A foam brick cutting device with smoother sliding

A cutting device and foamed brick technology, which is applied in metal processing, lubricating oil containers, engine components, etc., can solve the problems of affecting the operation of the foamed brick cutting device, the sliding block is not smooth, etc., and achieves a simple structure and reduces the scrap rate. , the effect of reducing motor power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

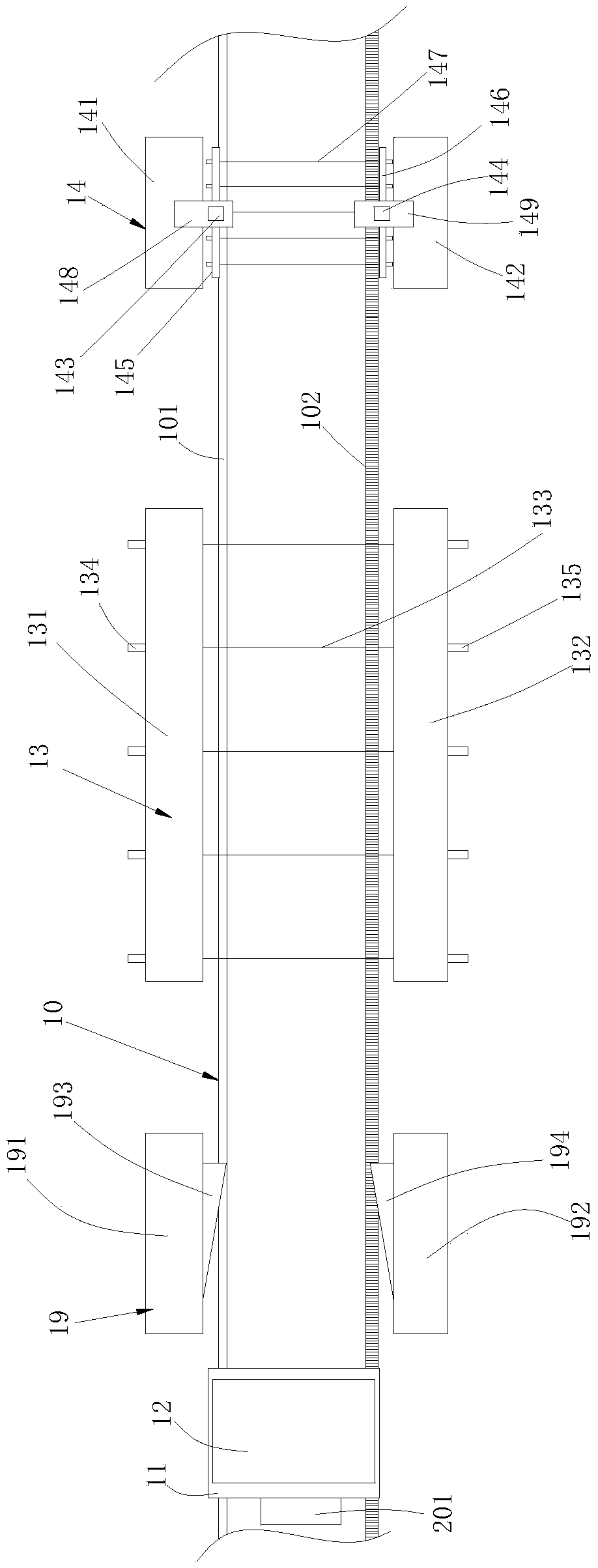

