Synthesis method for hydrocalumites and hydrocalumites based PVC complex heat stabilizer

A composite heat stabilizer, hydrocalumite technology, applied in chemical instruments and methods, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve problems such as expensive organic tin, environmental pollution, health toxicity, etc., to achieve cost Low cost, easy manufacture, and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 36 grams of CaCl 2 2H 2 O (0.24mol), 32 grams of AlCl 3 ·6H 2 O (0.12mol), after mixing, add 260ml of water to make a mixed salt solution; weigh 13 grams of Na 2 CO 3 (0.12mol), add 130ml of water; 28 grams of NaOH (0.7mol), add 130ml of water, and dissolve them respectively to form a mixed alkali solution. The two solutions were dropped into the reaction flask with electric stirring and oil bath heating at the same speed. The addition was completed within 30 minutes, the reaction temperature was controlled to be 75±2°C, the pH of the mixed solution was controlled to be 10-11, stirred for 3 hours, and then the temperature was kept at 75°C for 12 hours of crystallization. Filter and wash the filter cake, wash the water with pH 7-8, dry the filter cake, pulverize and grind to obtain Ca 2+ / Al 3+ =2:1 hydrocalumite powder.

Embodiment 2

[0023] Weigh 36 grams of CaCl 2 2H 2 O (0.24mol), 21 grams of AlCl 3 ·6H 2 O (0.08mol), after mixing, add 260ml of water to make a mixed salt solution; weigh 11 grams of Na 2 CO 3 (0.95mol), add 130ml of water; 24 grams of NaOH (0.7mol), add 130ml of water, and dissolve them respectively to form a mixed alkali solution. The two solutions are dropped into the reaction bottle with electric stirring and oil bath heating at the same speed, and the addition is completed within 30 minutes. The reaction temperature is controlled at 75±2°C, and the pH of the mixed solution is controlled at 10-11. Stir for 3 hours, and then Keep the temperature at 75°C and crystallize for 12 hours. Filter and wash the filter cake, the pH of the washing water is 7-8, dry the filter cake, pulverize and grind to obtain Ca2+ / Al 3+ =3:1 hydrocalumite powder.

Embodiment 3

[0025] Weigh 36 grams of CaCl 2 2H 2 O (0.24mol) was added with 250ml of water to prepare calcium salt solution A; weigh 13 grams of NaAlO 2 (0.06mol) add water 130ml; 8 grams of Na 2 CO 3 (0.075mol) add 70ml of water; 6.5 grams of NaOH (0.16mol) add 50ml of water, mix the latter three solutions to form solution B, drop the two solutions of A and B into the reaction bottle with electric stirring and oil bath heating at the same speed . The addition was completed within 30 minutes, the reaction temperature was controlled at 75±2°C, and the reaction was stirred for 3 hours. Then keep at 75°C and crystallize for 12 hours. Filtration and dehydration, washing the filter cake, washing water with a pH of 7 to 8, drying the filter cake, crushing and grinding to obtain Ca 2+ / Al 3+ =2:1 hydrocalumite powder.

[0026] According to the above method, hydrocalumite with different ratios of Ca / Al can be obtained by changing the amount of calcium salt and aluminum salt.

