A method of making microchannel plate functional layer by atomic layer deposition technology

An atomic layer deposition and microchannel plate technology, applied in the field of functional layers, can solve the problems of short lifespan, unstable performance, and complicated fabrication of microchannel plate functional layers, and achieve the effect of prolonging lifespan, improving production efficiency, and having a dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

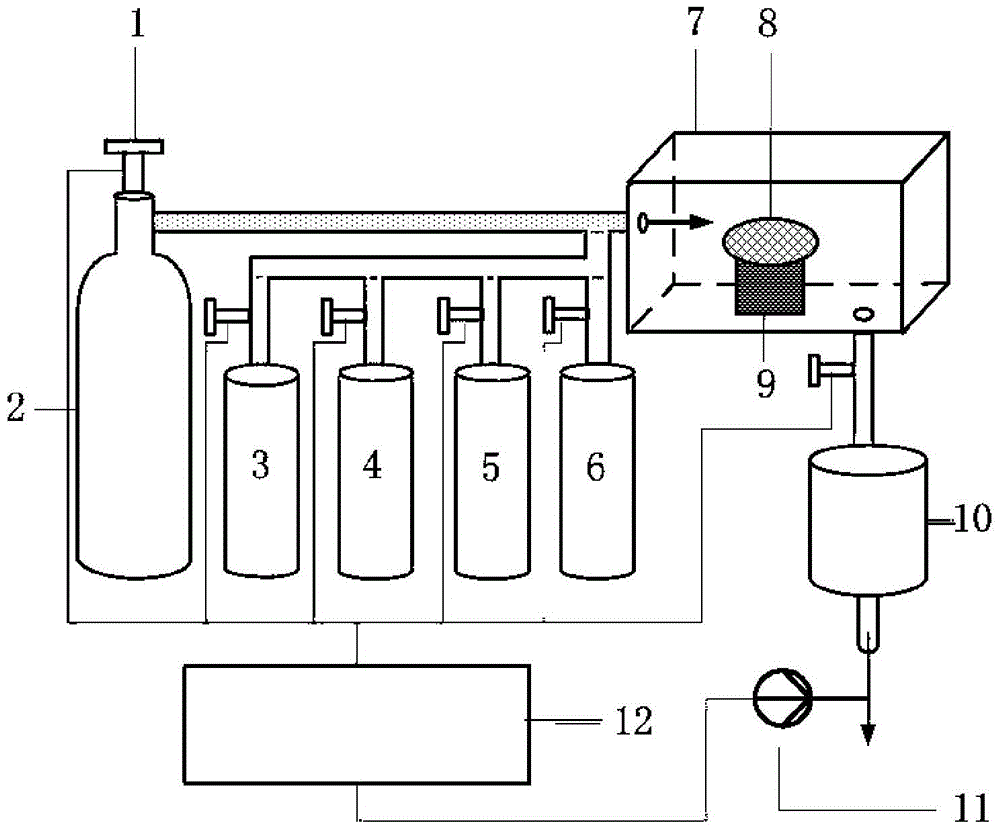

[0043] The atomic layer deposition technology produces the resistance layer and the emission layer of the microchannel plate, which has extremely high precision requirements for various operations and parameters in the preparation process. Such as figure 1 As shown, according to the set procedure, the control system first opens the valve of the clean gas device to feed the clean gas into the vacuum chamber, and at the same time opens the valve of the vacuum pump pipeline to remove impurity gas, and at the same time detects the composition and concentration of the exhaust gas. When the concentration of clean gas in the exhaust gas reaches the set threshold, close the valve of the vacuum pump pipeline, and then close the valve of the clean gas device.

[0044] Then according to the doping sequence DEZ / TMA / H 2 O, Al-Zn doping ratio 19:1, exposure time DEZ / N 2 / H 2 O / N 2 =0.1s / 3s / 0.1s / 4s, TMA / N 2 / H 2 O / N 2 =0.1s / 3s / 0.1s / 4s, DEZ / N 2 / TMA / N 2 / H 2 O / N 2 =0.1s / 3s / 0.1s / 3s / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com