Resistance and vibration reduction hydraulic ram pump

A water hammer pump and pump body technology, which is applied to pumps, machines/engines, mechanical equipment, etc., can solve problems such as abnormal operation and reduced efficiency of water hammer pumps, reduce noise and vibration, increase life, and reduce resistance The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

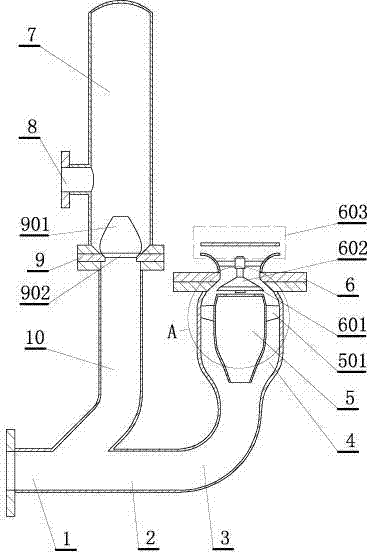

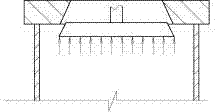

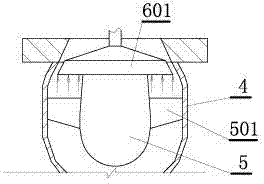

[0030] This embodiment is a water hammer pump with drag reduction and vibration reduction, such as figure 1 shown. This embodiment includes: a power pipe 1, the power pipe is connected to the pump body 2, the pump body is connected to the elbow 3, and the bottom of the vertical water inlet pipe 10, the water inlet pipe is connected to the water delivery valve 9, the The water delivery valve is connected to the air tank 7, the air tank is connected to the water outlet pipe 8, the elbow is connected to the small end of the different-diameter pipe 4 with one end large and the other end small, and the large end of the different-diameter pipe Connected with the drain valve 6, the water outlet valve disc 902 of the water delivery valve is provided with a water outlet guide body 902 on the back water surface, and the water outlet guide body is fixedly connected with the water outlet valve disc, and the drain valve of the drain valve Discharge guide body 5 is provided on the facing ...

Embodiment 2

[0044] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the drainage guide body. The discharge guide body described in this embodiment is: the head of the water-facing surface is hemispherical ( image 3 ), drum-shaped cone ( Figure 5 ), drum-shaped round table ( figure 1 ), the rear part is in the shape of a frustum with a large front end and a small rear end.

[0045] The head of the water diversion body is a hemispherical streamline shape, which is often called a nose spherical shape in three-dimensional solids. The drum-shaped cone is a cone formed by the generatrix turning on an outwardly protruding curve, and similarly, the drum-shaped cone is a circular frustum formed by the generatrix turning on an outwardly convex curve.

Embodiment 3

[0047] This embodiment is an improvement of the second embodiment, and is a refinement of the second embodiment on the drainage guide body. The drainage diversion body described in this embodiment is hollow, and the head and tail of the drainage diversion body are provided with through holes for communication, and the diameter of the rear end face circle of the drainage diversion body is less than or equal to the drainage disc The diameter of the front face.

[0048] The tail of the diversion body described in this embodiment, that is, the back water surface can adopt a fully open type or a partially shielded type. The so-called open type means that the back surface of the diversion body is not covered, and the diversion body is a thin shell structure, such as figure 1 shown. figure 1 It is a so-called shielding type, that is, there is a perforated top cover on the water surface of the diversion body.

[0049] According to the size of the acting water head H, the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com