Method and device for compensating for resistance process deviation, resistors and RC oscillators

A technology of process deviation and compensation method, applied in the direction of electrical components, impedance network, etc., can solve the problems affecting the clock accuracy, affecting the performance of the application circuit, resistance deviation, etc., to achieve the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

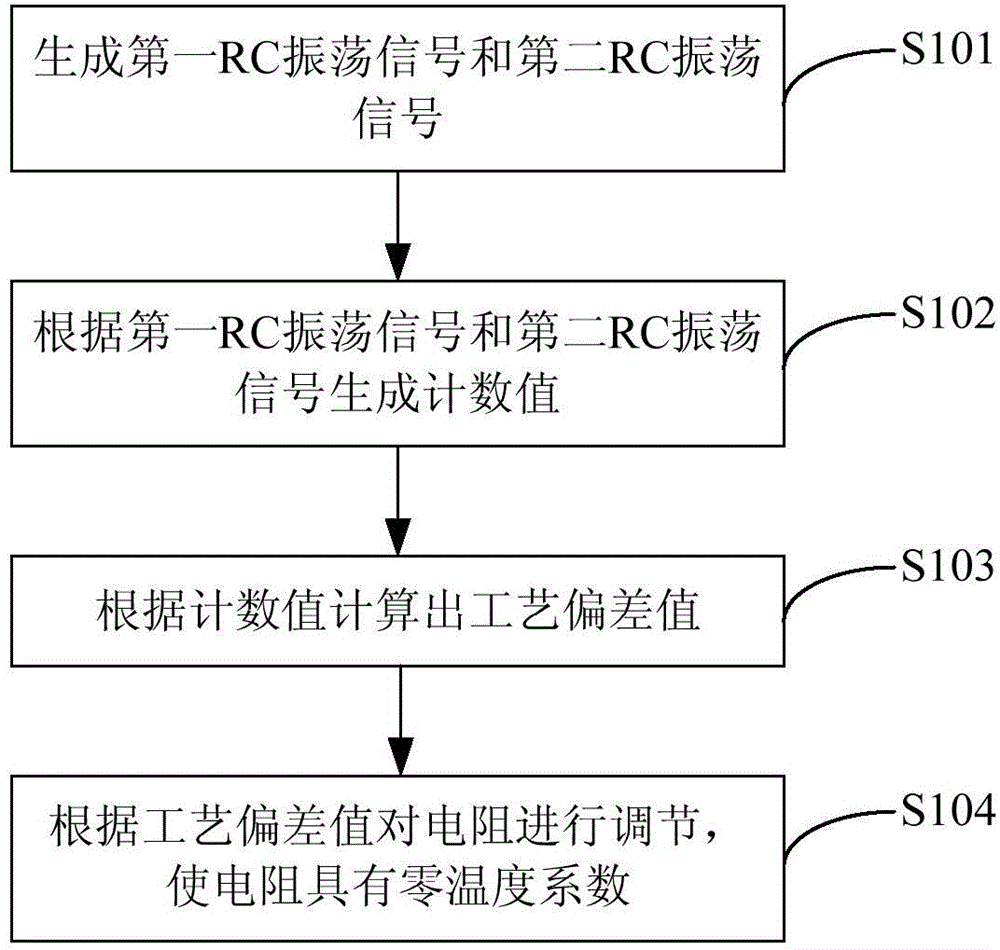

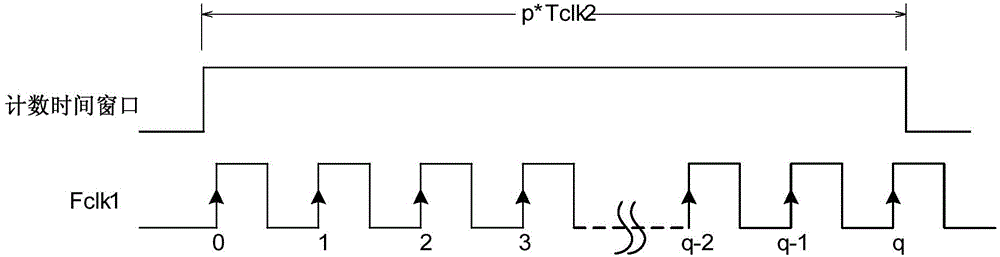

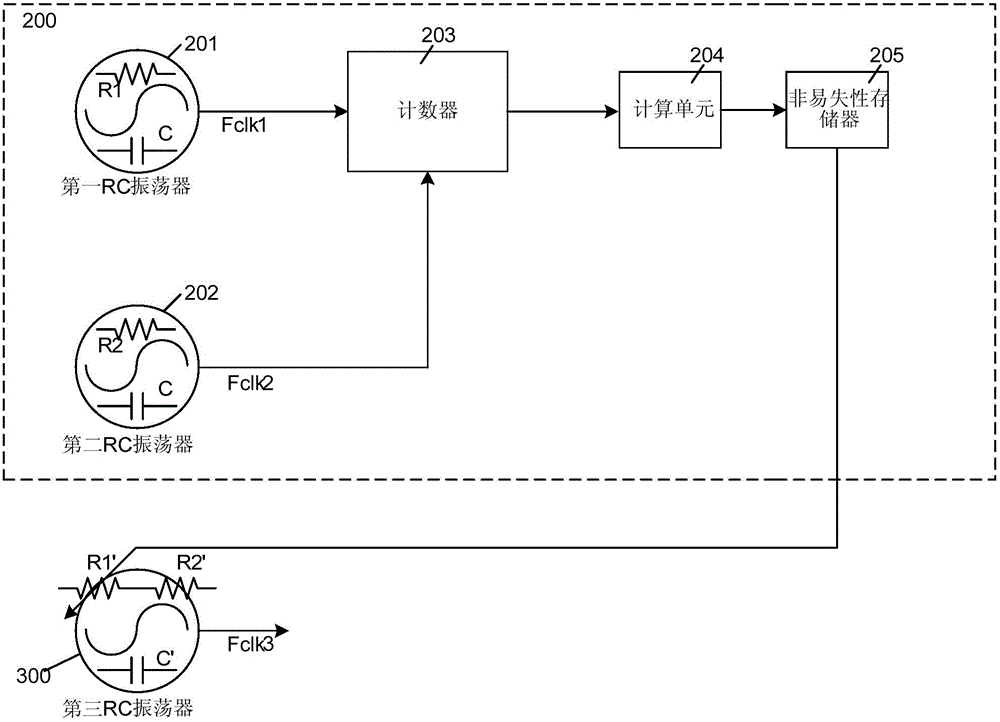

[0033] In the embodiment of the present invention, the clock of one RC oscillator is used to count the clock of another RC oscillator, and the count value reflecting the relative process deviation information between resistors with opposite temperature coefficients is calculated by the calculation unit to calculate the resistance process Then, the resistance process deviation value is compensated for the resistance of the third RC oscillator, so that the resistance of the third RC oscillator can reliably and effectively become a zero temperature coefficient resistance, and the purpose of temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com