A method for processing high-frequency connector jacks

A technology of high-frequency connector and hole processing method, applied in the direction of connection, parts of connecting device, contact parts, etc., can solve the problem of high-frequency performance degradation, improve service life, reduce contact resistance, and ensure continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the drawings and embodiments.

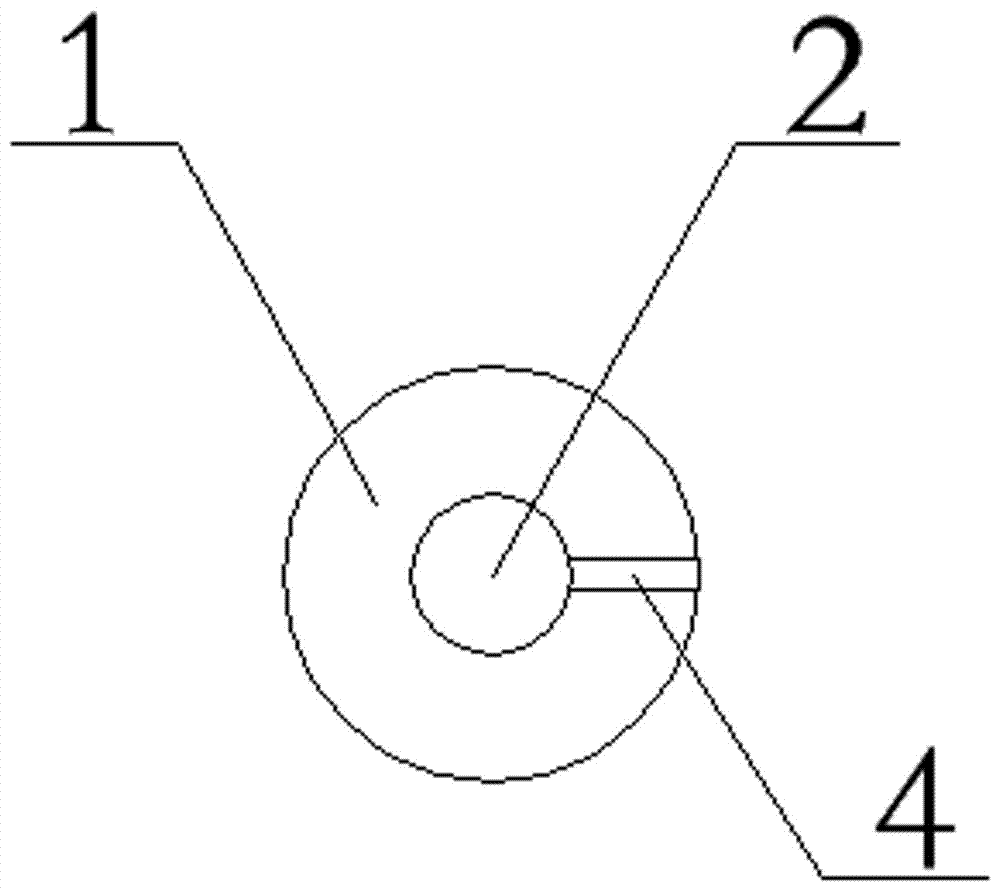

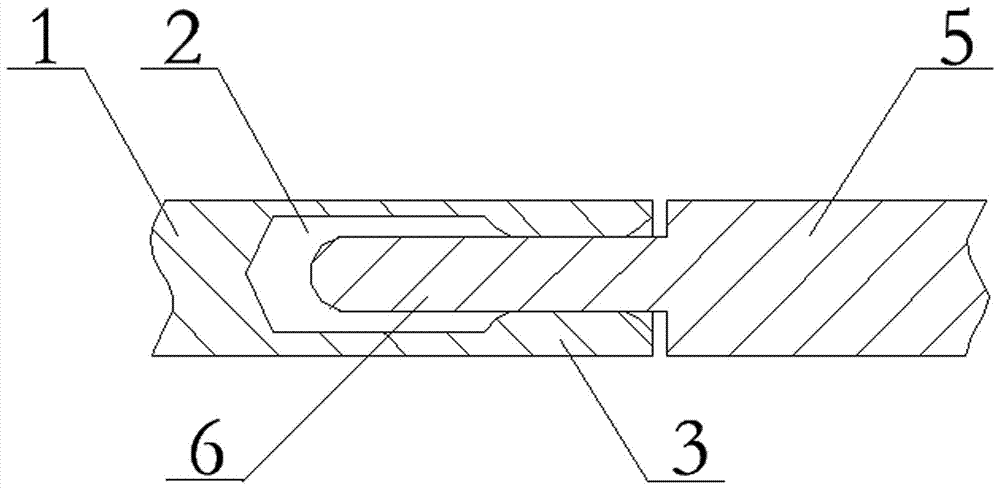

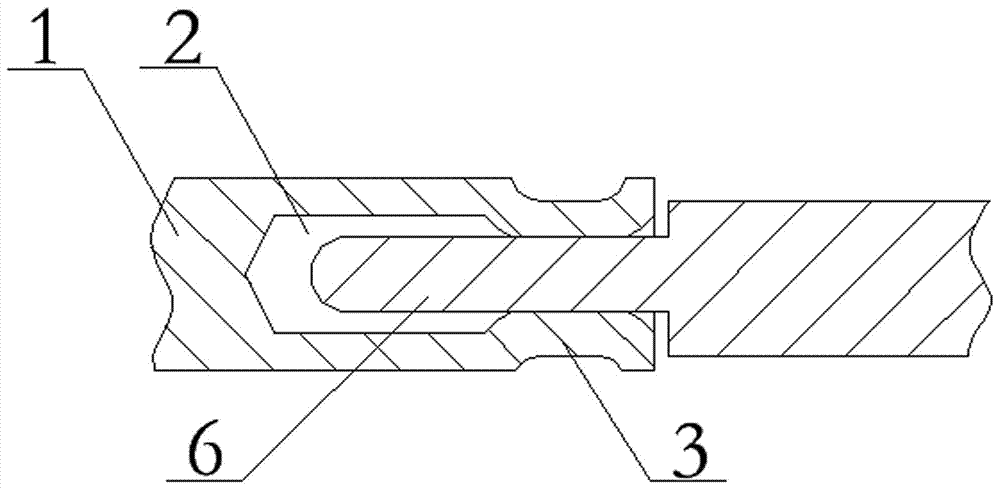

[0015] figure 1 , 2 As shown, a high-frequency connector jack includes a jack seat 1 with a jack 2, and the outer circumference of the jack seat 1 corresponds to the outer circumference of the pin seat 5 of the pin 6 of the jack 2. In the same size, the inside of the hole of the jack 2 is provided with a circle of inserting bosses 3, and the side wall of the jack seat 1 is provided with a slot 4 that penetrates the side wall of the jack seat from the inside to the outside along the direction of the jack 2. The groove depth is less than 85% of the jack depth.

[0016] The processing method of the jack of the present invention includes the following steps:

[0017] a. Determine the rolling diameter of the jack blank according to the final size of the jack plus the size of the mating boss and the machining allowance;

[0018] b. Drill the bottom hole after machining the jack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com