Separating stamping die and separating process for hot-molded steel plates

A stamping die and hot forming technology, applied in the field of separation of hot forming steel plates, can solve the problems of high maintenance frequency, noisy die wear, high cost of laser cutting process, solve large vibration and noise problems, reduce investment and use requirements, The effect of improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

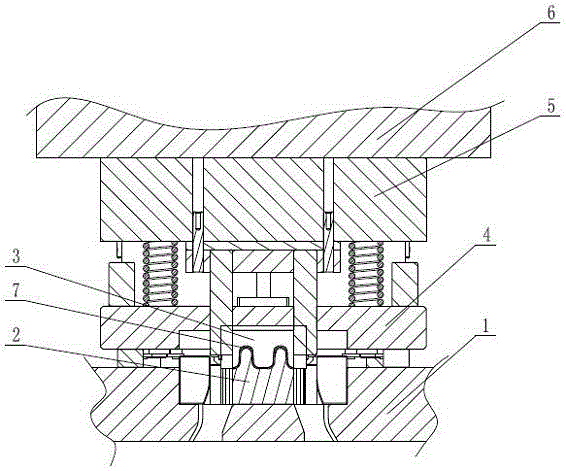

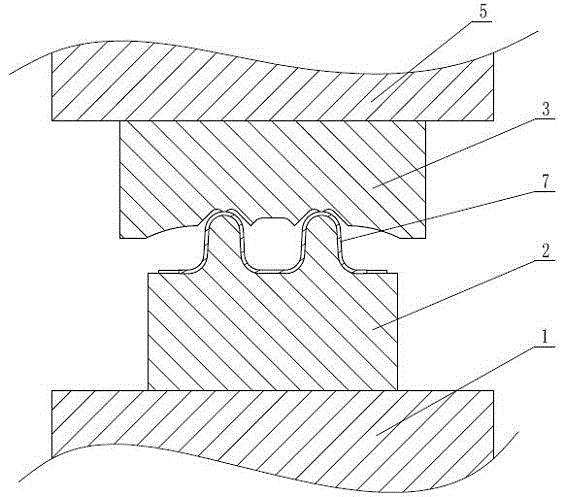

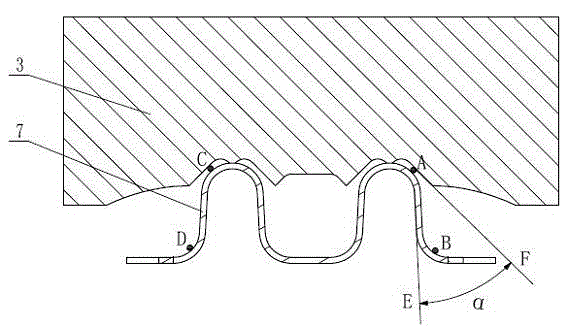

[0055] This embodiment is a preferred embodiment of the present invention. The stamping die for separation uses a hydraulic press with a tonnage of 60 tons, and does not need to be equipped with a cushion. The pressure is adjustable within the range of 0-60 tons, and the speed is 0-450mm / s is adjustable, the stroke of the upper separation insert 3 is 600mm, the stroke of the pressing block 4 is 30mm, and the pressing force is 4 tons. In terms of specific material selection, the upper separation insert 3 and the lower separation insert 2 The cutting edge material can be SKD61, CALDIE, V4E and other high-quality mold steel with a hardness of HRC50 and above, and has toughness, and the hardness of the lower separation insert 2 should not exceed the hardness of the upper separation insert 3. The specific separation process is as follows:

[0056] The first step, workpiece delivery: quickly place the workpiece 7 on the lower separation insert 2 within 0.5 seconds;

[0057] The sec...

Embodiment 2

[0063] The stamping die for separation described in this embodiment is a hydraulic press with a tonnage of 60 tons, and there is no need to be equipped with a cushion. The stroke of the block 3 is 600mm, the stroke of the pressing block 4 is 30mm, and the pressing force is 4 tons. In terms of specific material selection, the edge materials of the upper separation insert 3 and the lower separation insert 2 can be SKD61, CALDIE, V4E and other high-quality mold steels with a hardness of HRC50 and above and toughness, and control the hardness of the lower separation insert 2 to not exceed the hardness of the upper separation insert 3. The specific separation process is as follows:

[0064] The first step, workpiece delivery: quickly place the workpiece 7 on the lower separation insert 2 within 0.5 seconds;

[0065] The second step, fast down: the hydraulic press drives the slider 6 down quickly, at a speed of 150mm / s, and the pressing block 4 starts to contact the workpiece 7. In ...

Embodiment 3

[0071] The stamping die for separation described in this embodiment is a hydraulic press with a tonnage of 60 tons, and there is no need to be equipped with a cushion. The stroke of the block 3 is 600mm, the stroke of the pressing block 4 is 30mm, and the pressing force is 4 tons. In terms of specific material selection, the edge materials of the upper separation insert 3 and the lower separation insert 2 can be SKD61, CALDIE, V4E and other high-quality mold steels with a hardness of HRC50 and above and toughness, and control the hardness of the lower separation insert 2 to not exceed the hardness of the upper separation insert 3. The specific separation process is as follows:

[0072] The first step, workpiece delivery: quickly place the workpiece 7 on the lower separation insert 2 within 0.5 seconds;

[0073] The second step, fast down: the hydraulic press drives the slider 6 down quickly, at a speed of 900mm / s, and the pressing block 4 starts to contact the workpiece 7. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com