Method for producing a plastic housing

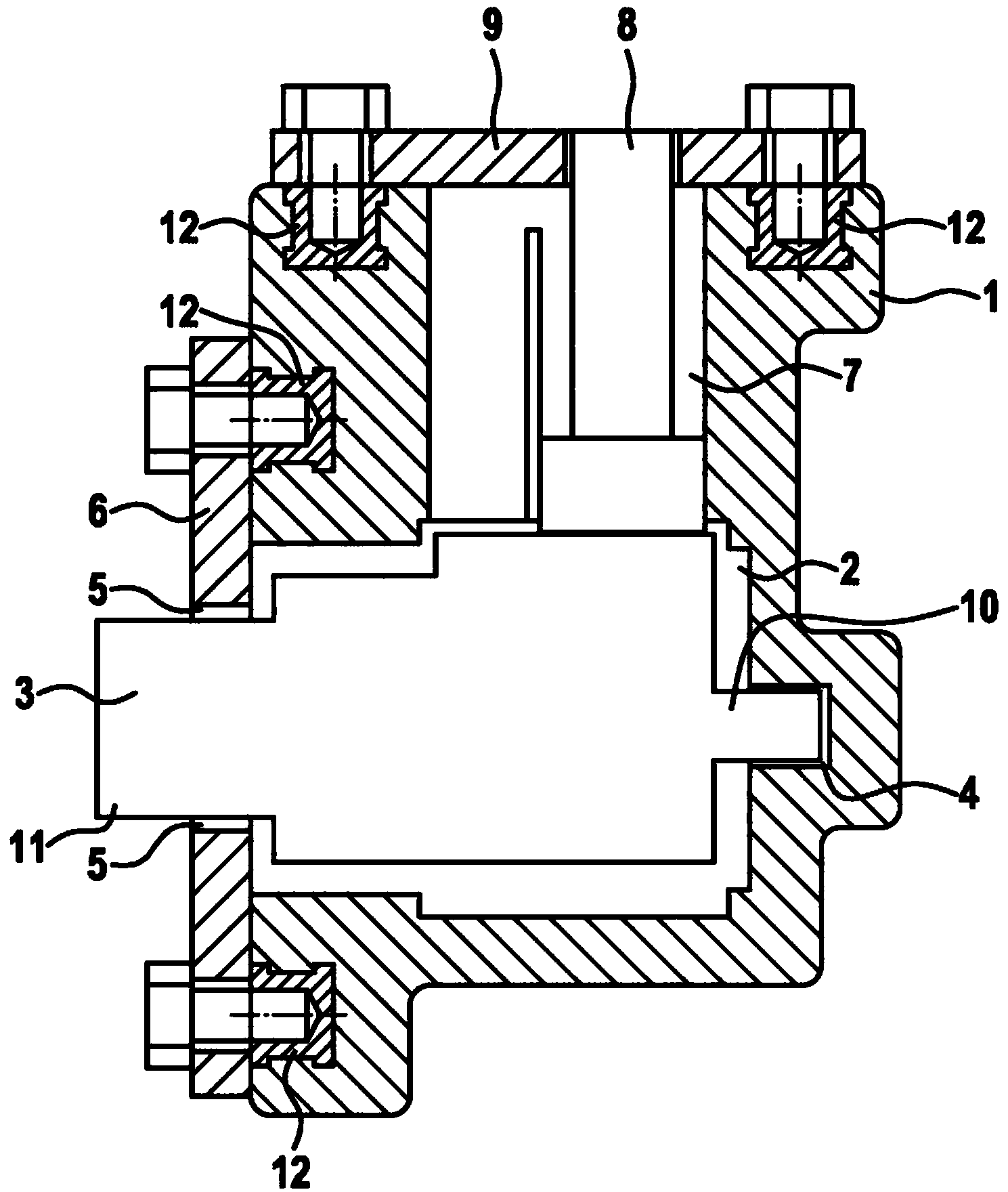

A plastic shell and plastic technology, applied in the field of pump shells and devices implementing the method, can solve the problems of increasing cost, time consumption, sliding block wear and maintenance intervals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Figure 2A A sealing device 100 designed for carrying out the method according to the invention for producing a plastic pump housing is shown, which is designed as a sealing ring and which according to a first embodiment has a closed shape. In a first method step according to the invention, the sealing ring 100 is produced in a casting mold from an injection-moldable polymer, which preferably consists of a perfluoroalkoxy copolymer (PFA). According to an alternative embodiment of the method according to the invention, the sealing ring is produced by extrusion of an elastic semi-finished product.

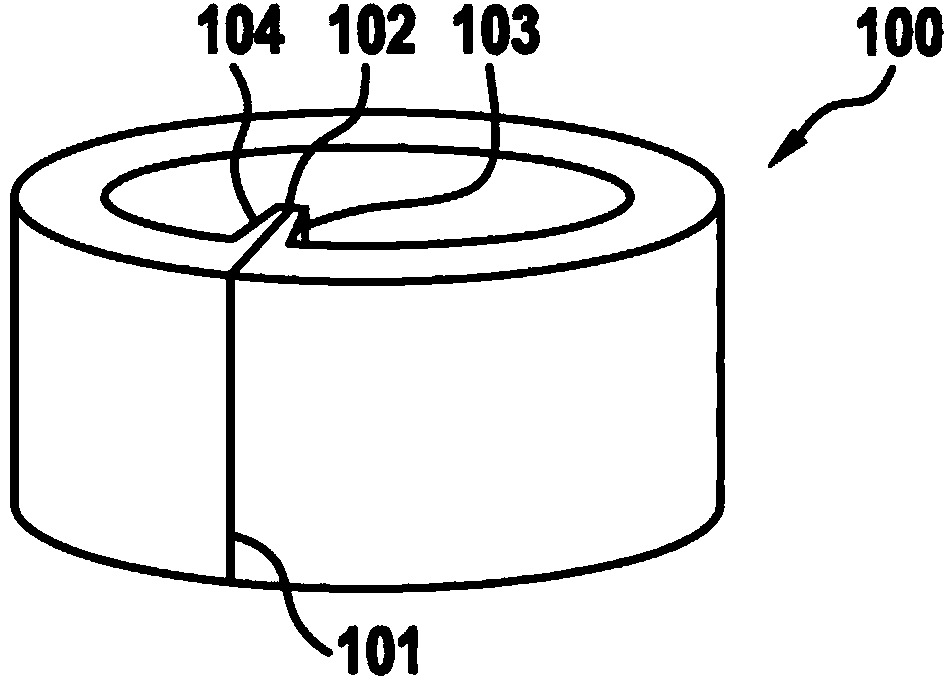

[0015] Figure 2B A second embodiment of a sealing device 100 according to the invention for carrying out the method according to the invention is shown. Here, the sealing device forming the sealing ring 100 has a radially extending parting slit 101 which traverses the sealing ring 100 in the circumferential direction of the sealing ring and not only allows the sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com