High-airtightness anti-explosion shell for fuel gas detector

A technology of a gas detector and a sealed casing, which is applied in the field of detectors, can solve the problems of affecting the use of the device, reducing the safety performance of the device, and reducing the sealing performance, so as to achieve the effect of ensuring the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0019] 【Example】

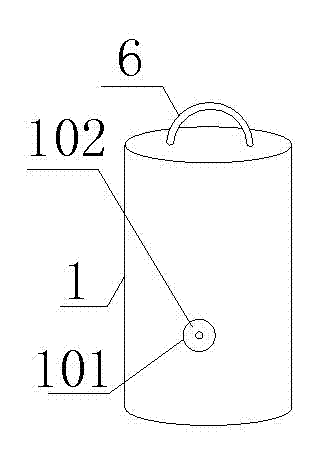

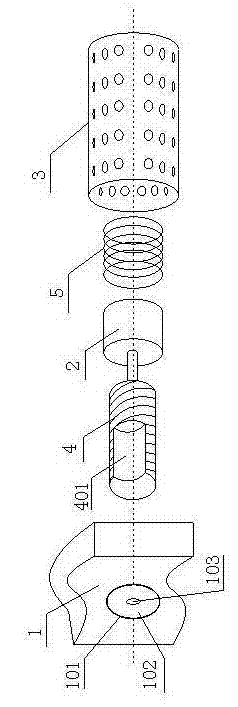

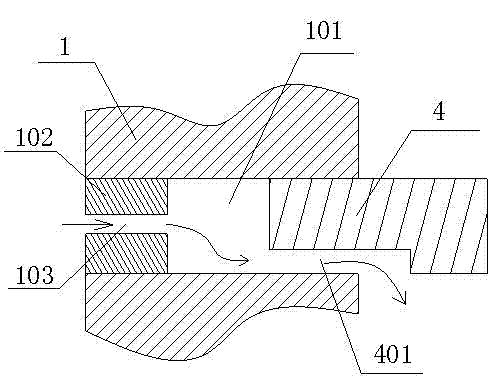

[0020] Such as Figure 1-4 As shown, the high-seal gas detector explosion-proof housing includes a sealed housing 1, including a sealed housing 1, and the sealed housing 1 is made of transparent ceramics, and the sealed housing 1 is provided with A ventilation port 101, a valve 4 is arranged at the ventilation port 101, the valve 4 is also made of ceramics, the valve 4 is cylindrical, the valve 4 matches the size of the ventilation port 101, and the two are threaded, and the valve 4 passes through The motor 2 inside the sealed housing 1 drives the rotation, and at least one air inlet groove 401 is arranged on the side wall of the valve 4, and the extending direction of the air inlet groove 401 is consistent with the axial direction of the valve 4, and the air inlet groove 401 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com