visible light sensor

A visible light and sensor technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of weak anti-infrared interference ability, achieve good linearity, simple peripheral circuits, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

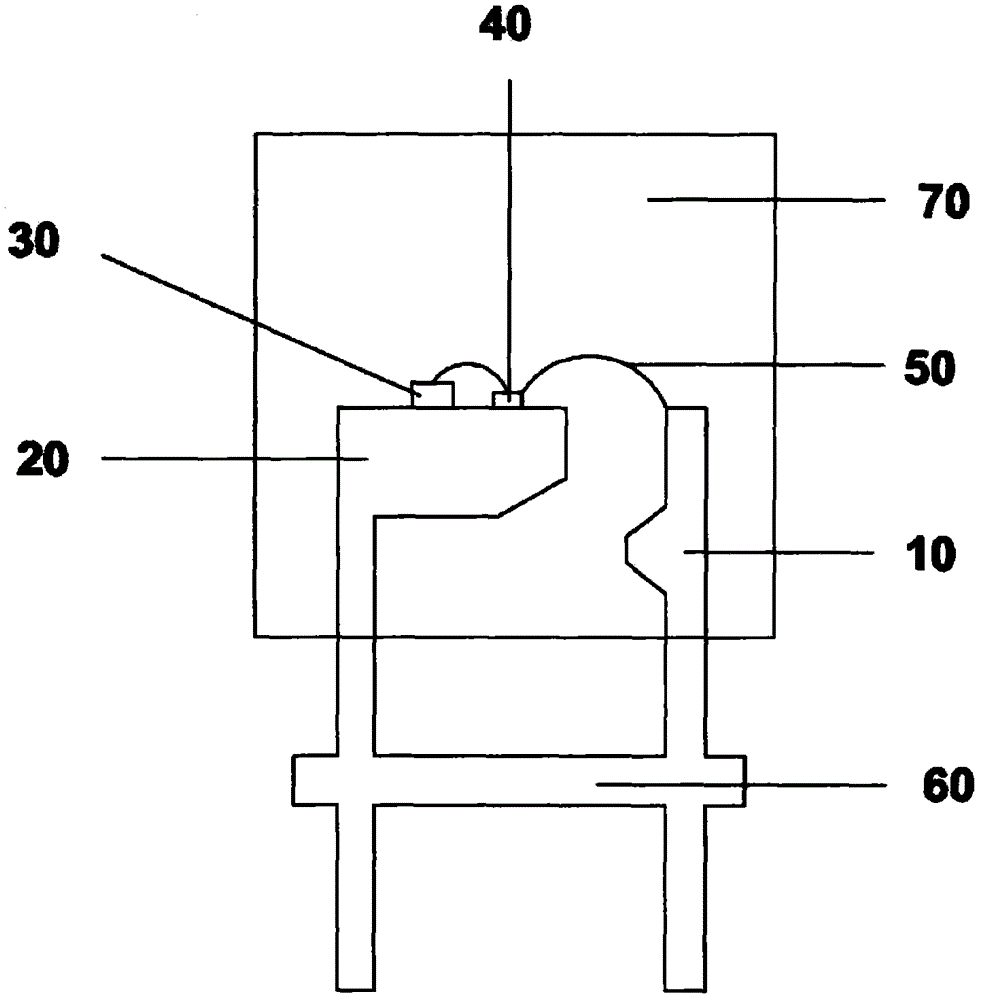

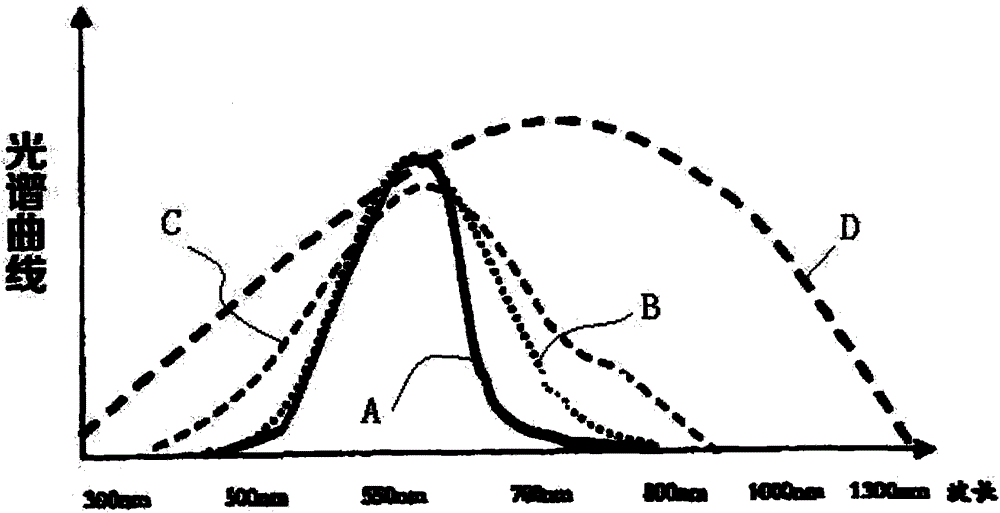

[0031] The following will be combined with figure 1 And attached figure 2 The present invention is further described, but it should not be used to limit the protection scope of the present invention.

[0032] The anti-infrared photosensitive receiving device packaging material of the present invention includes epoxy resin, curing agent, metal oxide and colorant; the epoxy resin is bisphenol A type epoxy resin, and the curing agent is methylhexahydro Phthalic anhydride, the metal oxide is WO , and the toner is yellow epoxy resin toner or orange epoxy toner. Based on the number of parts of bisphenol A epoxy resin: the number of parts of the bisphenol A epoxy resin is 80 to 95 parts; the number of parts of the methyl hexahydrophthalic anhydride is 90 to 99 parts ; The number of copies of WO3 is 0-20 parts; the number of copies of the colorant is 0-20 parts.

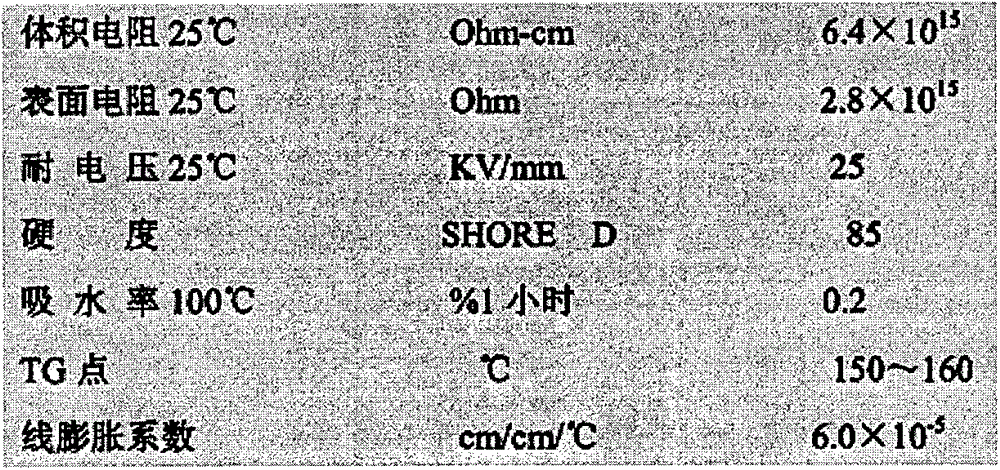

[0033] The specific technical indicators of the bisphenol A type epoxy resin, methyl hexahydrophthalic anhydride, WO3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com