Solar sludge constant temperature drying harmless treatment device and method

A harmless treatment and solar energy technology, applied in dehydration/drying/thickened sludge treatment, energy wastewater treatment, combustion methods, etc., can solve the problem of difficult removal of capillary bound water and internal bound water, complex water composition, and large energy consumption and other problems, to achieve the effect of convenient oven temperature control, temperature maintenance and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

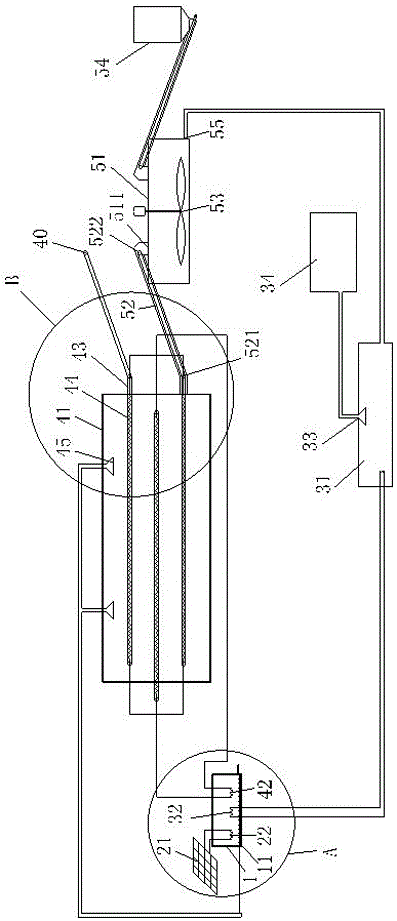

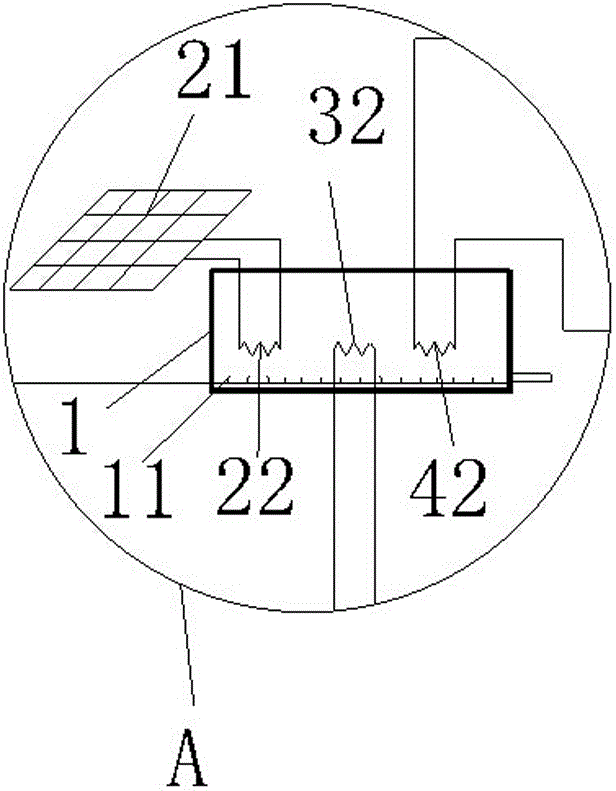

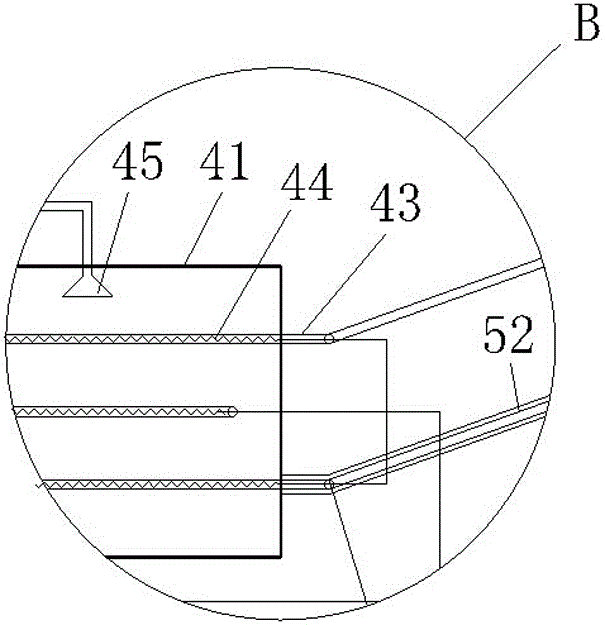

[0030]Solar sludge constant temperature drying and harmless treatment device, including hot water storage pool 1, solar heat collecting device, sludge incineration device, sludge drying device and finished sludge storage device, solar heat collecting device including solar heat collecting plate 21 and solar heat exchanger 22, the sludge incineration device includes an incinerator 31, an incinerator heat exchanger 32, an incineration waste gas collection device 33 and an incineration waste gas treatment device 34, and the sludge drying device includes an oven 41, an oven heat exchanger 42, The oven sludge conveyor belt 43, the heat exchange unit 44 in the oven and the drying exhaust gas collection device 45, the finished sludge storage device includes the finished sludge storage tank 51, the closed sludge conveyor belt 52, the sludge stirring device 53 and the combustion aid Storage tank 54; the solar heat exchanger 22, the incinerator heat exchanger 32 and the oven heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com