Device and method for shocking and strengthening thin wall part edges through lasers

A technology of laser shock strengthening and thin-walled parts, which is applied in the direction of auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven power density of spot overlap and difficulty in obtaining uniform residual compressive stress on the surface of the workpiece, and achieve The effect of low cost, shortened working hours and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

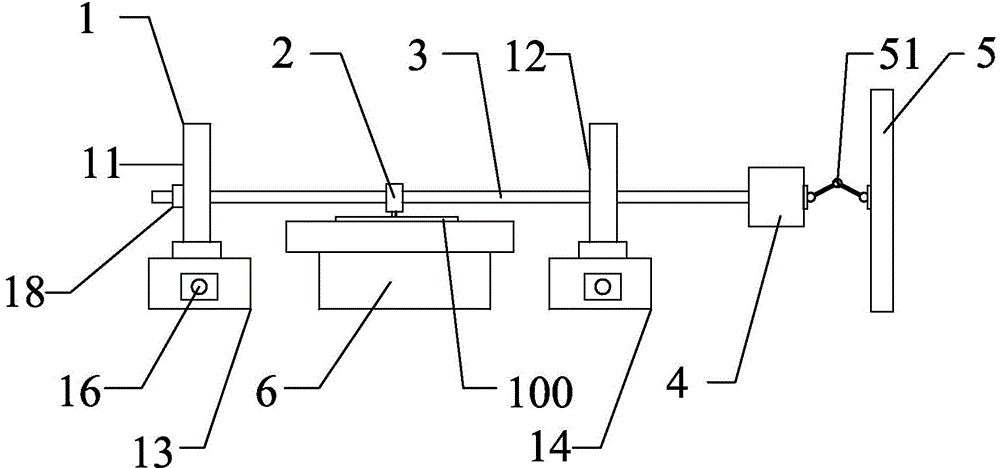

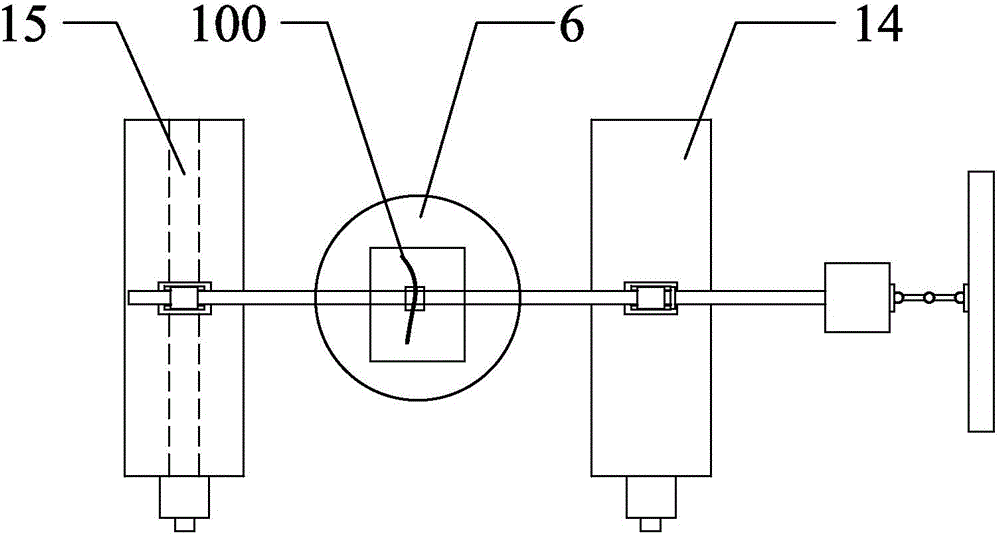

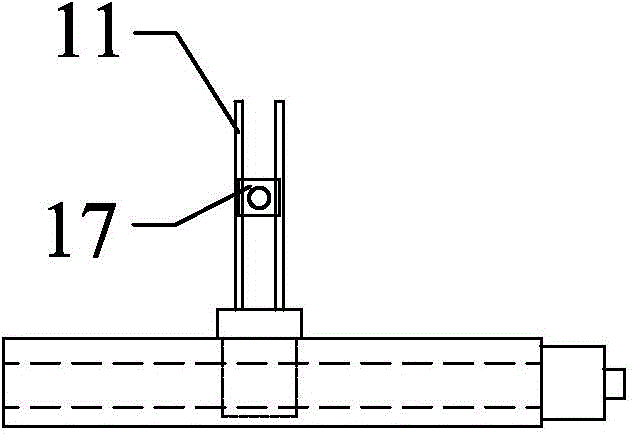

[0030] A device for laser shock hardening the edge of a thin-walled part, including a surface path replication system and a laser shock system. like figure 1 , 2 As shown, the surface path replication system includes a longitudinal support 1, an abutment device 2, a control rod 3, a control box 4, a fixed support 5 and a workbench 6; the longitudinal support 1 includes a longitudinal support I11 and a longitudinal support II12, the The longitudinal support I11 and the longitudinal support II12 are respectively fixed on the horizontal guide rail I13 and the horizontal guide rail II14. The longitudinal support 1 is fixed by connecting the bottom of the longitudinal support 1 to the screw rod 15 arranged in the horizontal guide rail. The motor on one side of the horizontal guide rail 16 drives the screw rod 15 to rotate so as to realize the horizontal movement of the longitudinal support 1. During operation, the motors 16 on the horizontal guide rail I13 and the horizontal guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com