Single-point and double-point switching type BOPET thin film processing device and method

A processing device and switching technology, applied in the field of plastic film processing, can solve the problems of low production efficiency, single function, obvious adhesion effect, etc., and achieve the effects of large elastic modulus, good transparency, and improved longitudinal tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

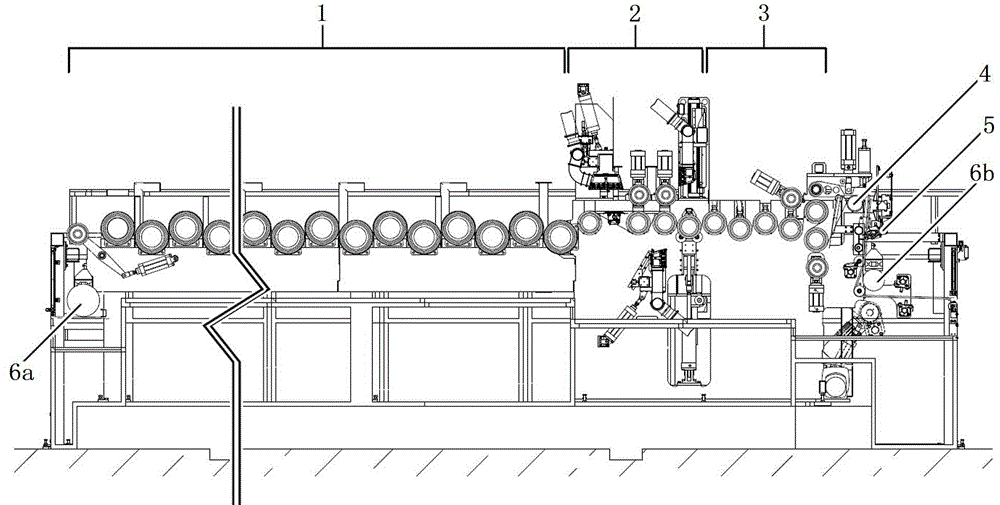

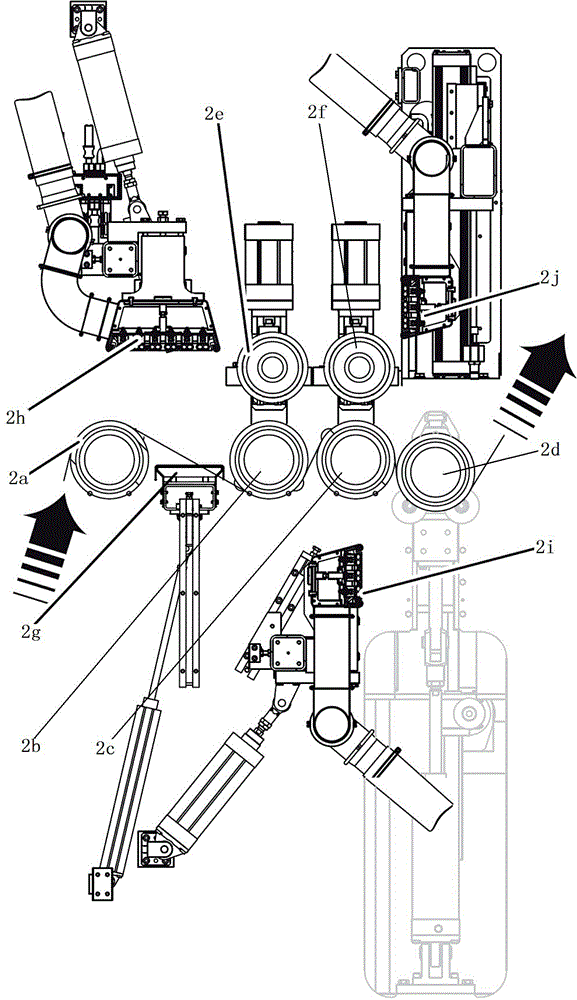

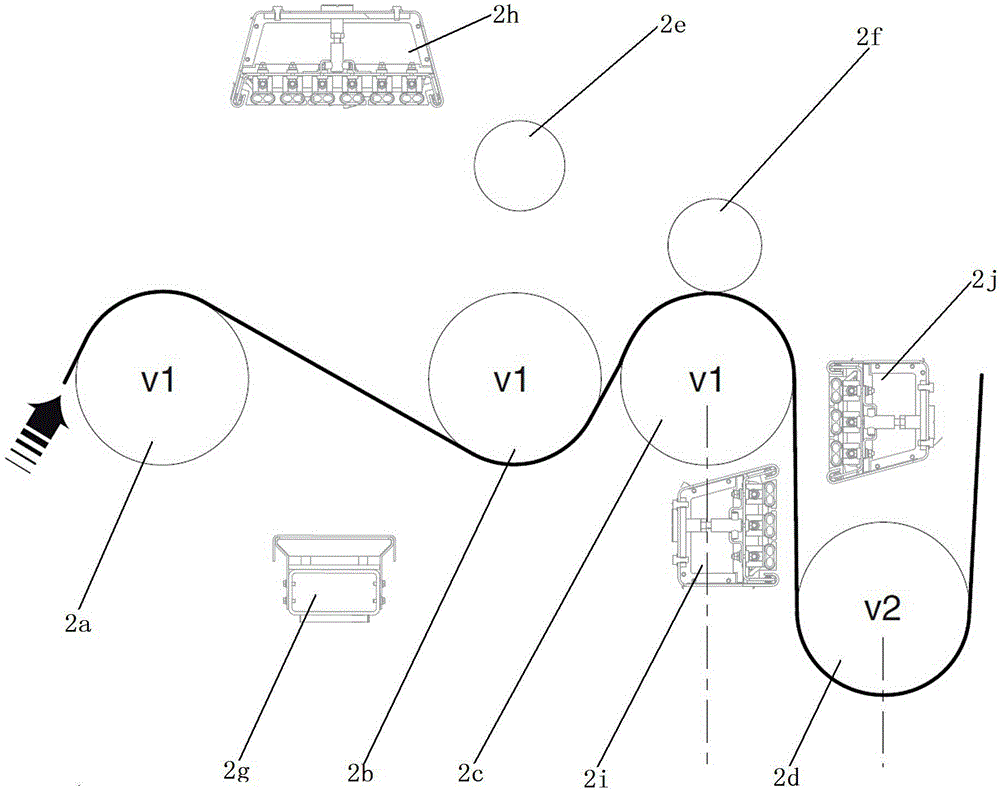

[0023] In this embodiment, a single-double-point switchable BOPET film processing device is combined with figure 1 , including preheating unit 1, stretching unit 2, sizing unit 3, emergency stop floating roller 4, crosscutting unit 5 and tension detection unit (tension detection unit 1 6a and tension detection unit 2 6b), combined figure 2 The preheating unit 1 is used to heat the base film to the stretching temperature. It is composed of a cylinder one 1a, a pressure roller 1b and a preheating roller 1c. A tension detection unit 6a is arranged on the front and bottom of the cylinder one 1a. The cylinder one 1a drives the pressure Roller one 1b is parallel to the preheating roller 1c, the preheating roller 1c is driven by a motor, and the preheating roller 1c is heated by pressurized water; image 3 The stretching unit 2 includes a stretching roll 1 2a, a stretching roll 2 2b, a stretching roll 3 2c, a stretching roll 4 2d, a pressing roll 2e, a pressing roll 3 2f, a reflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com