Pretreatment method of ramie degumming wastewater and device adopting same

A pretreatment and degumming technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as coagulant and flocculant secondary pollution, and save manpower , high reliability, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of pretreatment method of ramie degumming waste water, comprises the following steps:

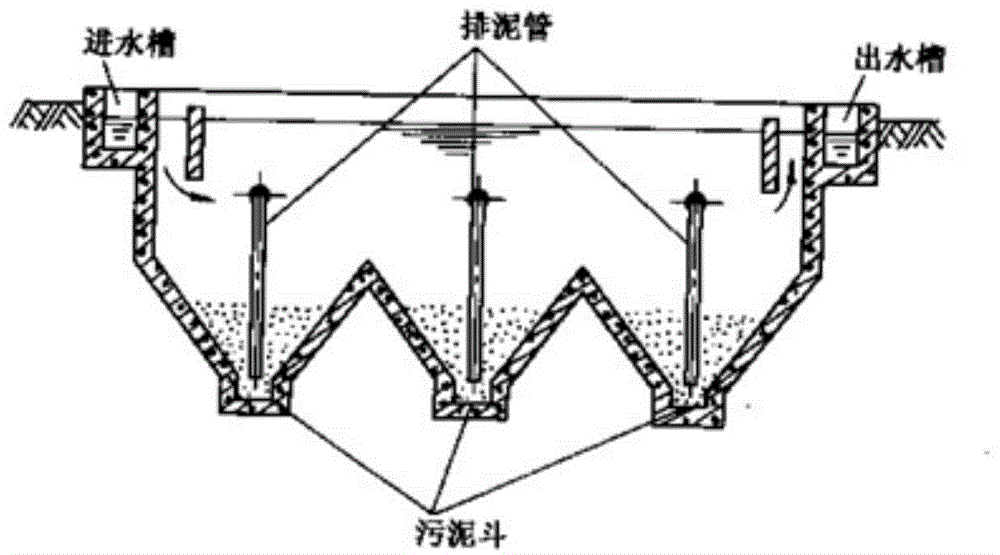

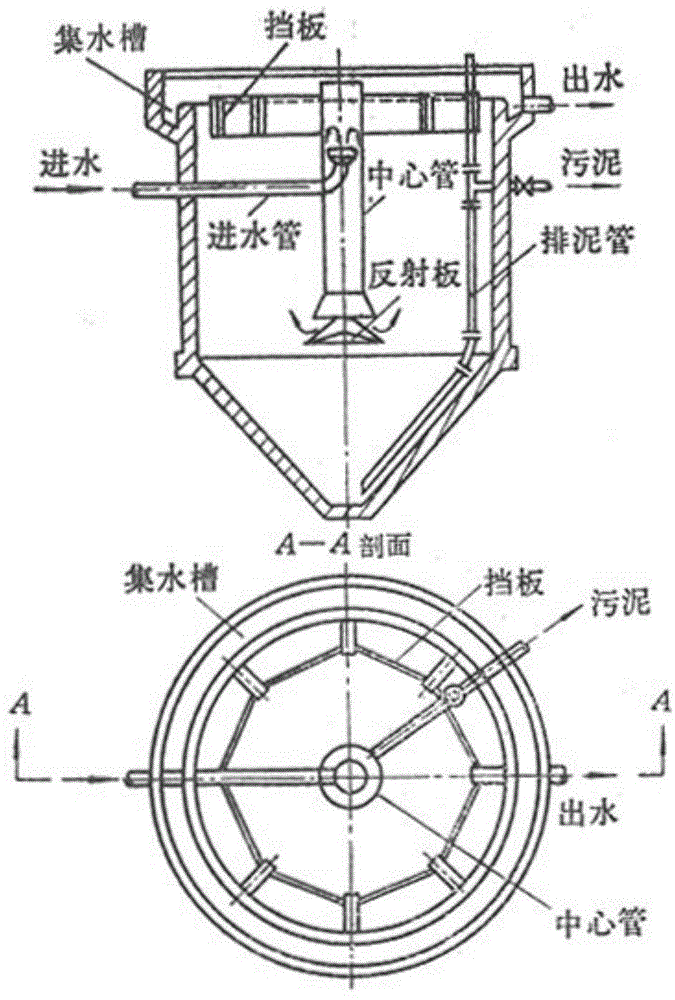

[0055] The alkaline degumming black liquor and acidic waste liquor produced in the chemical degumming method to remove the ramie colloid are passed into the pickling tank and the degumming tank respectively, then the alkaline degumming black liquor and the acidic waste liquor are mixed in the first mixing tank, and the acidic waste liquor is mixed with sulfuric acid After adjusting the pH to 2, the liquid is passed into the separation device. The separation device adopts the horizontal flow sedimentation method to remove the flocs and then passes the clear liquid into the second mixing tank. At the same time, the alkaline cleaning wastewater in the degumming tank is passed into the In the second mixing tank, after mixing the liquid in the second mixing tank and adjusting the pH to 6, the subsequent biological treatment can be carried out.

Embodiment 2

[0057] A kind of pretreatment method of ramie degumming waste water, comprises the following steps:

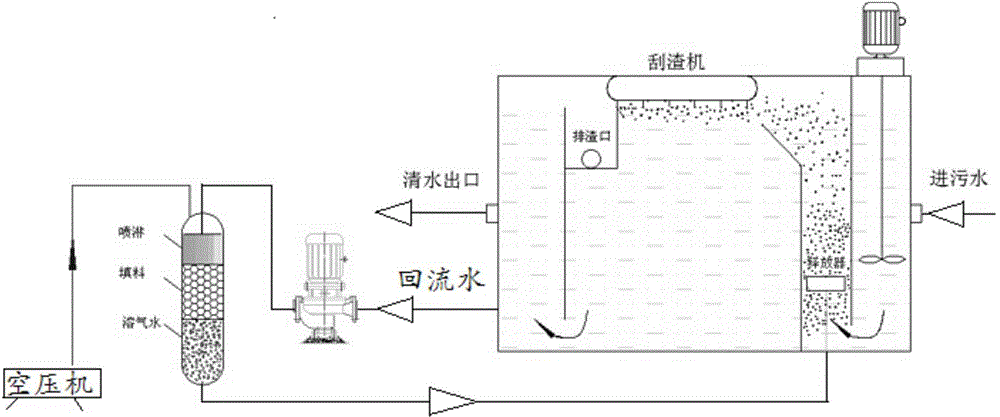

