Production control device and method for multi-process equipment on basis of state machines

A production control method and production control technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as difficulty in overall coordination and poor scalability, and achieve enhanced stability and reliability, low cost, The effect of reducing coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

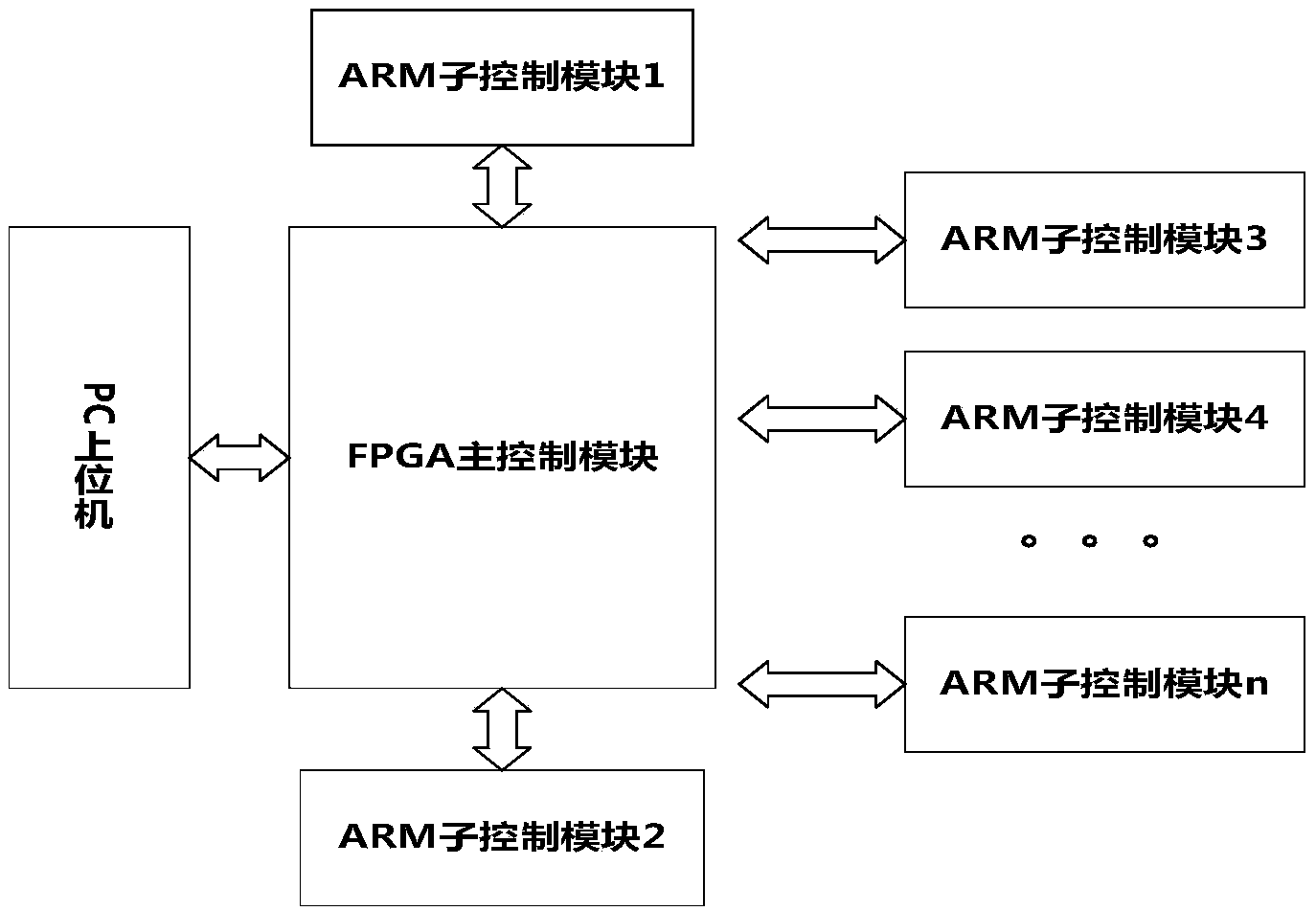

[0056] Such as figure 1 As shown, this embodiment discloses a multi-process equipment production control device based on a state machine, which includes an upper computer PC, an FPGA module connected to the upper computer, and an ARM module used to control the work of each process; The ARM module working in the process as a sub-state machine is connected to the FPGA module as the main state machine, and forms a star topology with the FPGA module. The ARM module contains logic operations for controlling the work of the corresponding process, and each ARM module is separate Independently control the work of one of the processes; the FPGA module is connected with the motor used to transfer the workpiece and the sensor used to detect the position of the workpiece. Among them, the FPGA module in this embodiment is the XC3S500 of the SPARTAN-3E series, and the ARM module is the STM32F103ZET8 of ST Company.

