Sulfur-dioxide-free full juice fermented kiwifruit wine and production process thereof

A technology of sulfur dioxide and kiwi fruit, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of no basic process mode and complex functions, and achieve the effects of ensuring normal alcohol fermentation, reducing water activity, and enhancing antiseptic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

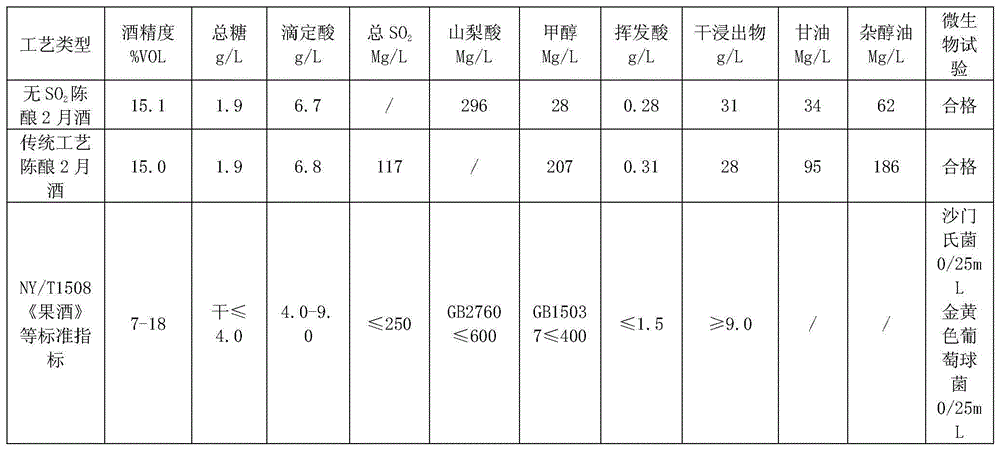

Examples

Embodiment 1

[0058] A kind of sulfur dioxide-free full-juice fermented kiwi fruit wine is prepared by the following method:

[0059] 1. Fruit selection, disinfection and cleaning: The kiwi fruit for wine making should be fully ripe, juicy, high in sugar, thin in skin, and tender in flesh. The kiwi fruit with fluff should be depilated through a fruit grinder; for hard and immature kiwi fruit Fruits can be processed through post-ripening. The selected fruits are sterilized by soaking in 0.02% potassium permanganate solution for 5 minutes. At the same time, the sediment, insect eggs and other sundries are washed away, and then rinsed with clean water, drained and set aside.

[0060] 2. Crushed and squeezed juice, added D-isoascorbic acid for anti-oxidation, and nisin for antibacterial: when crushing fresh fruit with a crusher, add 0.2g / kg D-isoascorbic acid for anti-oxidation (the ratio of 0.2g / kg here Refers to the ratio of D-erythorbic acid to fresh fruit), used alone or in combination wit...

Embodiment 2

[0092] A kind of sulfur dioxide-free full-juice fermented kiwi fruit wine is prepared by the following method:

[0093] 1. Fruit selection, disinfection and cleaning: The kiwi fruit for wine making should be fully ripe, juicy, high in sugar, thin in skin, and tender in flesh. The kiwi fruit with fluff should be depilated through a fruit grinder; for hard and immature kiwi fruit Fruits can be processed through post-ripening. The selected fruits are sterilized by soaking in 0.02% potassium permanganate solution for 5 minutes. At the same time, the sediment, insect eggs and other sundries are washed away, and then rinsed with clean water, drained and set aside.

[0094] 2. Crushed and squeezed juice, added D-isoascorbic acid for anti-oxidation, and nisin for antibacterial: when crushing fresh fruit with a crusher, add 0.2g / kg D-isoascorbic acid for anti-oxidation (the ratio of 0.2g / kg here Refers to the ratio of D-erythorbic acid to fresh fruit), used alone or in combination wit...

Embodiment 3

[0125] A kind of sulfur dioxide-free full-juice fermented kiwi fruit wine is prepared by the following method:

[0126] 1. Fruit selection, disinfection and cleaning: The kiwi fruit for wine making should be fully ripe, juicy, high in sugar, thin in skin, and tender in flesh. The kiwi fruit with fluff should be depilated through a fruit grinder; for hard and immature kiwi fruit Fruits can be processed through post-ripening. The selected fruits are sterilized by soaking in 0.02% potassium permanganate solution for 5 minutes. At the same time, the sediment, insect eggs and other sundries are washed away, and then rinsed with clean water, drained and set aside.

[0127] 2. Crushed and squeezed juice, added D-isoascorbic acid for anti-oxidation, and nisin for antibacterial: when crushing fresh fruit with a crusher, add 0.2g / kg D-isoascorbic acid for anti-oxidation (the ratio of 0.2g / kg here Refers to the ratio of D-erythorbic acid to fresh fruit), used alone or in combination wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com