A wall structure for protecting spent fuel pools

A technology of spent fuel pool and wall structure, applied in the direction of walls, building components, building structures, etc., can solve the problem of affecting the wall structure of the spent fuel pool, falling on the bottom plate of the loading well or cleaning well, affecting the spent fuel pool Problems such as the normal operation of process equipment, to achieve the effect of lengthening the force transmission path, simple structure and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

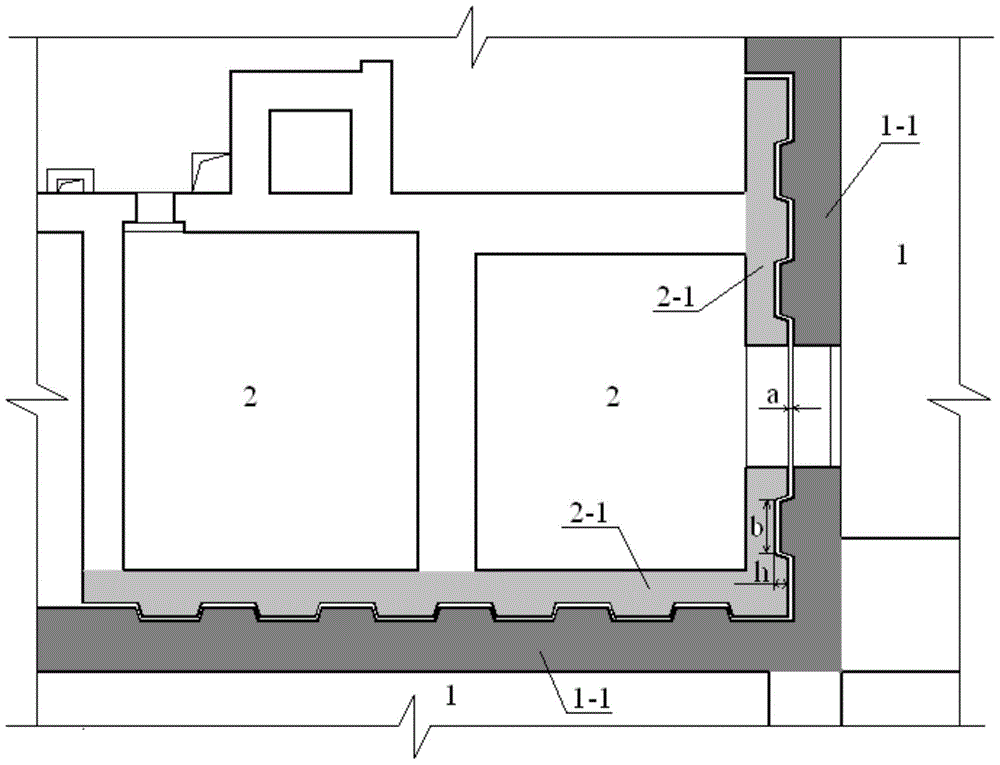

[0013] The present invention relates to a wall structure of a spent fuel pool 1, wherein the periphery of the spent fuel pool 1 is provided with an auxiliary well 2 connected thereto for loading or cleaning spent fuel, such as a container loading well and a container cleaning well.

[0014] Such as figure 1 As shown, a wall structure for protecting a spent fuel pool provided by the present invention includes a wall 1-1 constituting a spent fuel pool 1 and a wall 2-1 constituting an auxiliary well 2, constituting a spent fuel The wall 1-1 of the pool 1 and the wall 2-1 constituting the auxiliary well 2 jointly form a double-wall tooth-shaped occlusal structure. There are toothed gaps of equal width between the body of walls 2-1 of 2.

[0015] In the present invention, the wall 1-1 constituting the spent fuel pool 1 and the wall 2-1 constitutin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com