A waste water treatment system and a method

A waste water treatment system and biochemical treatment device technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high investment, low stability of treatment effect, large bed layer area etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Such as figure 1 Shown, a kind of waste water treatment device comprises: ozone oxidation device and biochemical treatment device, and ozone oxidation device comprises ozone destroyer and oxidation reactor,

[0115] The biochemical treatment unit includes two-phase expanded bed, oxygen dissolver and circulation pump;

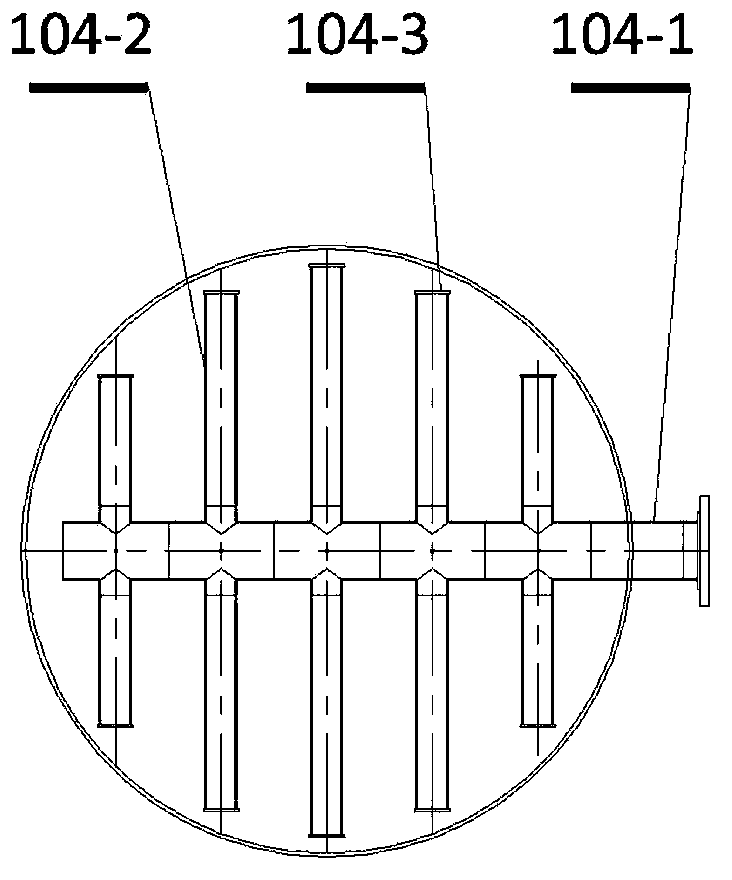

[0116] The two-phase expanded bed a is a two-section vertical cylindrical structure with a circular cross-section, the upper section has a large section, and the lower section has a small section. From bottom to top, there are respectively a gas-water distribution area 101, a packing area 102, and a water outlet area 103. An air distribution system 105 and a water distribution system 104 are respectively set up at the upper and lower parts of the air-water distribution area. The water outlet area 103 is thicker at the top and thinner at the bottom, and is connected with the filling area 102 through a transition section in the shape of a bell mouth. A thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com