[0058] The alkaline degumming black liquor and acidic waste liquor produced in the chemical degumming method to remove the ramie colloid are passed into the pickling tank and the degumming tank respectively, then the alkaline degumming black liquor and the acidic waste liquor are mixed in the first mixing tank, and then mixed with hydrochloric acid After adjusting the pH to 3, the liquid is passed into the separation device. The separation device uses the air flotation method to remove the flocs and then passes the clear liquid into the second mixing tank. At the same time, the alkaline cleaning wastewater in the degumming tank is passed into the second mixing tank. The second mixing tank, after mixing the liquid in the second mixing tank and adjusting the pH to 7, the subsequent biological treatment can be carried out.

Embodiment 3

[0060] A kind of pretreatment method of ramie degumming waste water, comprises the following steps:

[0061] The alkaline degumming black liquor and acidic waste liquor produced in the chemical degumming method to remove the ramie colloid are passed into the pickling tank and the degumming tank respectively, then the alkaline degumming black liquor and the acidic waste liquor are mixed in the first mixing tank, and then mixed with hydrochloric acid After adjusting the pH to 4, the liquid is passed into the separation device. The separation device uses sand filtration to remove flocs and then passes the clear liquid into the second mixing tank. At the same time, the alkaline cleaning wastewater in the degumming tank is passed into the second mixing tank. In the mixing tank, after mixing the liquid in the second mixing tank and adjusting the pH to 8, the subsequent biological treatment can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com