High temperature-resistant low viscosity pressure-sensitive adhesive used for protection films, and preparation method and application thereof

A pressure-sensitive adhesive and protective film technology, applied in the field of pressure-sensitive adhesives, can solve the problems of high temperature resistance and increased peeling force, and achieve the effects of convenient secondary processing, small growth and low peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A kind of preparation method of the high-temperature-resistant low-viscosity pressure-sensitive adhesive that is used for protective film of the present invention, it comprises the steps:

[0057] S1. Mix the basic monomer and the modified monomer in proportion to form a mixed solution;

[0058] S2. prepare the organic solution of initiator;

[0059] S3. preparing an organic solvent;

[0060] S4. In parts by mass, 1 / 3 of the mixed solution, 1 / 3 of the organic solution of the initiator, and at least 2 / 3 of the organic solvent are added to the reactor for reaction, and then the remaining mixed solution and the initiator are added dropwise Put the organic solution in the reactor, keep it warm after the dropwise addition, when the remaining organic solvent is left, add the remaining organic solvent dropwise in the reactor, after the dropwise addition, cool down and filter the material to obtain the target product.

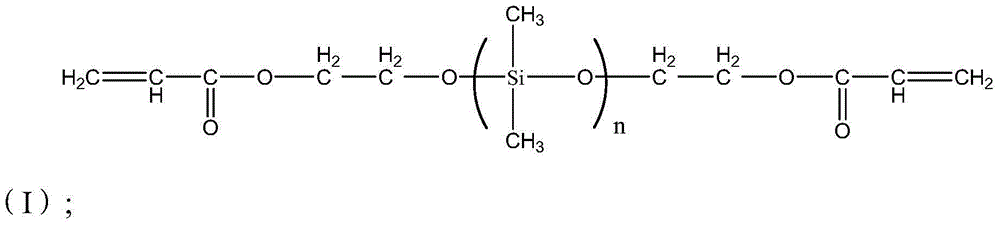

[0061] In the present invention, silicones with double b...

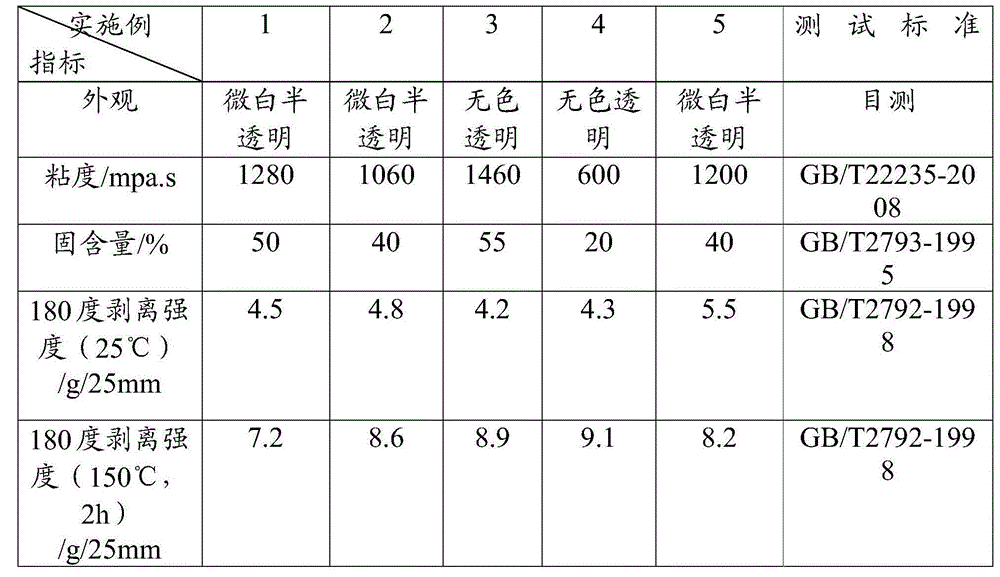

Embodiment 1

[0076] Mix 70 g of n-butyl acrylate, 22 g of isooctyl acrylate, and 2 g of stearyl methacrylate to prepare basic monomers. Mix 4 g of silicone with double bonds at both ends with a molecular weight of 1000, and 1.9 g of acrylic acid to prepare a modified monomer. Mix the basic monomer and the modified monomer evenly to form a mixed solution.

[0077] 0.2 g of ethyl acetate and 0.1 g of benzoyl peroxide were mixed to prepare an organic solution of the initiator. And 100g of ethyl acetate was used as the organic solvent.

[0078] Add 1 / 3 of the mixed solution, 1 / 3 of the organic solution of the initiator, and all the organic solvents into a four-neck flask equipped with stirring, reflux device, and constant pressure dropping funnel. Raise the temperature to 80°C, and after reacting for 3 hours, add the remaining 2 / 3 of the mixed solution and the remaining 2 / 3 of the organic solution of the initiator dropwise, and control the dropping within 4 hours. After dripping and keeping...

Embodiment 2

[0081] Mix 65 g of n-butyl acrylate, 13 g of isooctyl acrylate, 3 g of stearyl methacrylate, and 8 g of methyl methacrylate to prepare basic monomers. Mix 2 g of silicone with double bonds at both ends with a molecular weight of 5000, and 4 g of acrylic acid to prepare a modified monomer. Mix the basic monomer and the modified monomer evenly to form a mixed solution.

[0082] Mix 2 g of ethyl acetate and 1 g of benzoyl peroxide to prepare an organic solution of the initiator. 100 g of ethyl acetate and 50 g of butyl acetate were mixed as a mixed solvent.

[0083]Add 1 / 3 of the mixed solution, 1 / 3 of the organic solution of the initiator, and all the mixed solvent into a four-neck flask equipped with a stirring, reflux device, and constant pressure dropping funnel. Raise the temperature to 85°C, and after reacting for 3 hours, add the remaining 2 / 3 of the mixed solution and the remaining 2 / 3 of the organic solution of the initiator dropwise, and control the dropping within 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com