tdo edge guide device for lithium battery diaphragm production line

A lithium battery separator and production line technology, which is applied in the field of TDO edge guide devices, can solve the problems that the edge guide auxiliary tool cannot be accommodated, the film edge cannot be effectively flattened, the film edge is wrinkled and curled, etc. The effect is considerable, the effect of reducing the film breaking rate in transverse drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

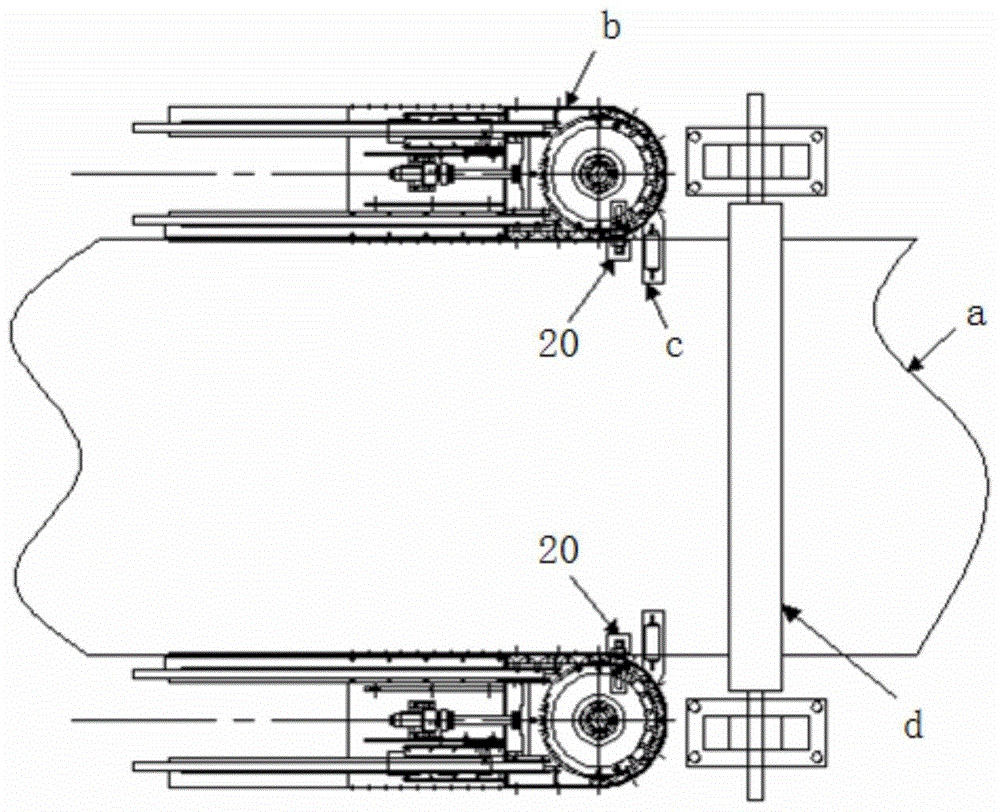

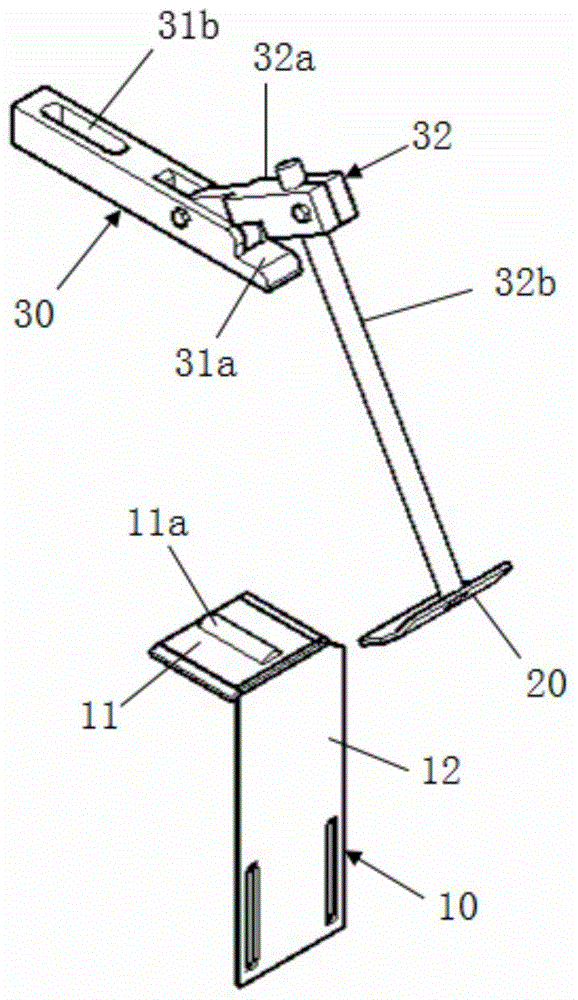

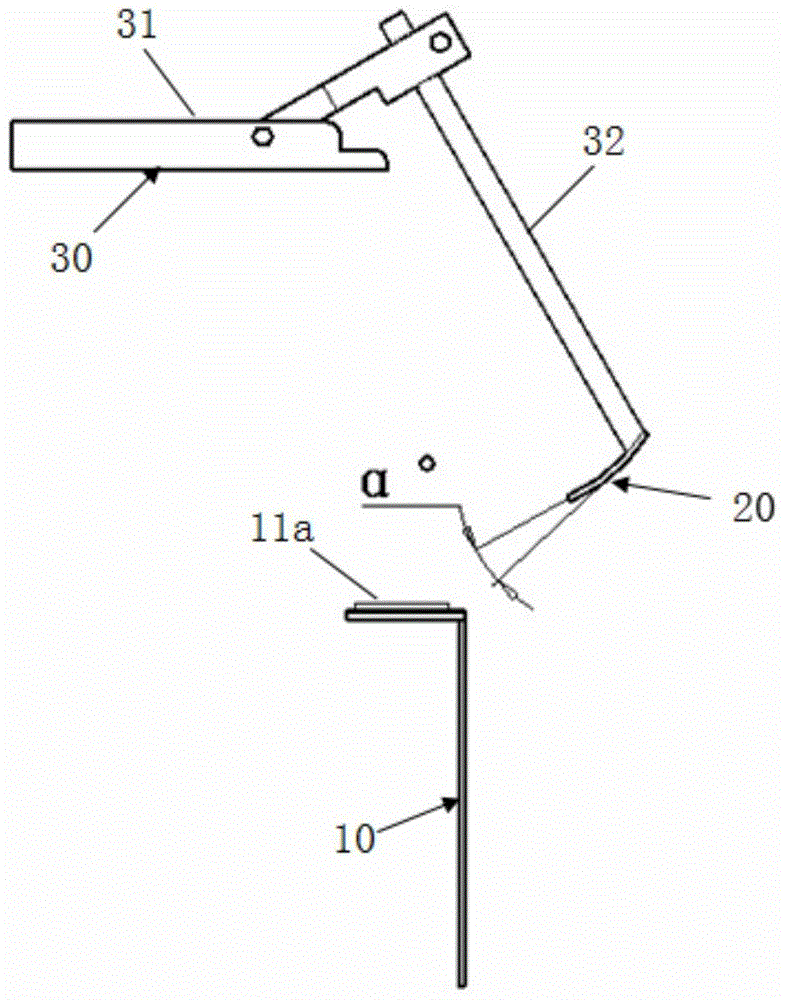

[0024] For ease of understanding, combined here Figure 1-3 The specific implementation structure and work flow of the present invention are described as follows:

[0025] The specific structure of the present invention is as Figure 2-3 As shown, it includes a supporting plate 10 and a pressing plate 20 which are separated on the membrane surfaces of both sides of the lithium battery separator. Among them, the supporting plate 10 located below the lithium battery diaphragm is affixed to the side shield of the horizontal drawing machine, and the pressing plate 20 located above the lithium battery diaphragm is directly fixed by the hinge design of the extension arm 32 and the fixed base 31. At the upper shell of the horizontal stretching machine. The fine-tuning of the pressure plate 20 based on the lithium battery diaphragm is realized by fixing the waist-shaped hole 31b on the base 31 on the one hand; Axis sliding socket structure to achieve. The supporting plate 10 uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com