Mixed single-denier tow for reduced-focus cigarette filter rods and its preparation method and application

A cigarette filter rod and tow technology, which is applied in the field of mixed single-denier tow for reduced-focus cigarette filter rods and its preparation, can solve the problems of high cost, complex production process of special-shaped filter rods, and low production efficiency, and achieve effective operation High efficiency, stable decoking efficiency and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

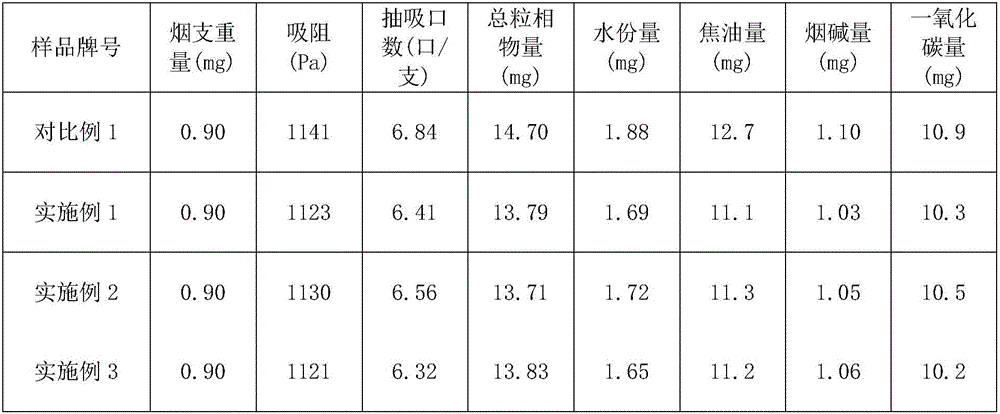

Embodiment 1

[0022] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with an X-shaped cross-section. The vinegar sheet is dissolved in acetone to form a slurry, the slurry is filtered, and then enters the spinning equipment, and passes through the same spinneret. The spinneret holes with different apertures are spun to form three kinds of monofilaments with different cross-sectional shapes and monofilament linear densities. The spinneret holes with three different apertures are required to be evenly distributed in the same spinneret according to the weight ratio; The monofilament linear densities described above are 2.3dtex, 2.7dtex, and 3.0dtex respectively, and the ratio is 1:1:1. The cross-sectional shape of the monofilament is X-type, Y-type and O-type. Bundling, drying, spinning, and packaging finally produce a finished product of mixed single-denier fiber tow. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water content...

Embodiment 2

[0024] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with an X-shaped cross-section. The vinegar sheet is dissolved in acetone to form a slurry, the slurry is filtered, and then enters the spinning equipment, and passes through the same spinneret. The spinneret holes with different apertures are spun to form three kinds of monofilaments with different cross-sectional shapes and monofilament linear densities. The spinneret holes with three different apertures are required to be evenly distributed in the same spinneret according to the weight ratio; The monofilament linear densities described above are 2.3dtex, 2.7dtex, 3.0dtex, and the ratio is 1:1:1. The cross-sectional shape of the monofilament is X-type, X-type and O-type. Bundling, drying, spinning, and packaging finally produce a finished product of mixed single-denier fiber tow. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water content is (6.0±1.6)%, t...

Embodiment 3

[0026] A method for preparing mixed single-denier tows for reduced-focus cigarette filter rods with an X-shaped cross-section. The vinegar sheet is dissolved in acetone to form a slurry, the slurry is filtered, and then enters the spinning equipment, and passes through the same spinneret. The spinneret holes with different apertures are spun to form three kinds of monofilaments with different cross-sectional shapes and monofilament linear densities. The spinneret holes with three different apertures are required to be evenly distributed in the same spinneret according to the weight ratio; The monofilament linear densities described above are 2.3dtex, 2.7dtex, and 3.0dtex, respectively, and the ratio is 1:1:1. The cross-sectional shape of the monofilament is Y-shaped, Y-shaped and O-shaped. Bundling, drying, spinning, and packaging finally produce a finished product of mixed single-denier fiber tow. The breaking strength of the mixed single denier tow is ≥18.0N / Ktex, the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com