LED packaging structure and method, display device and illuminating device

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of small viewing angle, poor firefly of liquid crystal display devices, and difficult realization, etc., to expand the irradiation range, improve the irradiation effect, and the viewing angle Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

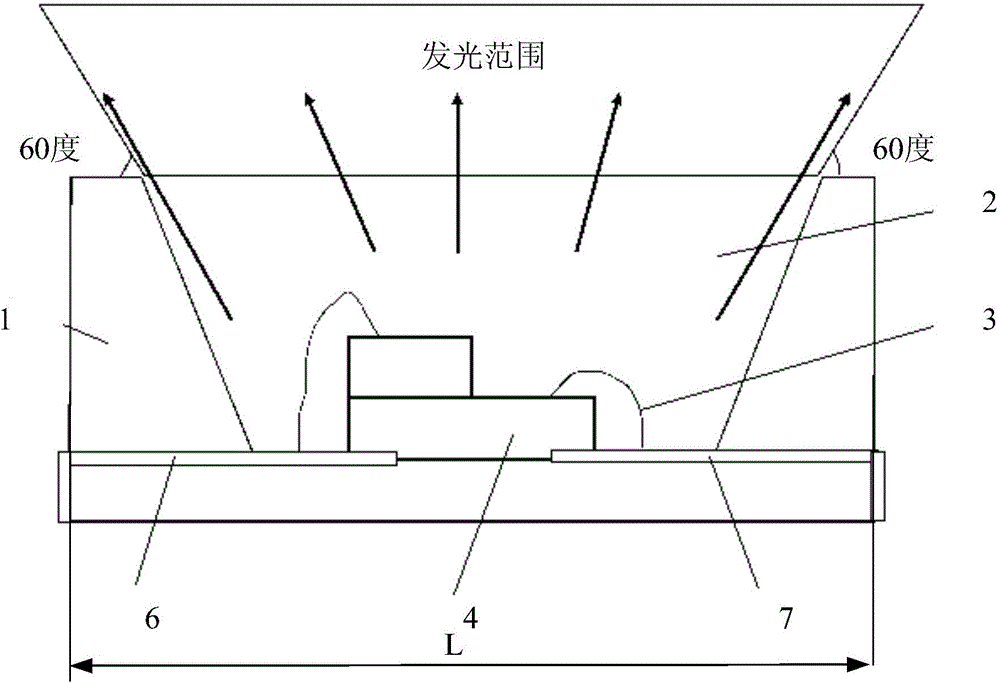

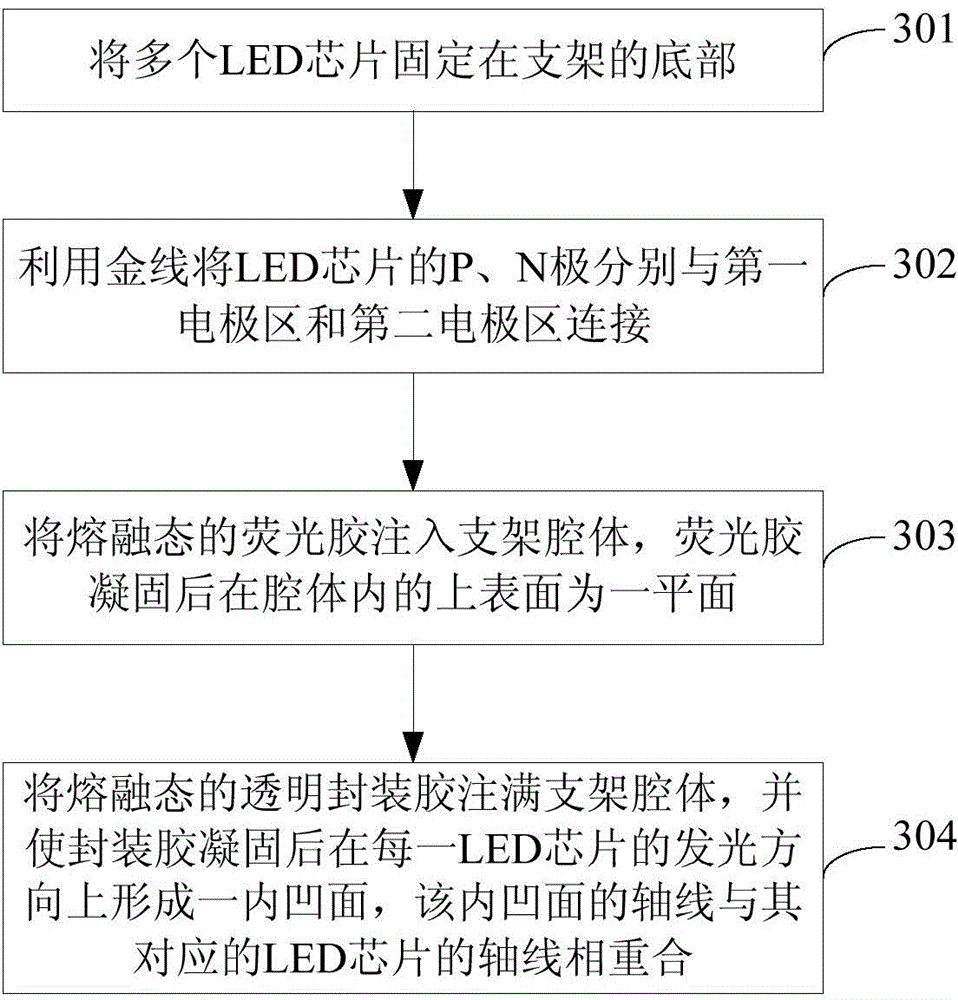

[0091] Such as image 3 As shown, the LED packaging method of this embodiment specifically includes:

[0092] Step 301: fixing multiple LED chips on the bottom of the bracket;

[0093] Such as Figure 4 As shown, the stent 1 has a cavity, and the bottom of the cavity is a metal layer, and the metal layer includes a first electrode area 6 and a second electrode area 7 . Specifically, the LED chip 4 can be fixed on the metal layer by using a die-bonding glue, and the die-bonding glue can be epoxy resin or silica gel. It should be noted that Figure 4 Only the situation of one LED chip 4 is drawn in the figure.

[0094] Step 302: Connect the P and N poles of the LED chip to the first electrode area and the second electrode area respectively with gold wires;

[0095] The P and N poles of the plurality of LED chips 4 are respectively connected to the first electrode region 6 and the second electrode region 7 of the metal layer by gold wires 3 .

[0096] Step 303: inject molten...

Embodiment 2

[0102] Such as Image 6 As shown, the LED packaging method of this embodiment specifically includes:

[0103] Step 501: fixing multiple LED chips on the bottom of the bracket;

[0104] Such as Figure 7 As shown, the stent 1 has a cavity, and the bottom of the cavity is a metal layer, and the metal layer includes a first electrode area 6 and a second electrode area 7 . Specifically, the LED chip 4 can be fixed on the metal layer by using a die-bonding glue, and the die-bonding glue can be epoxy resin or silica gel. It should be noted that Figure 7 Only the situation of one LED chip 4 is drawn in the figure.

[0105] Step 502: Connect the P and N poles of the LED chip to the first electrode area and the second electrode area respectively with gold wires;

[0106] The P and N poles of the plurality of LED chips 4 are respectively connected to the first electrode region 6 and the second electrode region 7 of the metal layer by gold wires 3 .

[0107] Step 503: inject molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com