Inner polishing device for minor-caliber steel tube

An internal polishing and small-caliber technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc., can solve the problems of difficult guarantee of processing quality, low processing efficiency, and high labor intensity, and achieve the elimination of manual labor. The effects of uneven feeding, reasonable structure setting, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

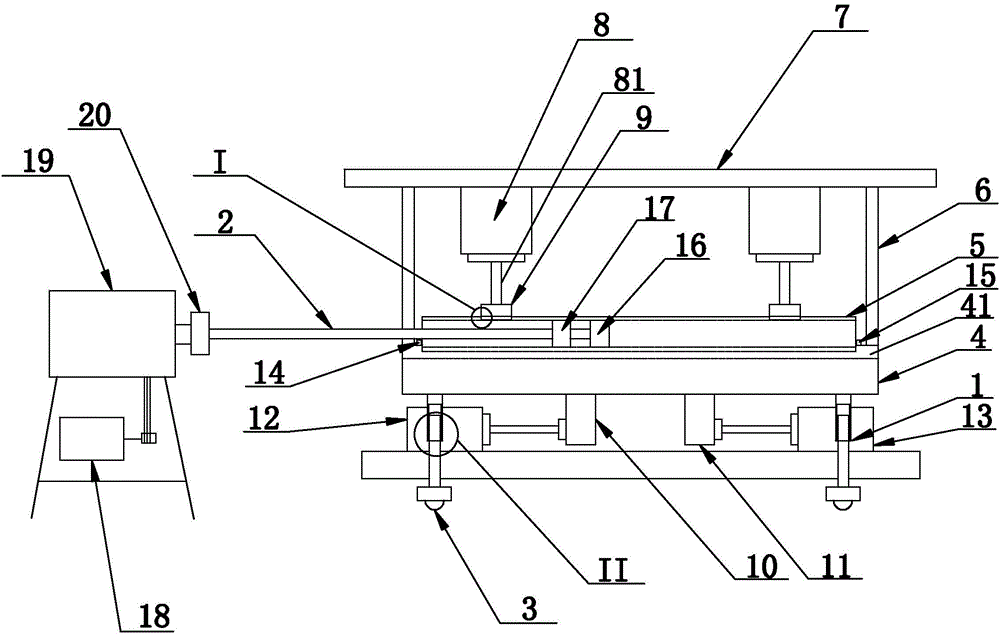

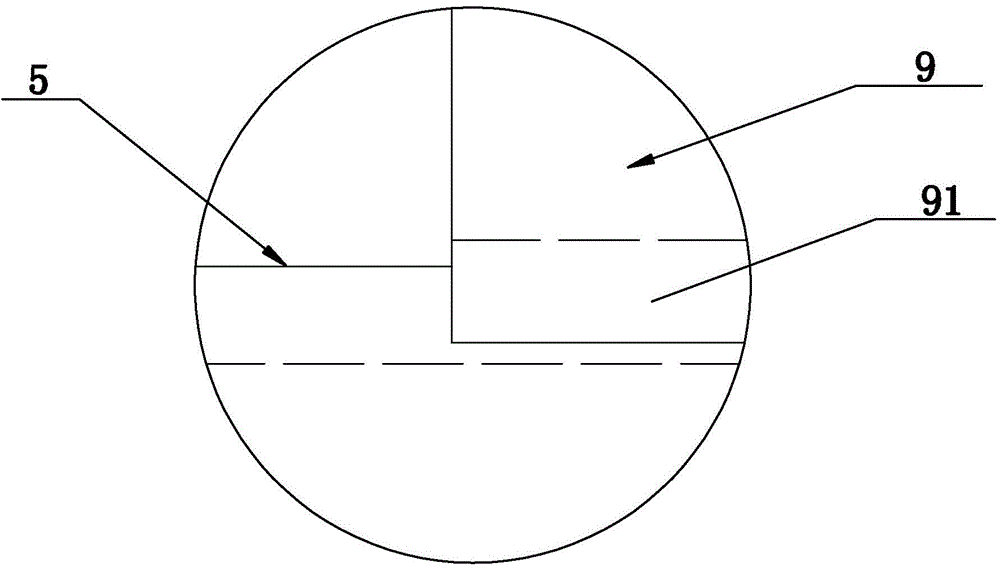

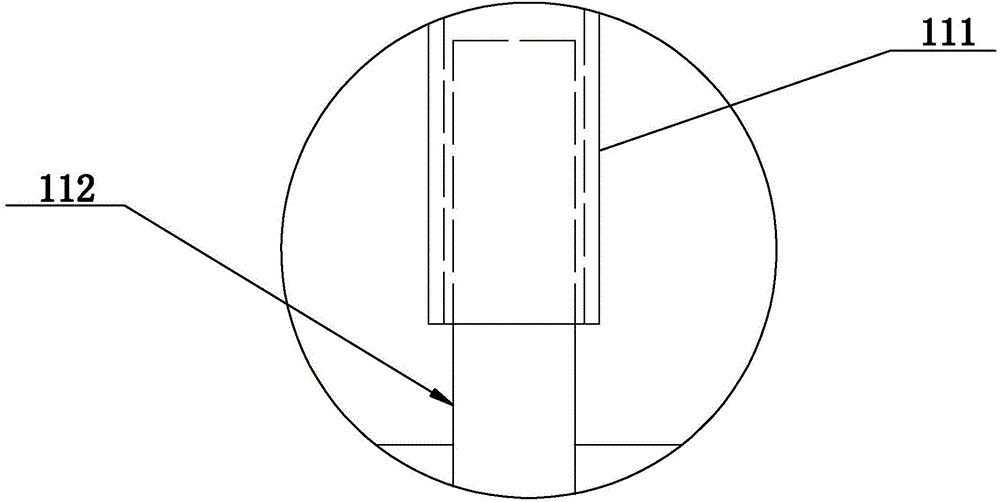

[0015] see figure 1 , figure 2 and image 3 , a small-diameter steel pipe internal polishing device disclosed by the present invention, comprising a steel pipe fixing frame 1, one end of the steel pipe fixing frame 1 is provided with a clamping rotating mechanism, a grinding rod 2 is arranged on the clamping rotating mechanism, and the end of the grinding rod 2 is provided with Grinding head, the lower end of the steel pipe fixing frame 1 is fixedly provided with a roller 3, and the upper end of the steel pipe fixing frame 1 is fixedly installed with a workbench 4, and the workbench 4 is horizontally provided with an arc-shaped steel pipe positioning groove 41, and the steel pipe positioning groove 41 A steel pipe 5 is placed inside, and the left and right ends of the workbench 4 are integrally provided with a support frame 6, and the upper ends of the two support frames 6 are integrally provided with a cylinder frame 7, and at least two steel pipe positioning cylinders 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com