Novel round brush and high pressure cleaning machine with same

A technology of high-pressure cleaners and round-haired brushes, applied in the fields of new-type round-haired brushes and high-pressure cleaners including them, auxiliary parts of new cleaning equipment and cleaning equipment including them, which can solve the problem of car body surface paint damage and reduce high pressure Water potential energy, reducing the scouring effect and other issues, to achieve the effect of avoiding the shedding of bristles, prolonging the service life and improving the scouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

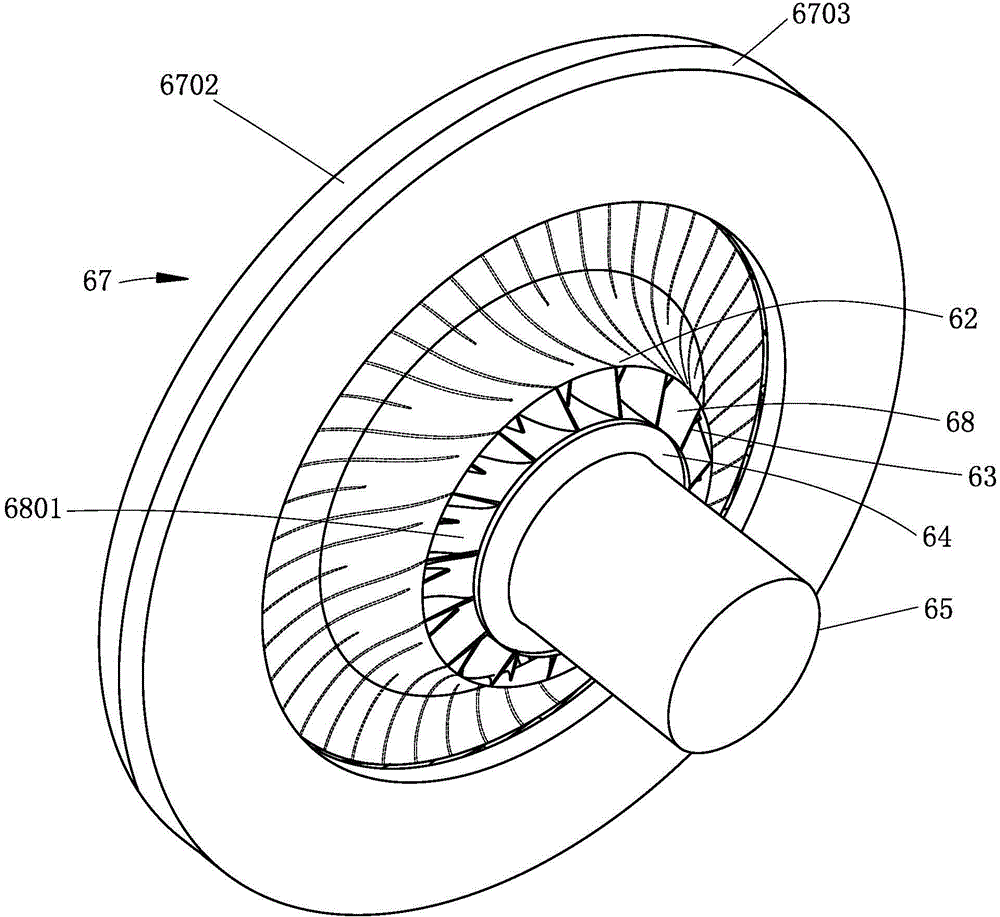

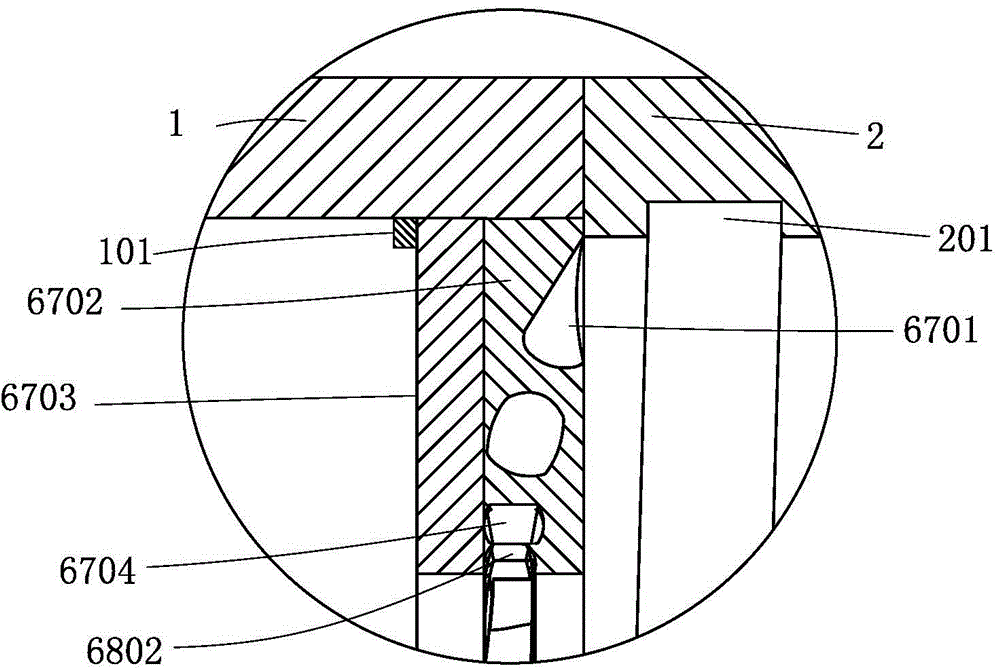

[0032] Such as figure 1 , figure 2 with image 3 Commonly shown, the present invention provides a round brush for high-pressure cleaners. The round brush for high-pressure cleaners mainly includes the upper body 1 of the nozzle and the lower body 2 of the nozzle fixedly installed together, the upper body 1 of the nozzle and the lower body 2 of the nozzle. The lower body 2 is usually screwed together. The upper body 1 of the nozzle and the lower body 2 of the nozzle jointly form a blowing cavity 7. The lower body 2 of the nozzle is fixed with a brush plate 3, and the brush pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com