High-water-absorbing carbon material under low-humidity condition and modification and preparation method thereof

A technology of high water absorption and carbon materials, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low water vapor adsorption capacity, achieve low cost of modification methods, high water adsorption capacity, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

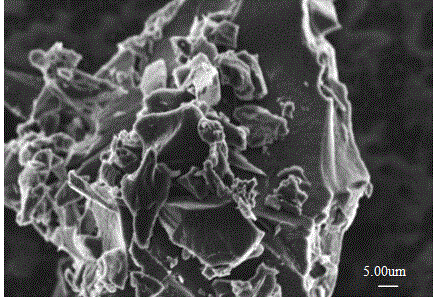

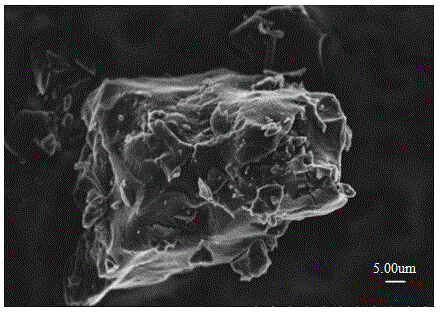

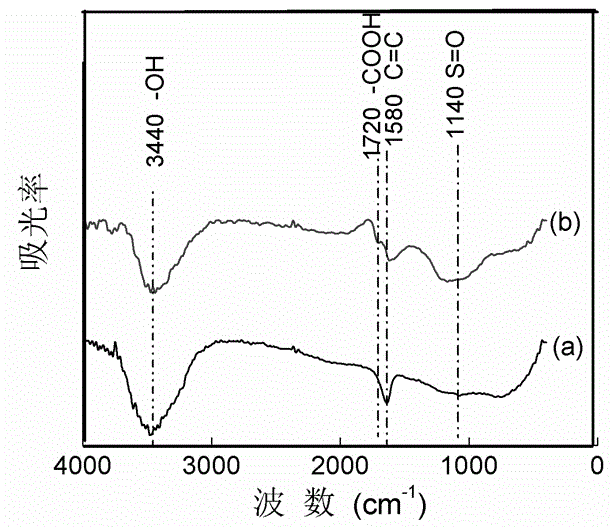

Image

Examples

Embodiment 1

[0026] According to the mass ratio of 0.2:1, add ammonium persulfate into 1M sulfuric acid solution and mix evenly to obtain a persulfuric acid solution; according to the mass ratio of 0.1:1, add the obtained mixed solution into the activated carbon material, stir and mix evenly, and heat at 40°C After 4 hours, the surface modification reaction was carried out; the resulting solution was filtered and dried at 100° C. to prepare a carbon material adsorbent with high water absorption under low humidity conditions. The water adsorption capacity of the prepared modified carbon material adsorbent at 40% humidity is 0.2 g / g.

Embodiment 2

[0028] According to the mass ratio of 1:1, add ammonium persulfate into 2M sulfuric acid solution and mix evenly to obtain a persulfuric acid solution; according to the mass ratio of 0.2:1, add the obtained mixed solution into the activated carbon material, stir and mix evenly, and heat at 60°C After 3 hours, the surface modification reaction was carried out; the resulting solution was filtered and dried at 120° C. to prepare a carbon material adsorbent with high water absorption under low humidity conditions. The water adsorption capacity of the prepared modified carbon material adsorbent at 40% humidity is 0.4 g / g.

Embodiment 3

[0030] According to the mass ratio of 1.5:1, add ammonium persulfate into 3M sulfuric acid solution and mix evenly to obtain a persulfuric acid solution; according to the mass ratio of 0.4:1, add the obtained mixed solution into the activated carbon material, stir and mix evenly, and heat at 60°C After 2 hours, the surface modification reaction was carried out; the resulting solution was filtered and dried at 135° C. to prepare a carbon material adsorbent with high water absorption under low humidity conditions. The water adsorption capacity of the prepared modified carbon material adsorbent at 40% humidity is 0.3 g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com