A square grid plate with vibration isolation properties

A grid plate, square technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problem that vibration isolation and noise reduction cannot be achieved, and the honeycomb structure grid plate does not have vibration isolation and sound insulation performance and other issues to achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

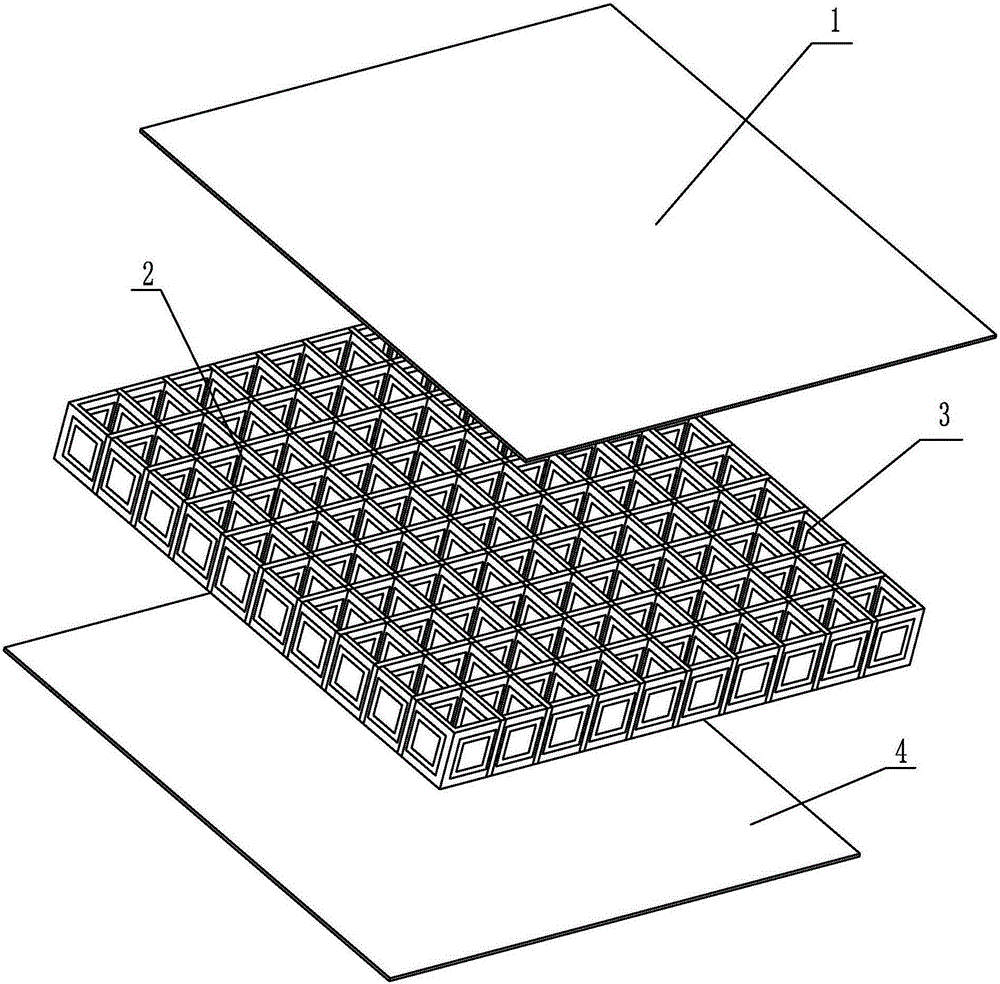

[0009] Specific implementation mode one: combine Figure 1-Figure 3 Explain that a square grid plate with vibration isolation characteristics in this embodiment includes an upper skin 1, a local resonance type phononic crystal vibration isolation component 2 and a lower skin 4;

