Method for analyzing and estimating precision of inertial device based on vibration performance

An inertial device and vibration acceleration technology, applied in the field of inertial devices, can solve problems such as no consideration, uncertainty in the accuracy life estimation and prediction of inertial devices, and single criteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The working principle and working process of the present invention will be further explained below in conjunction with the accompanying drawings.

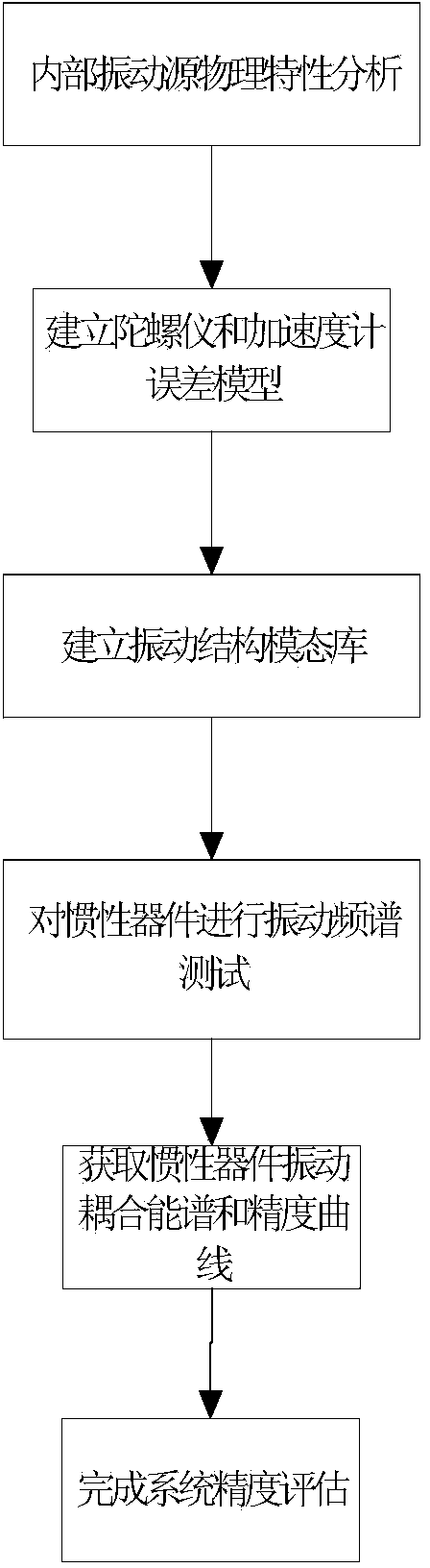

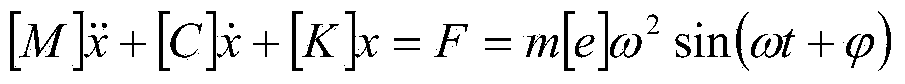

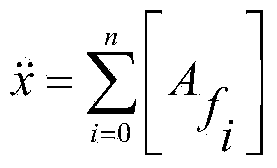

[0050] The principle realized by the present invention is: analyze the vibration performance of the internal vibration source of the inertial device, establish a relevant practical engineering model (including vibration influence), aim at the vibration spectrum, establish the structural mode library of the inertial device, and obtain the vibration that affects the error model The characteristic mode library uses the vibration tester to detect the full frequency spectrum of the vibration of the inertial device, establishes the characteristic of the vibration characteristic mode spectrum, and the correlation function and curve of the error model, and completes the performance evaluation and accuracy life prediction of the inertial device.

[0051] like figure 1 As shown, a method for evaluating the accuracy of inertial devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com