Static-dynamic balance monitoring device for routine test centrifugal machine

A routine test and dynamic balance technology, applied in the direction of static/dynamic balance test, measuring device, machine/structural component test, etc., can solve problems such as inconvenient calculation, inaccurate estimation, complex actual structure, etc., and reduce mechanical The effect of processing amount and processing difficulty, intuitive data reading, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

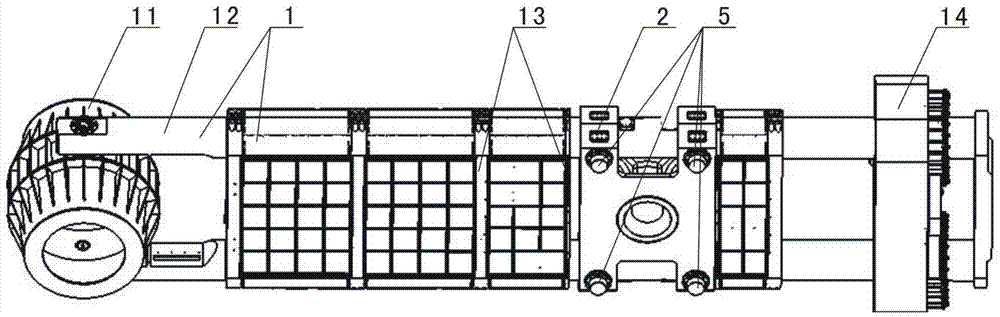

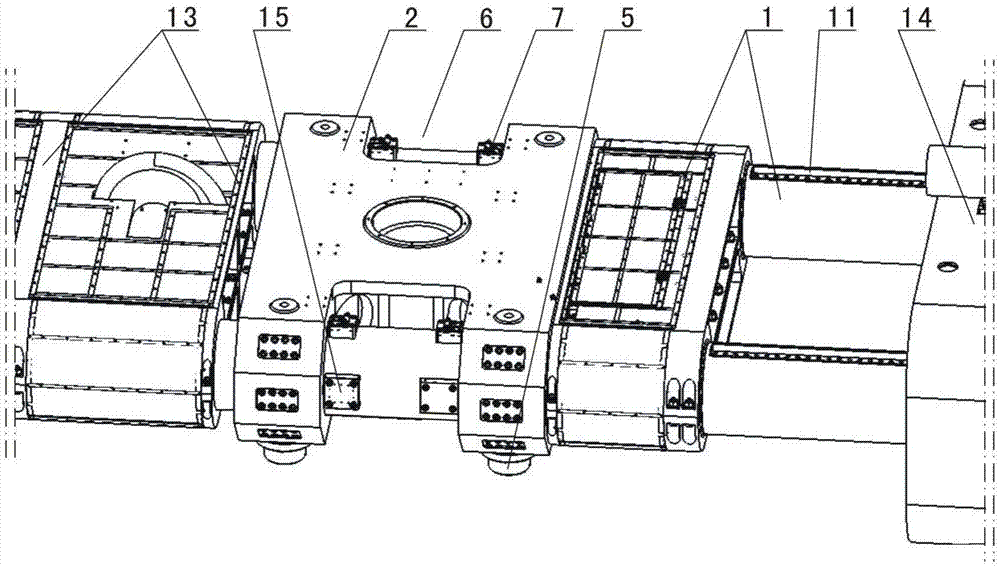

[0022] Such as figure 1 , figure 2 with image 3 As shown, in the routine test centrifuge static-dynamic balance monitoring device of the present invention, the routine test centrifuge includes a rotating arm 1, a rotating arm support 2 and a support 3, and the rotating arm 1 includes a boom and is installed respectively The test cabin 11 and the counterweight 14 at both ends of the boom, the boom includes two tension shafts 12 parallel to each other, the two tension shafts 12 are fixedly connected by a plurality of positioning rings 13, and the pivoting arm supports 2 A transverse through hole (not marked in the figure) is provided on the top, and the tension shaft 12 passes through the transverse through hole to realize connection with the pivot arm support 2, and the pivot arm support 2 is located between two adjacent positioning rings 13 so that the tension shaft 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com