Automatic adjustment structure for flanging sub mold or extending sub mold

An automatic adjustment and edge sub-mold technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting debugging efficiency, time-consuming and laborious, and achieve the effects of convenient use, automatic adjustment, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

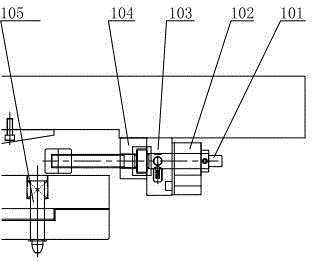

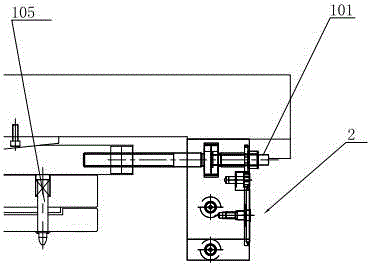

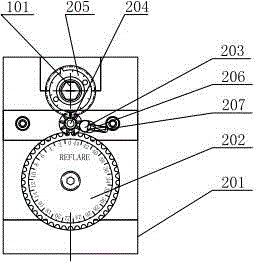

[0024] A self-adjusting structure for flanging sub-moulds or extension sub-moulds, such as Figure 3 to Figure 7 As shown, the automatic adjustment mechanism 2 includes a housing 201, the screw rod 101 runs through the housing 201, and a first oil cylinder cavity 208 and a second oil cylinder cavity 209 are respectively arranged in the housing 201, and are installed in the first oil cylinder cavity 208. The first piston 212, the end of the first piston 212 is hinged to the first top block 211, and the first top block 211 abuts against the first ratchet 210; The end of the second top block 214 is hinged, and the second top block 214 and the second ratchet 213 abut against each other; the first ratchet 210 and the second ratchet 213 are both socketed with the screw 101, and the first moment is also connected to the screw 101. The dial 205 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com