Neuronal and neuroglial cell ordered co-culture device and preparation method thereof, and neuronal and neuroglial cell ordered co-culture method

A glial cell and neuron technology, applied in the field of cell biology, can solve the problems of cell floating, short cell survival time, and inability to ensure that neurons and glial cells are in a good time period for cultivation at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1) Take a 3*3 cm cover glass, first soak the surface in a solution of fecivic acid (conc. Milliliter of 0.1% poly-lysine, incubate for 1.0 hour, absorb the remaining solution, wash 3 times with phosphate buffer (pH 7.4), dry in the air, and set aside;

[0067]2) Using micromachining technology, prepare a group of concave linear microstructure units on a plexiglass plate, the concave linear microstructure units are composed of two grooves arranged in sequence from left to right, wherein the left The cross section of the side groove is rectangular, the length is 1.0 cm, and the width is 0.5 cm; the cross section of the right groove is rectangular, the length is 1.0 cm, and the width is 1.0 cm; the left groove and the right groove The distance between them is 2000 microns;

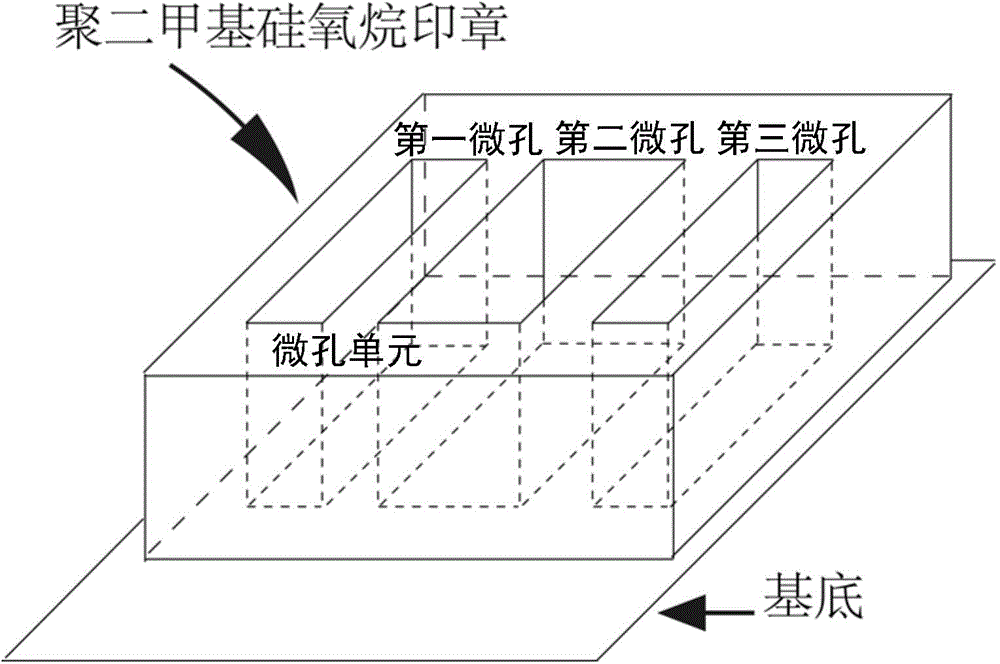

[0068] 3) The plexiglass plate with one group of concave linear microstructure units obtained in step 2) is turned over twice with polydimethylsiloxane to obtain a polydimethylsiloxane template, the p...

Embodiment 2

[0077] 1) Take a cell culture dish with a diameter of 25 mm, add 1.0 ml of 0.1% L-polylysine dropwise on the bottom surface, incubate for 1.0 hour, absorb the remaining solution, and wash with phosphate buffer (pH7.4) 3 times, dry and set aside;

[0078] 2) Using micromachining technology, prepare at least one group of concave linear microstructure units on a plexiglass plate, the concave linear microstructure units are composed of three grooves arranged in sequence from left to right; wherein, the The cross section of the groove on the left side is rectangular, with a length of 1.8 cm and a width of 0.5 cm; the cross section of the middle groove is rectangular, with a length of 1.8 cm and a width of 1.1 cm; the cross section of the right groove is It is rectangular, with a length of 1.8 cm and a width of 0.5 cm; the distance between the left groove and the middle groove, and the distance between the middle groove and the right groove is 1000 microns;

[0079] 3) The plexigla...

Embodiment 3

[0088] 1) Take a cell culture dish with a diameter of 25 mm, add 1.0 ml of 0.1% poly-lysine dropwise on the bottom surface, incubate for 1.0 hour, absorb the remaining solution, and wash 3 times with phosphate buffer (pH7.4) , dry and set aside;

[0089] 2) Using micromachining technology, prepare at least one group of concave linear microstructure units on the plexiglass plate, the concave linear microstructure units are composed of three grooves arranged in sequence from left to right; wherein, the left The cross section of side groove is rectangular, and length is 1.8 centimeters, and width is 0.8 centimeter; The cross section of described middle groove is rectangular, and length is 1.8 centimeters, and width is 0.5 centimeter; The cross section of described right side groove is Rectangular with a length of 1.8 cm and a width of 0.8 cm; the distance between the left groove and the middle groove, and the middle groove and the right groove are both 500 μm;

[0090] 3) The pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com