Production method for elymus nutans griseb silage

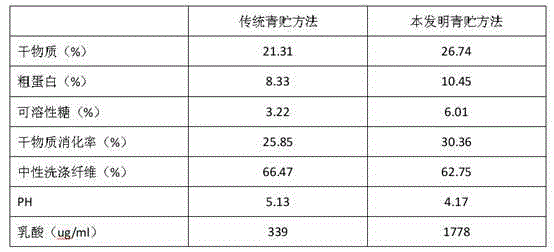

A technology of Elysia chinensis and silage, which is applied to the preservation method of animal feed raw materials, animal feed, animal feed, etc., can solve the problems of loss of nutritional components, unstable products, long silage time, etc., and achieve quality improvement. Reduce the loss of dry matter and increase the effect of lactic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for producing Elymus silage silage, comprising the following steps:

[0021] 1) Preparation of compound silage,

[0022] After 1 kilogram of plant Lactobacillus, 1 kilogram of subtilis live bacteria, 1 kilogram of saccharomyces, 0.5 kilogram of Pediococcus pentosaceae, 0.5 kilogram of cellulase, and 0.5 kilogram of glucose oxidase are mixed uniformly to make the compound silage dry matter, and then Pour 100 grams of compound silage dry matter into 100 liters of clear water and stir evenly, add 800 grams of white granulated sugar, and activate at room temperature for 5 hours to obtain a compound silage liquid, which is set aside;

[0023] 2) Pre-harvest preparation,

[0024] Before silage, remove the residual feed and impurities in the silo, and spread a wide plastic film around and at the bottom of the silo, and then spread 50 cm thick bran on the bottom of the silo, which is conducive to forage fermentation and silage. exhaust;

[0025] 3) Timely harves...

Embodiment 2

[0032] A method for producing Elymus silage silage, comprising the following steps:

[0033] 1) Prepare compound silage liquid:

[0034] After 1 kilogram of plant Lactobacillus, 1.5 kilograms of Bacillus subtilis live bacteria, 2 kilograms of saccharomycetes, 1.5 kilograms of Pediococcus pentosaceae, 1.5 kilograms of cellulase, and 1 kilogram of glucose oxidase are mixed uniformly to make a dry compound silage, and then Pour 200 grams of compound silage dry matter into 100 liters of clear water and stir evenly, then add 1000 grams of white granulated sugar, and activate it at room temperature for 3 hours to obtain a compound silage liquid, which is set aside;

[0035] 2) Preparation before harvest:

[0036] Before silage, remove the residual feed and impurities in the silo, and spread a wide plastic film around and at the bottom of the silo, and then spread 60 cm thick bran on the bottom of the silo, which is conducive to the fermentation of forage and the growth of silag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com