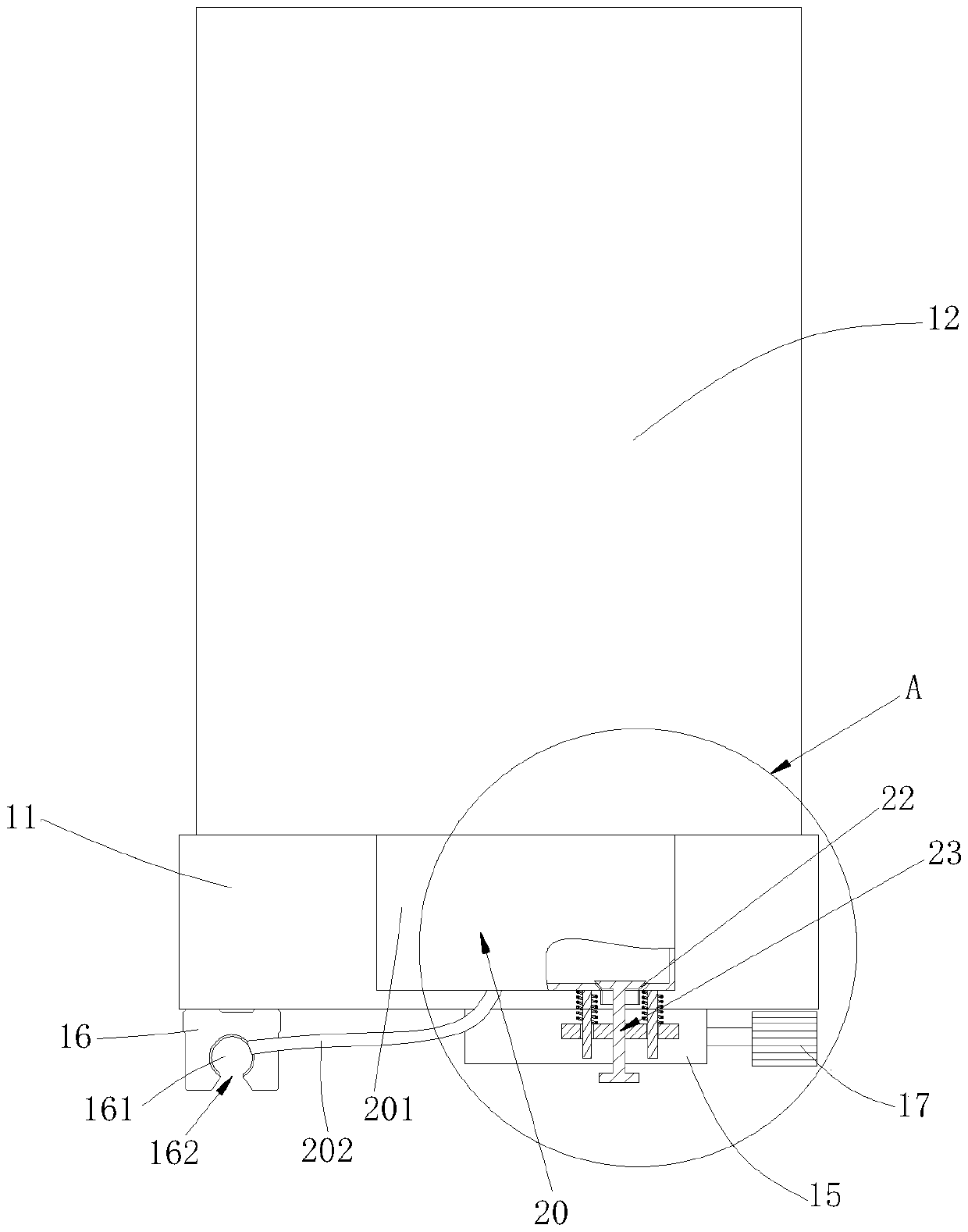

[0023] refer to figure 1 , a foam brick cutting device that slides more smoothly, comprising a track 10, a supporting plate 11 slidably installed on the track 10, a foam brick 12 placed on the supporting plate 11, and used for cutting the foam brick 12 A horizontal cutting device 13 for cutting the foam brick 12 into small blocks along the horizontal direction, and a vertical cutting device 14 for cutting the foamed brick 12 into small blocks along the vertical direction.

