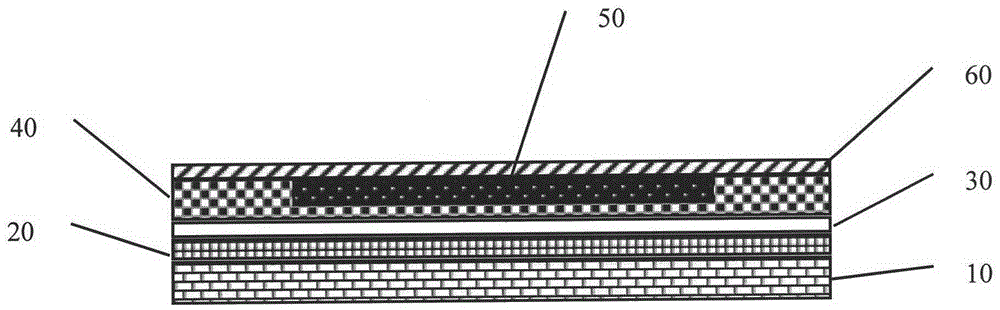

[0015] A heating floor is composed of ground, vacuum insulation board, glass fiber cloth, cement board, conductive heating mud and wooden floor from bottom to top.

[0016] A construction method for a heating floor, which is characterized in that it includes the following steps: leveling the bottom of the room, laying an 8mm thick vacuum insulation board on the ground, laying a layer of glass fiber cloth on the vacuum insulation board, and laying a 7mm thick vacuum insulation board on the glass fiber cloth. Cement board with a rectangular groove in cross section, the rectangular groove is 5mm deep and 15mm wide, and the guide groove has a back-shaped structure; the inside of the back-shaped guide groove is filled with conductive heating mud, with a thickness of 3mm and a width of 10mm; after the conductive heating mud is dried, the wooden floor is laid , The distance between the bottom surface of the wooden floor and the upper surface of the heating mud plane is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com