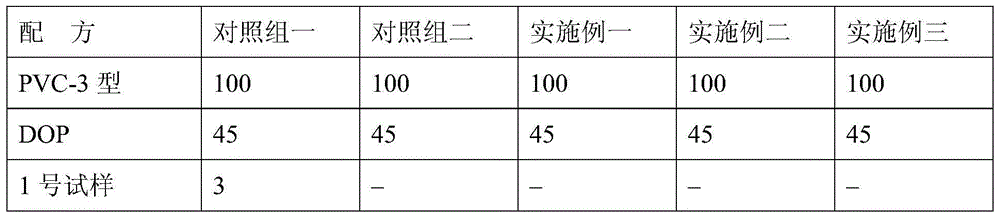

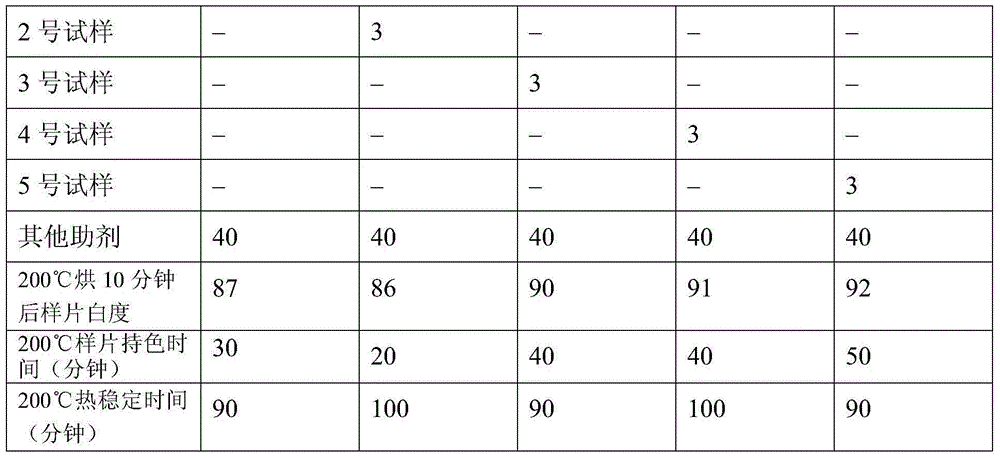

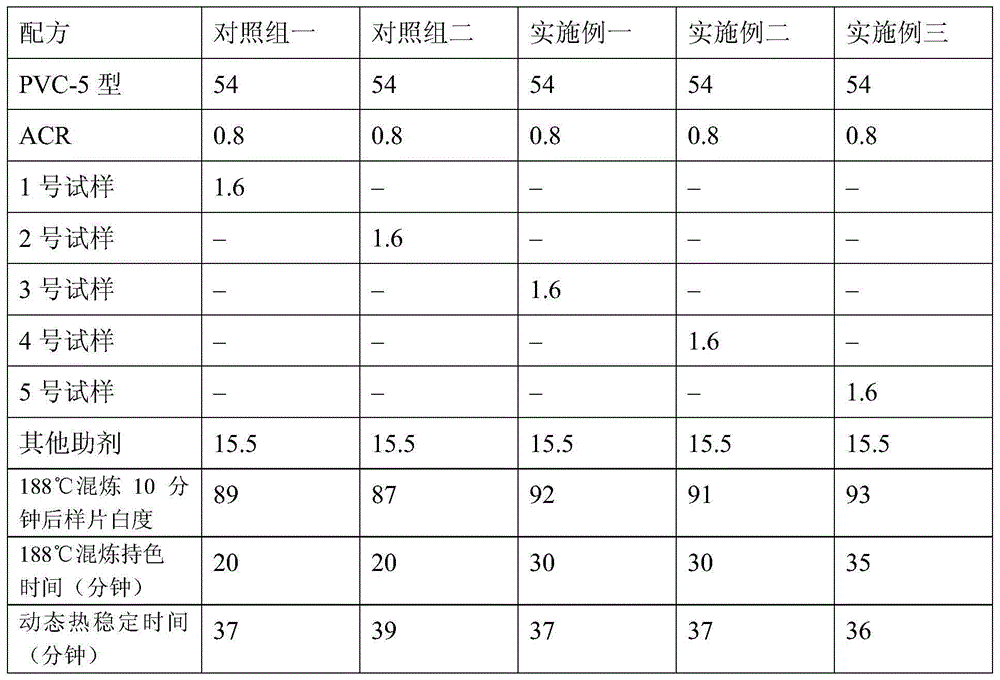

[0027] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com