A cutting-free scaffold fastener bolt maintenance machine

A technology for scaffolding and maintenance machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of poor operation safety and simple functions, and achieve the effects of high work efficiency, reduced cutting steps, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

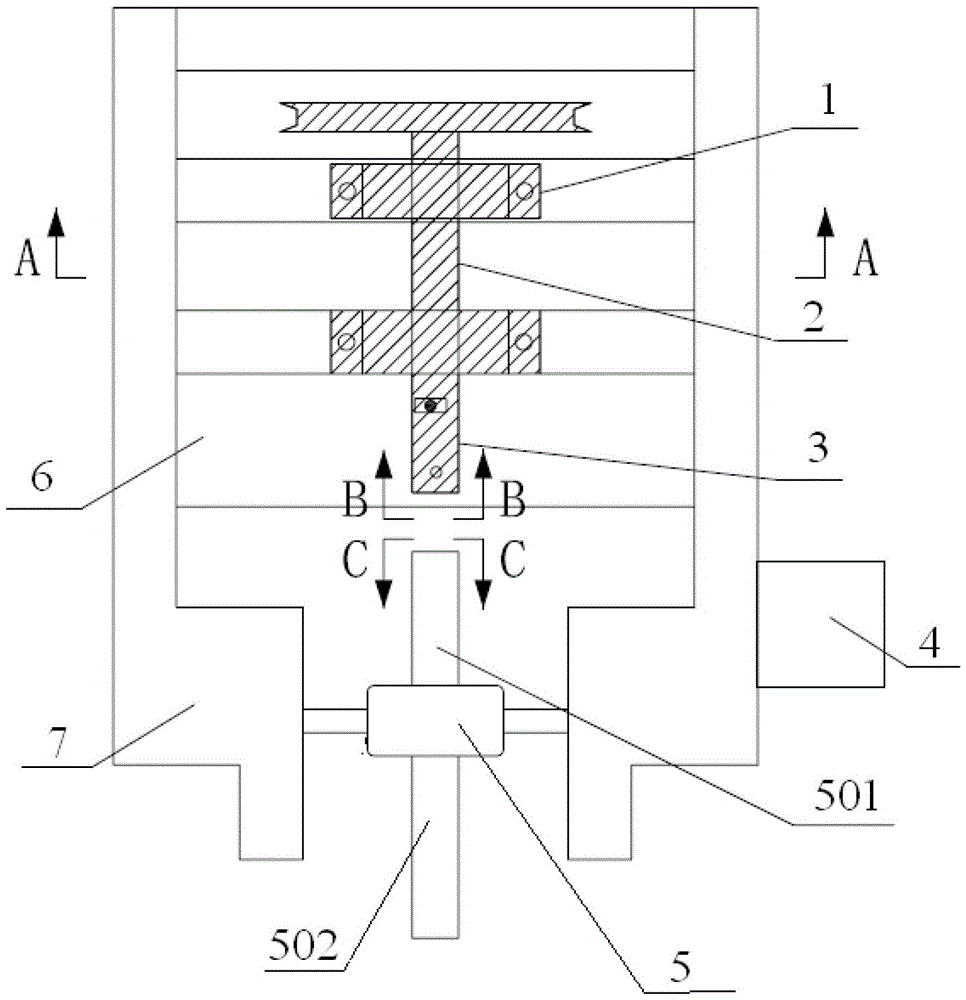

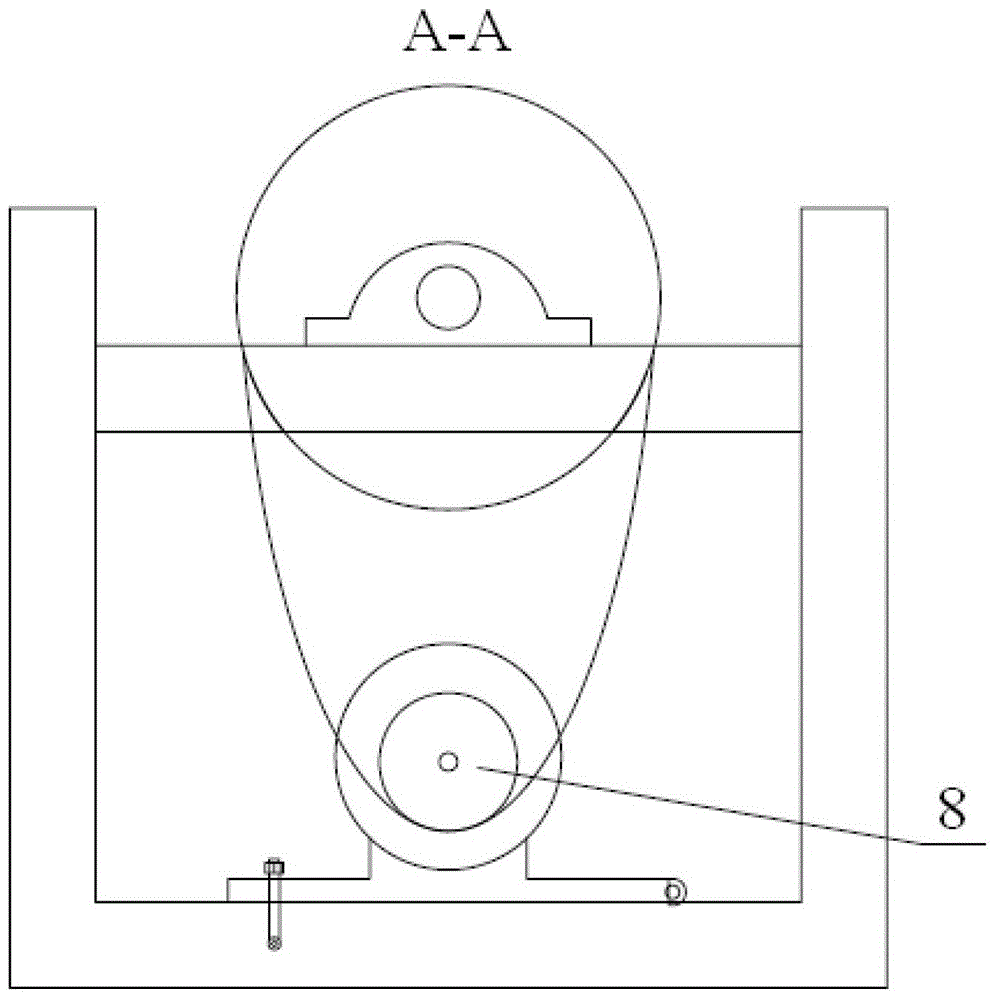

[0016] Such as figure 1 , figure 2 As shown, a cutting-free scaffold fastener bolt maintenance machine of the present invention includes a U-shaped pallet support 7 extending in the axial direction, a motor 8 fixed in the pallet support 7, and the motor 8 Through the intermediate shaft 2 driven by the belt, the axis of the intermediate shaft 2 is parallel to the axis of the motor shaft of the motor 8 and is located above the axis of the motor shaft. a bearing housing 1 support;

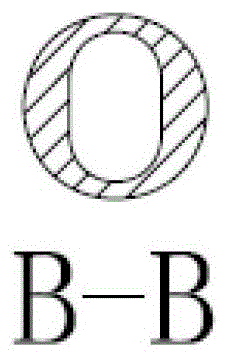

[0017] One end of the intermediate shaft 2 is coaxially fixed with one end of the fast T-type wrench 3 by a bolt; as image 3 As shown, the other end of the quick T-type wrench 3 is provided with a first groove, and the shape of the first groove is matched with the bolt cap of the cutting-free scaffold fastener;

[0018] Also includes a nut wrench assembly 5 that is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com