Photoelectric composite cable

A photoelectric composite cable and cable core technology, which is applied in the direction of insulated cables, communication cables, cables, etc., can solve the problem of large outer diameter of the cable core, and achieve the goals of reducing the outer diameter of the cable core, increasing the strength, and reducing the outer diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

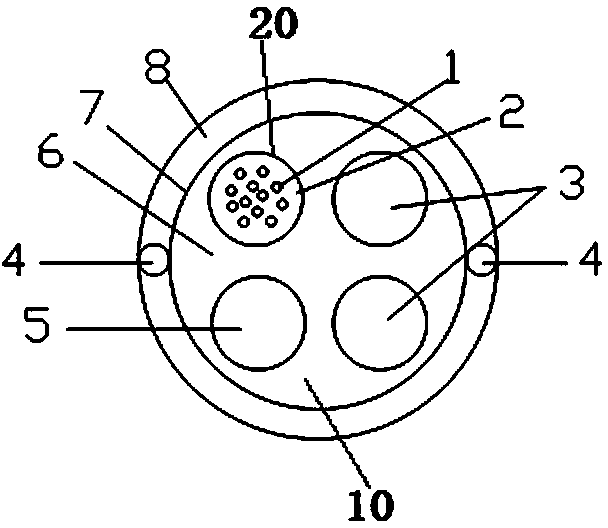

[0018] Such as figure 1 As shown, an embodiment of a photoelectric composite cable, the photoelectric composite cable in this embodiment includes an outer sheath 8 and a cable core 10 arranged in the outer sheath 8, and the cable core 10 includes optical fiber sleeves 20 arranged in parallel at intervals , copper wire 3, filling rope 5 and cable paste 6 filled between the optical fiber sleeve 20, copper wire 3, filling rope 5, wherein two copper wires 3 are provided, the optical fiber sleeve 20, two copper wires 3 and the filling The rope 5 is arranged in the shape of a "field", and the outer sheath 8 is provided with a steel strip longitudinal wrap 7 covering the outer peripheral surface of the cable core 10, and the wall of the outer sheath 8 is provided with the cable core 10 reinforcements 4 extending in parallel. The reinforcements 4 are metal reinforcements that are in contact with the outer peripheral surface of the steel strip longitudinal wrap 7. The metal reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com