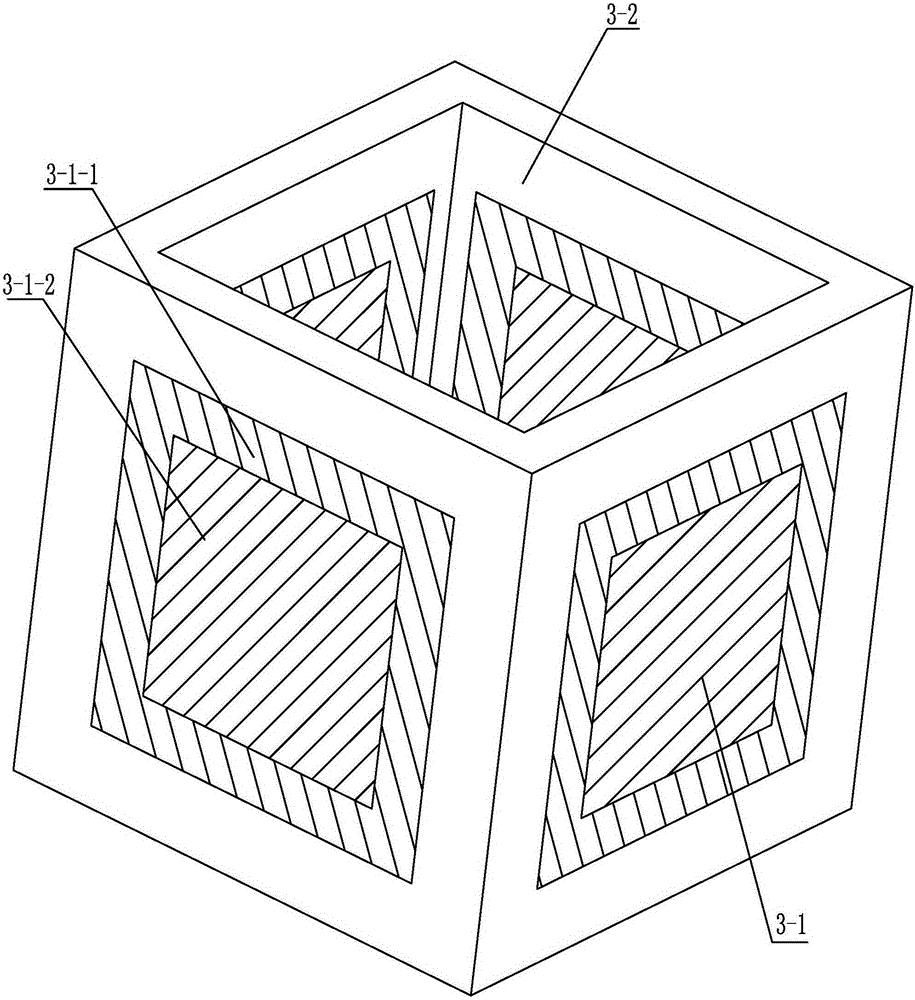

[0010] The upper skin 1 is arranged above the lower skin 4, and between the upper skin 1 and the lower skin 4 is arranged a local resonance type phononic crystal vibration isolation component 2 glued to the two. The sub-crystal vibration isolation component 2 is composed of a plurality of local resonance type phononic crystal units 3 uniformly distributed along the lateral and longitudinal periods, adjacent local resonance type phononic crystal units 3 are glued together, and each local resonance type acoustic The sub-crystal unit 3 is a regular prism structure with local oscillators 3-1 on each side. The local oscillator 3-1 is a ring structure with inner and outer double layers glued together. The l...

specific Embodiment approach 2

[0011] Embodiment 2: The local vibrator 3-1 in this embodiment is a regular polygon or circular ring structure in which the inner and outer double layers are glued together. With such arrangement, the structure is simple, the design is reasonable, and the practical needs are met. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The regular prism frame matrix 3-2 of the local resonance type vibration isolation phononic crystal unit of this embodiment is a cube, regular pentagonal prism or regular hexagonal prism frame matrix. Such arrangement has a simple structure and meets actual needs. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com