Standard fastener detection system based on machine vision

A technology of standard fasteners and detection systems, applied in the field of detection devices, can solve the problems of enterprise work efficiency and labor cost, which are not completely solved, the cost of detection devices is increased, and the thread pitch detection cannot be achieved, and achieves good synchronization and stability. , easy to process and manufacture, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the drawings and embodiments:

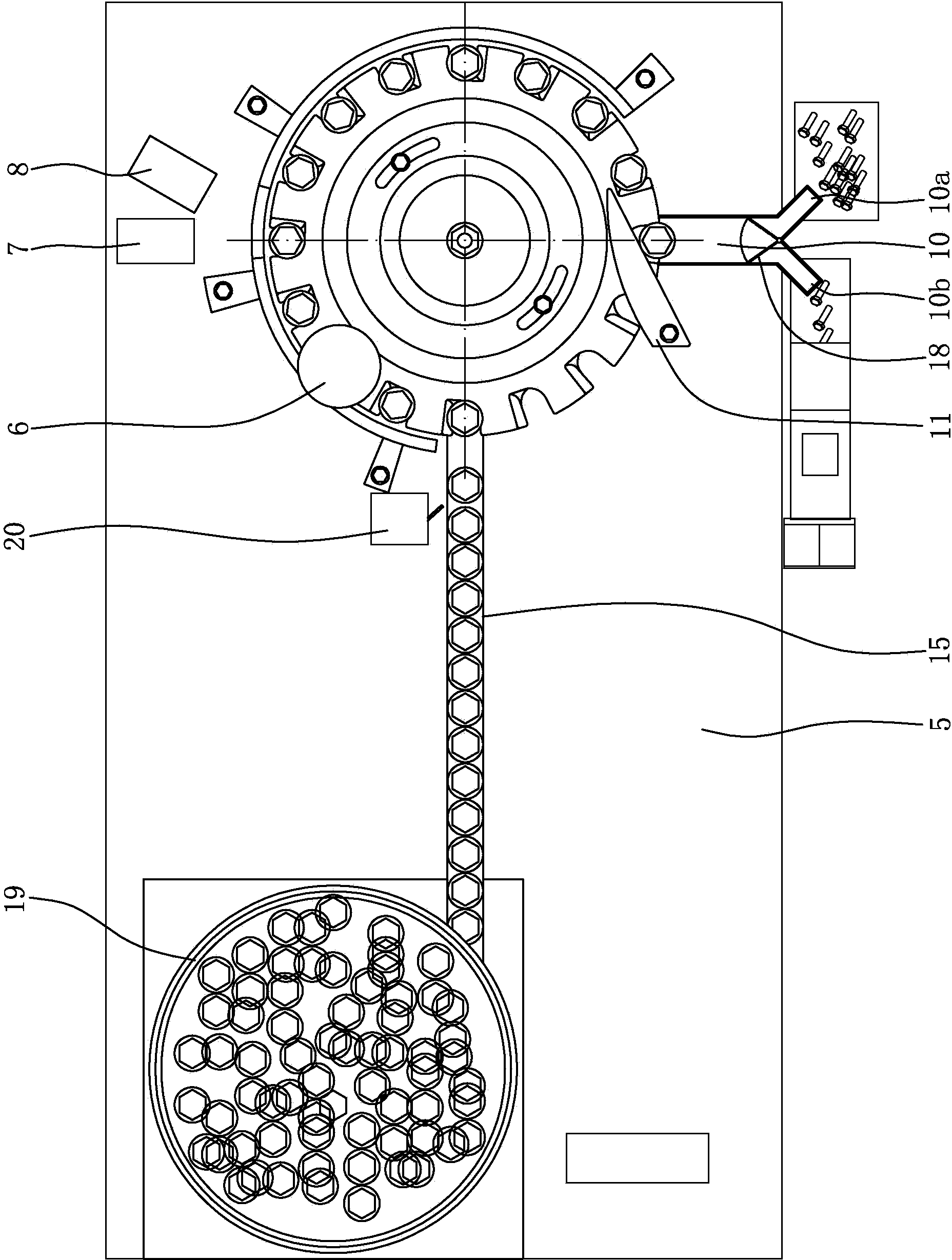

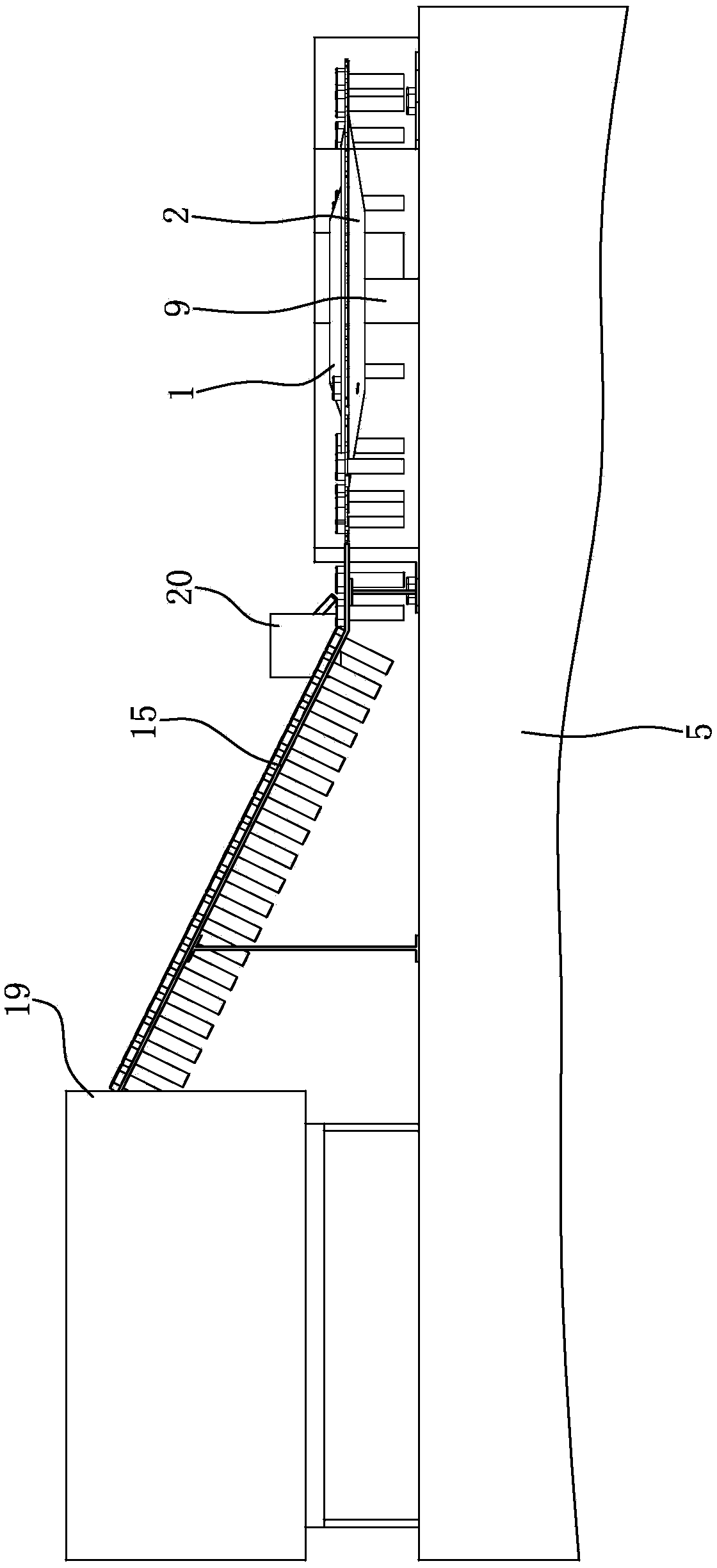

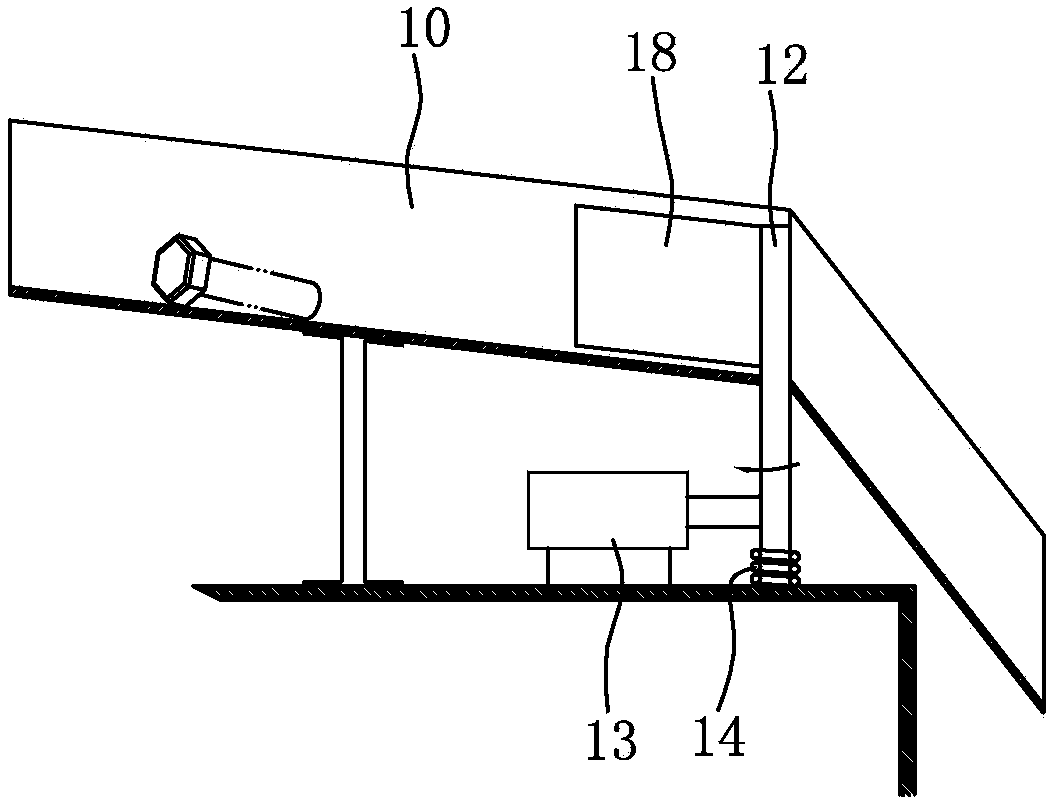

[0040] Such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a vibration plate 19 is installed at one end of the top of the machine table 5, and the vibration plate 19 is driven by a vibration motor. An indexing turntable is arranged at the other end of the top of the machine table 5, and the indexing turntable is arranged on the machine table 5 and is composed of a moving disk 1 and a fixed disk 2. The movable plate 1 and the fixed plate 2 are disc structures with equal diameters, and the movable plate 1 is located directly above the fixed plate 2. The middle part of the top surface of the moving plate 1 is integrally formed with a stepped boss with a small upper part and a large lower part, and the middle part of the bottom surface of the fixed plate 2 is integrally formed with a large upper and a small frustum. The bottom surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com