JS elastic waterproof coating

A waterproof coating and elastic technology, applied in the field of polymer cement waterproof coating, high-performance elastic building waterproof coating, JS elastic waterproof coating, can solve the problems that waterproof coating cannot adapt to buildings, lose waterproof effect, poor environmental protection, etc., and achieve hydration Short curing time, long construction open time, easy to paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A high-performance elastic waterproof coating is composed of 40% powder and 60% liquid by weight.

[0020] The liquid material is composed of the following raw materials in weight percentage: 80% of pure acrylic acid emulsion, 18% of water, 1.8% of water reducer, and 0.2% of antifungal agent.

[0021] The powder is composed of the following raw materials in weight percentage: 40% of Portland cement, 30% of quartz sand, 29.5% of quartz powder and 0.5% of cellulose.

[0022] The preparation method is as follows: firstly, the above-mentioned liquid material and powder are mixed according to the weight ratio, and then the liquid material is poured into a clean mixing container, and the powder is slowly added while using mechanical stirring, and fully stirred until no powder lumps are formed. Uniform flow glue of granules.

[0023] The selected raw materials are as follows:

[0024] The pure acrylic emulsion is selected from the pure acrylic emulsion LWJ-711 of Jiangsu Liw...

Embodiment 2

[0033] A high-performance elastic waterproof coating is composed of 65% powder and 35% liquid by weight.

[0034] The liquid material is composed of the following raw materials in weight percentage: 94% of pure acrylic acid emulsion, 5% of water, 0.9% of water reducer, and 0.1% of antifungal agent.

[0035] The powder is composed of the following raw materials in weight percentage: 65% of Portland cement, 15% of quartz sand, 19.7% of quartz powder and 0.3% of cellulose.

[0036] The preparation method is as follows: firstly, the above-mentioned liquid material and powder components are respectively mixed according to the weight ratio, and then the liquid material is poured into a clean mixing container, and the powder is slowly added while stirring with a mechanical stirrer, and fully stirred until a powder-free Uniform flow glue without particles.

[0037] The selected raw materials are the same as in Example 1.

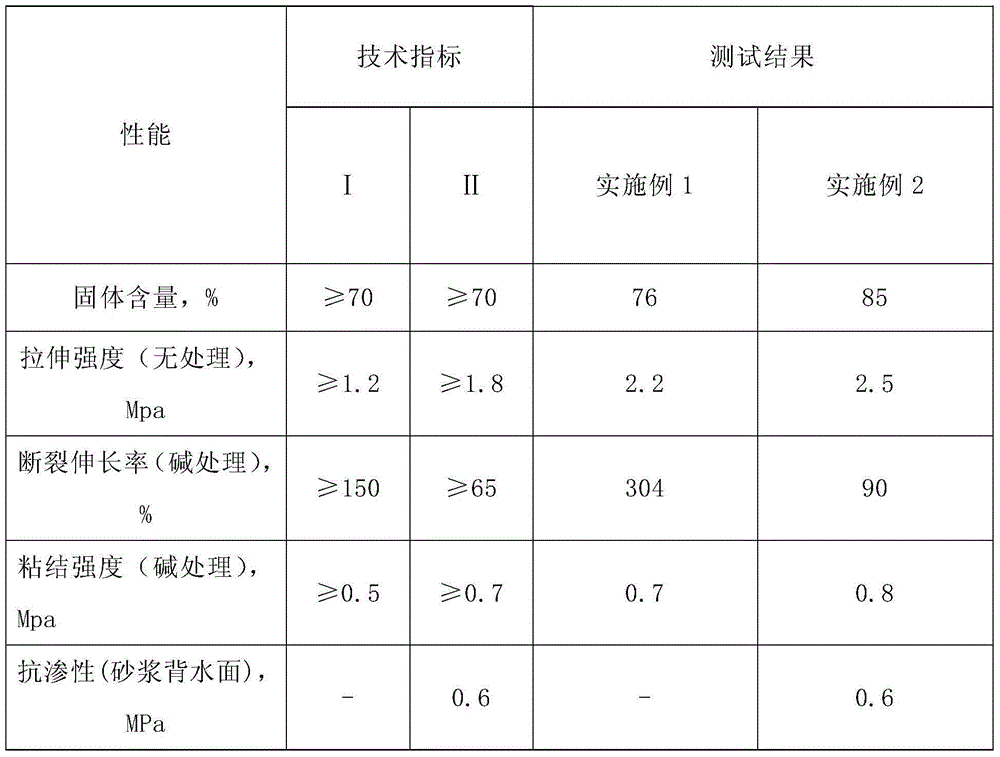

[0038] The above-mentioned Example 1 and Example 2 were test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com