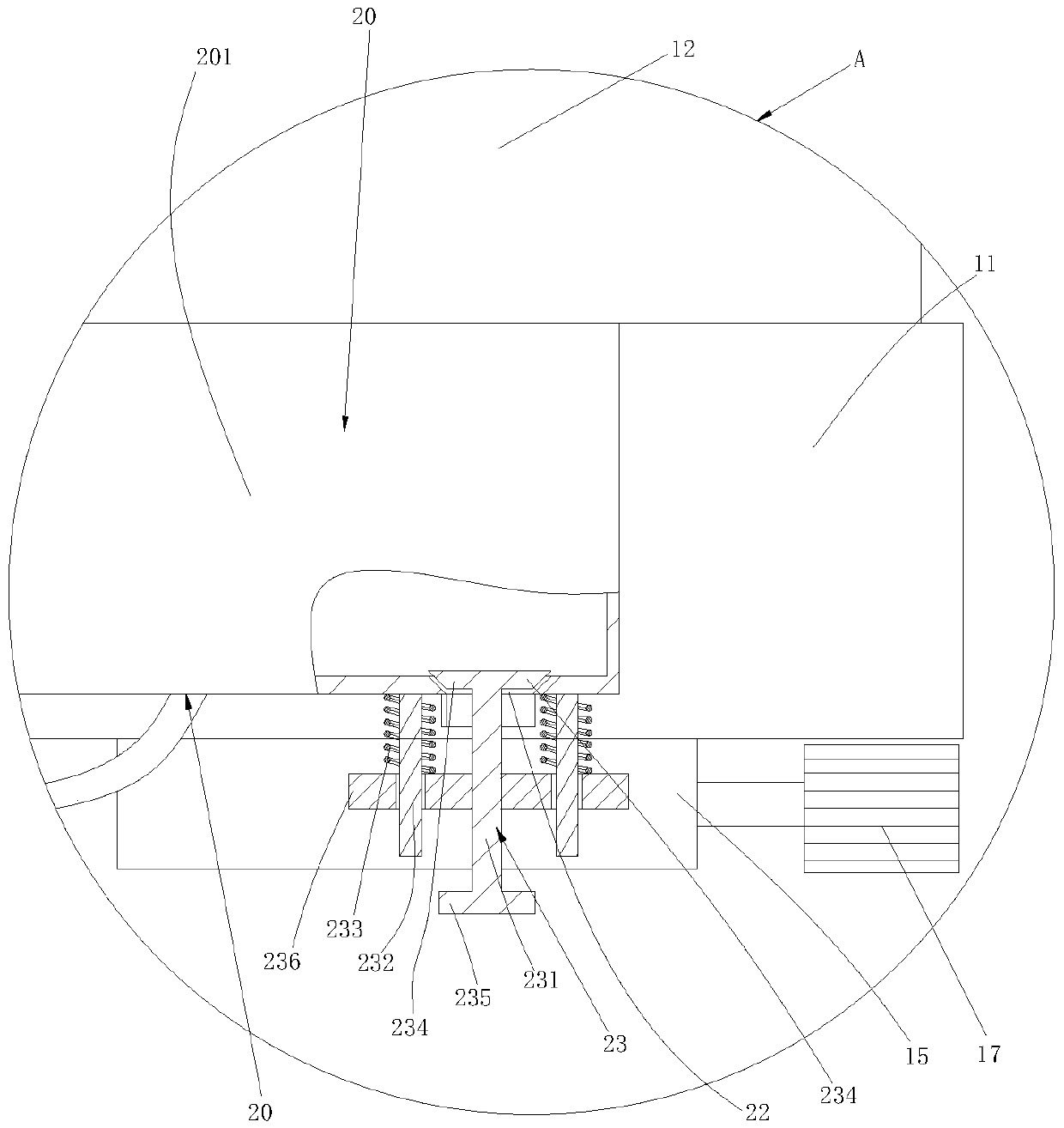

[0024] Such as figure 1 and figure 2 As shown, the track 10 includes a slide bar 101 and a toothed belt 102 , the toothed belt 102 is provided with tooth lines, and the bottom of the pallet 11 is provided with a servo motor 15 and a slider 16 that can slide on the slide bar 101 . The output shaft of the servo motor 15 is equipped with a gear 17 that can walk on the toothed belt 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com