Polyimide film and preparation methods thereof

A technology of polyimide film and polyimide resin, which is applied in the field of polyimide, can solve the problems of colorless and transparent polyimide film popularization and use, poor film mechanical properties, and difficulty in dianhydride synthesis. Achieve high visible light transmittance, low curing temperature, excellent thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Correspondingly, the invention provides a kind of preparation method of polyimide film, comprises the following steps:

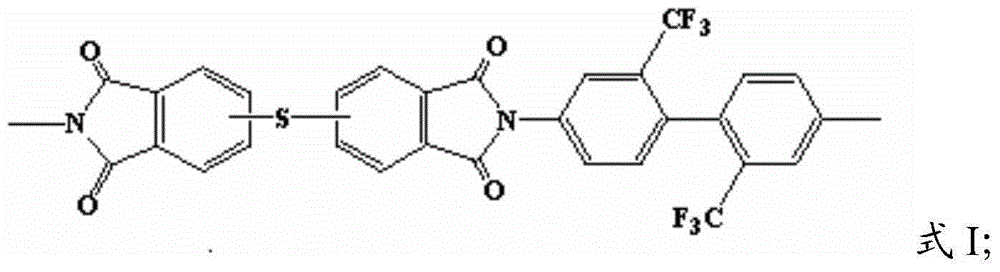

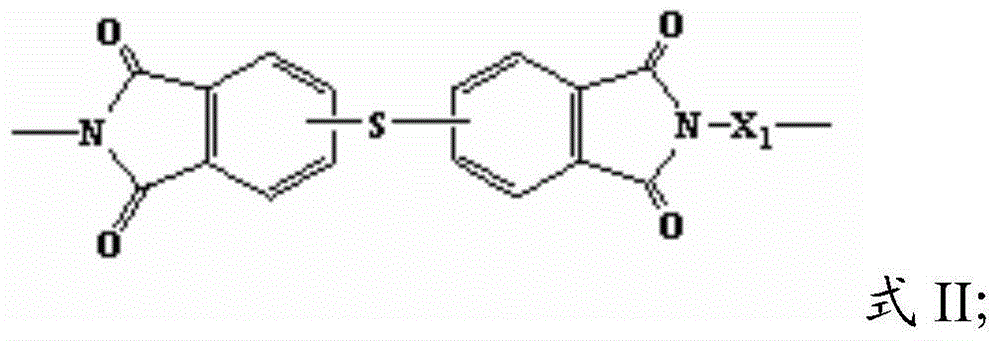

[0064] 1A) reacting diphenyl sulfide dianhydride and para-aromatic diamine in the first organic solvent to obtain a polyimide solution; the diphenyl sulfide dianhydride includes 3,4,3',4'- One or more of diphenyl sulfide dianhydride, 2,3,2',3'-diphenyl sulfide dianhydride, 2,3,3',4'-diphenyl sulfide dianhydride, said Aromatic diamines include 2,2'-bistrifluoromethyl-4,4'diaminobiphenyl;

[0065] 1B) Precipitating the polyimide solution to obtain a polyimide resin;

[0066] 1C) mixing the polyimide resin, a release agent and a second organic solvent to obtain a polyimide resin solution;

[0067] 1D) Casting the polyimide resin solution to form a film to obtain a polyimide film.

[0068] In this application, diphenyl sulfide dianhydride is used as a dianhydride monomer, and 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl is used as a diamine monomer to ...

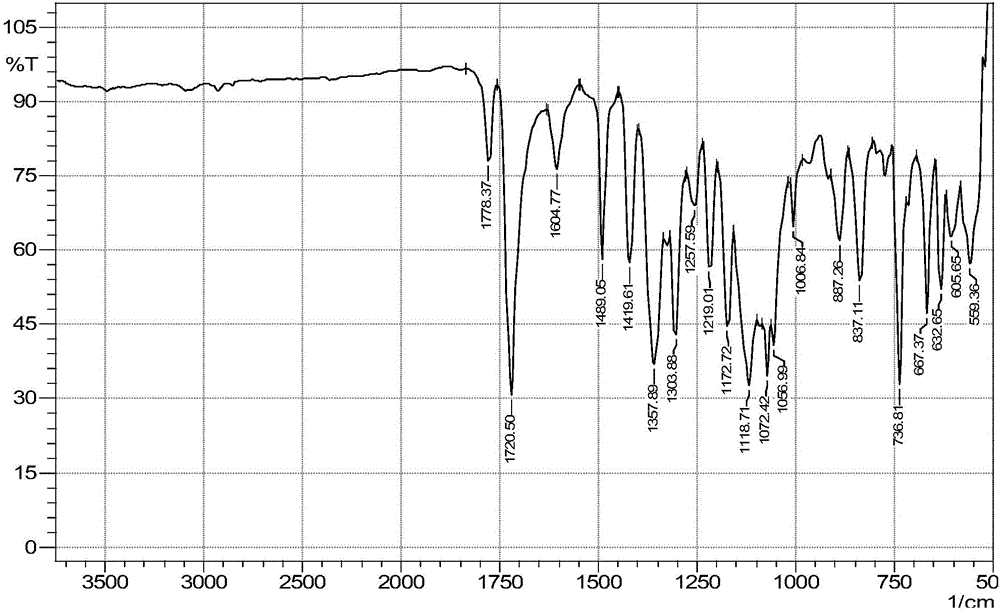

Embodiment 1

[0120] In the presence of nitrogen and stirring, 10.4119g of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl was dissolved in 105g of phenol, and after complete dissolution, 10.6076g of 3,4 , 3',4'-diphenyl sulfide dianhydride, heated to 180 ° C for reaction, stirred for 30 hours to generate a polyimide solution.

[0121] The polyimide solution was gradually added into the ethanol under high-speed stirring to obtain a white silk flocculent polyimide resin.

[0122] The white silk flocculent polyimide resin was washed, and then dried at 100° C. for 8 hours to obtain 17.61 g of dried white silk flocculent polyimide resin. 100 g of dimethylacetamide was used to dissolve 17.61 g of the dried white flocculent polyimide resin, and then 0.06 mL of triphenyl phosphite was added with a pipette, and stirred for 8 hours to obtain a polyimide resin solution.

[0123] After the obtained polyimide resin solution was filtered and vacuum defoamed for 3 hours, it was cast on a glass plate to for...

Embodiment 2

[0128] In the presence of nitrogen and stirring, 10.4728g of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl was dissolved with 120g of m-cresol, and after it was completely dissolved, 1.0670g of 2 ,3,2',3'-diphenyl sulfide dianhydride, 5.3348g 3,4,3',4'-diphenyl sulfide dianhydride and 4.2679g 2,3,3',4'-diphenyl sulfide Dianhydride, heated to 120°C for reaction, stirred for 30 hours to generate polyimide glue.

[0129] The obtained polyimide solution was gradually added into ethanol under high-speed stirring to obtain a white silk flocculent polyimide resin.

[0130] The white silk floc polyimide resin was washed, and then dried at 100° C. for 8 hours to obtain 17 g of dried white silk floc polyimide resin. Dissolve 17 g of the dried white flocculent polyimide resin with 97 g of dimethylacetamide, then add 0.07 mL of triphenyl phosphite with a pipette, and stir for 8 hours to obtain a polyimide resin solution.

[0131] After the obtained polyimide resin solution was filtered a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com