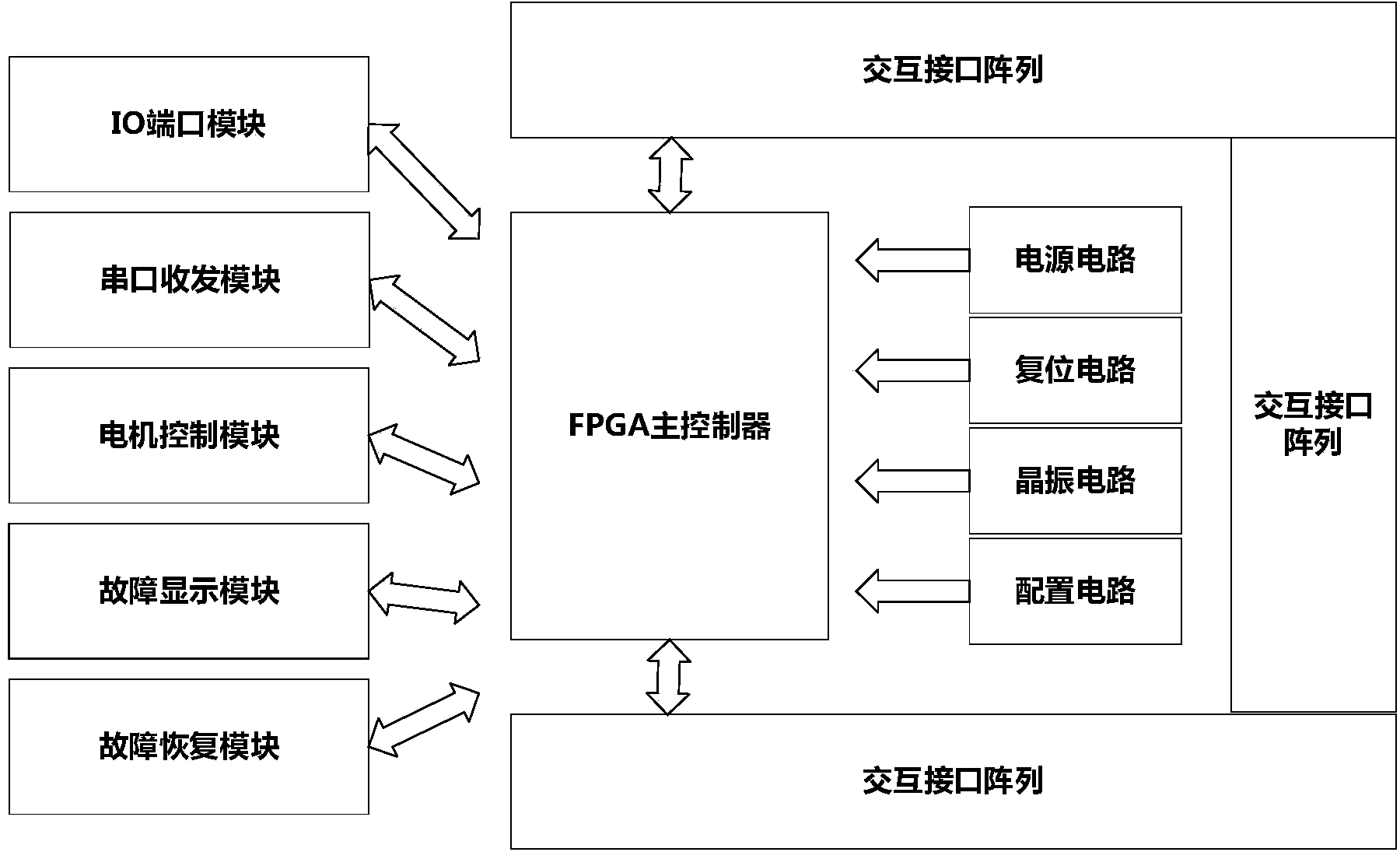

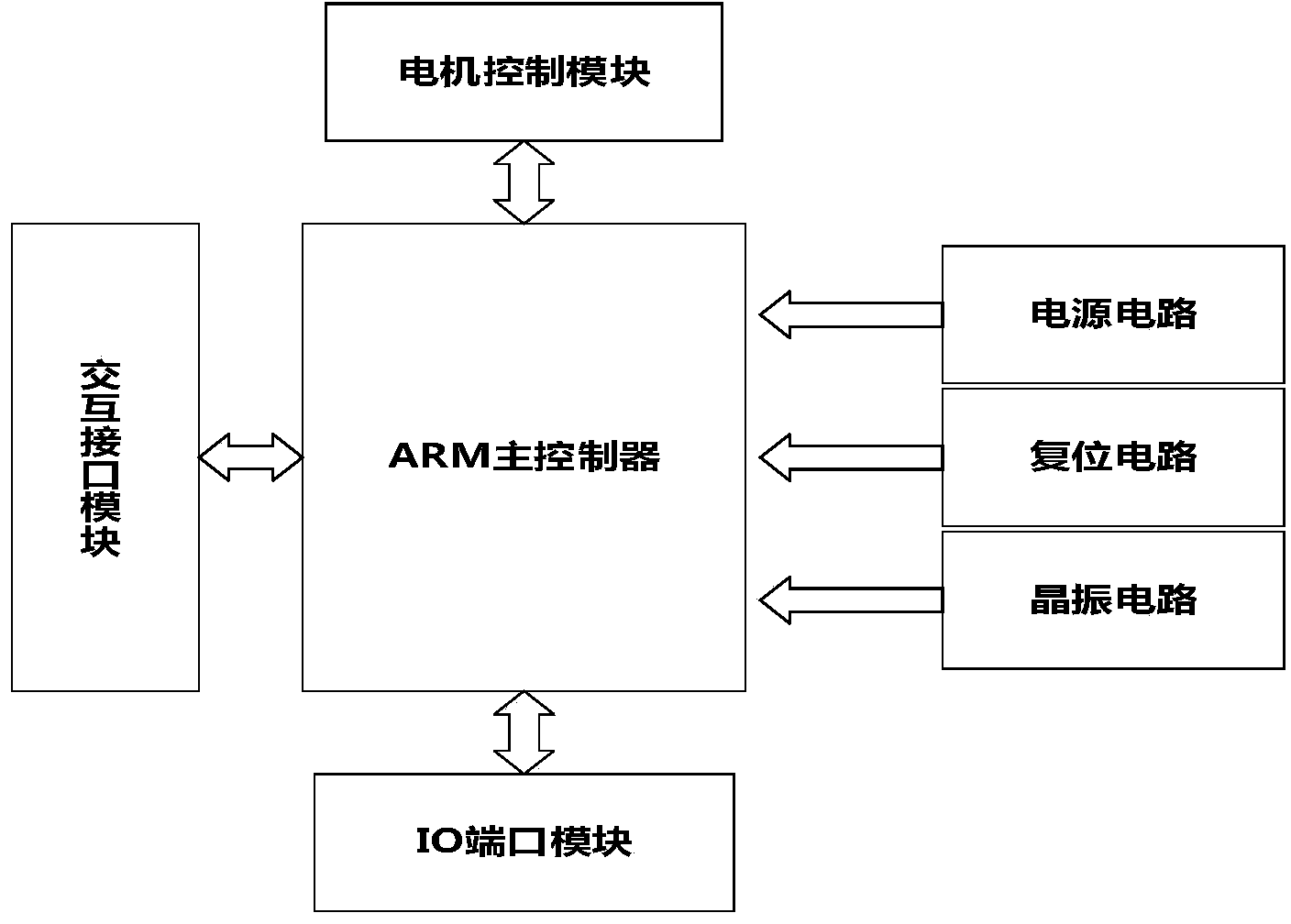

[0057] Such as figure 2 As shown, the FPGA module of this embodiment is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com