Full steering moving chassis

A mobile chassis and omni-directional mobile technology, applied in steering mechanisms, motor vehicles, transportation and packaging, etc., can solve the problems of large number of motors, bulky flexibility, complex control, etc., to achieve high flexibility, compact chassis structure, and Good effect of emptiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

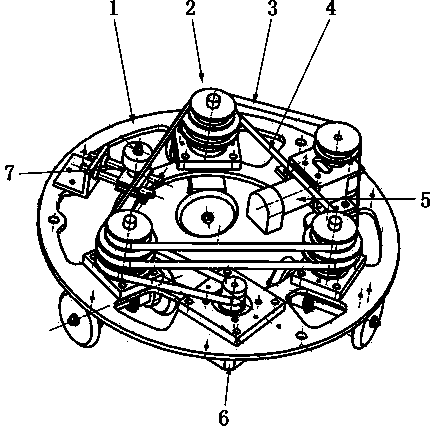

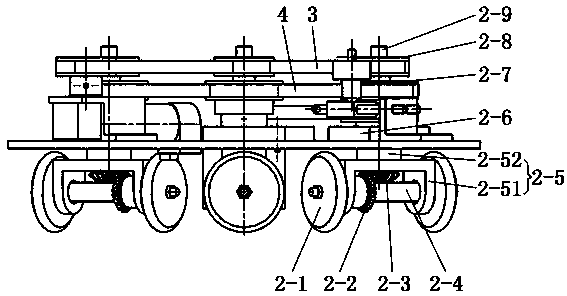

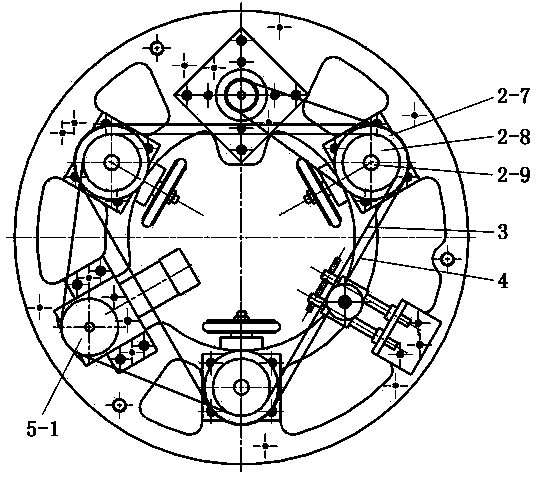

[0018] Figure 1 to Figure 4 The shown omni-directional mobile chassis mainly includes a base plate 1, an omni-directional mobile unit 2, a travel drive motor 5, a steering drive motor 6, a first transmission belt 3, a second transmission belt 4 and a tensioning device 7. A group of omnidirectional mobile units 2, each group of omnidirectional mobile units 2 includes wheels 2-1, wheel shafts 2-4, active bevel gears 2-3, passive bevel gears 2-2, vertical shafts 2-9, and driving wheels 2 -8, steering support frame 2-5 and steering drive wheel 2-7; two opposite wheels 2-1 are respectively installed and fixed at the two ends of the wheel shaft 2-4, and the steering support frame 2-5 has a vertical wear The sleeve 2-52 arranged on the base plate 1 and the fork-shaped bracket 2-51 integrally formed with the sleeve 2-52 under the base plate 1, see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com