Conduction-cooled superconducting rotating machine

A technology of superconducting rotors and refrigerators, applied in cooling/ventilation devices, usage of superconductor elements, electromechanical devices, etc., can solve problems such as complex structures and increased failure factors, and achieve the effect of conduction cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

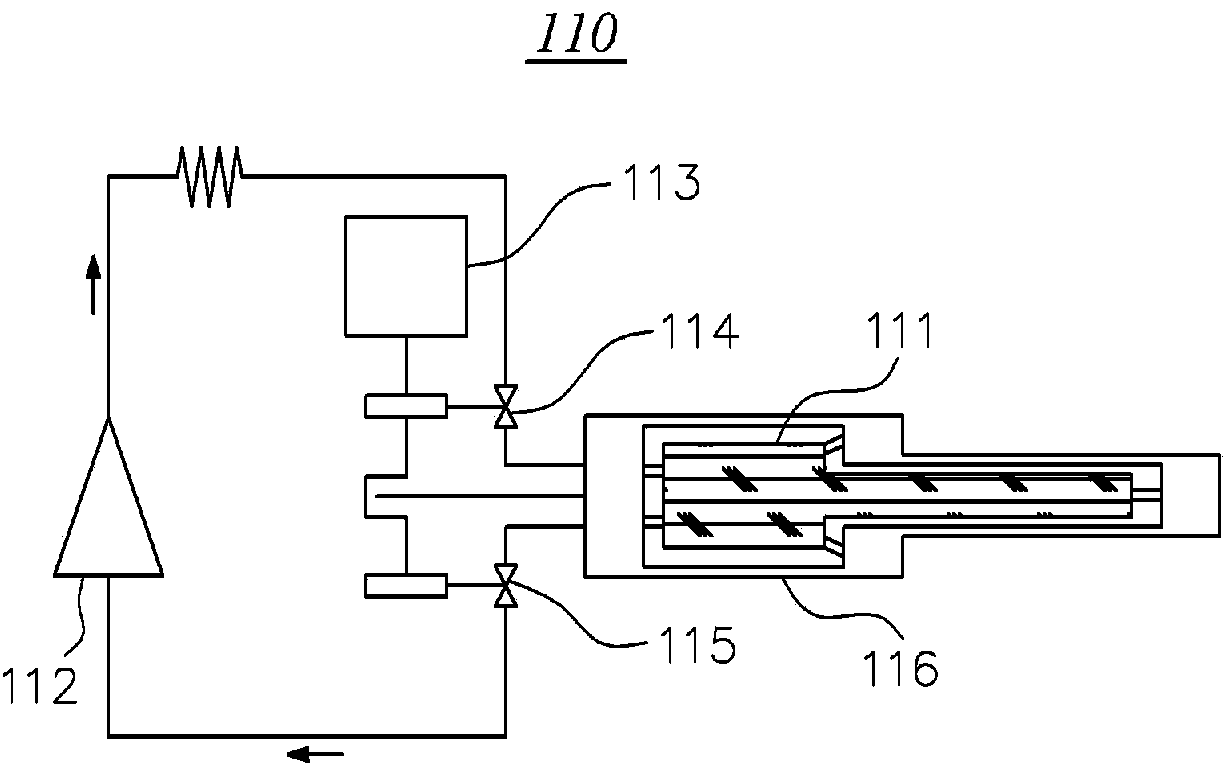

Image

Examples

Embodiment Construction

[0028] The embodiments and configurations described in the drawings are for illustrative purposes only and do not represent the full technical scope of the present invention, and therefore, it should be understood that various equivalents and modifications exist at the time of filing this application. Although the preferred embodiment of the present invention has been described for illustrative purposes, those skilled in the art will appreciate that various modifications, additions and substitutions can be made without departing from the scope and spirit of the invention as disclosed in the appended claims. It is possible.

[0029] The terms and terms in the specification and claims should be understood as being related to the technical scope of the present invention on the basis that the inventor properly defines the concept of terms to best explain the present invention.

[0030] The words "first" and "second" may be used to refer to various components, but the components ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com